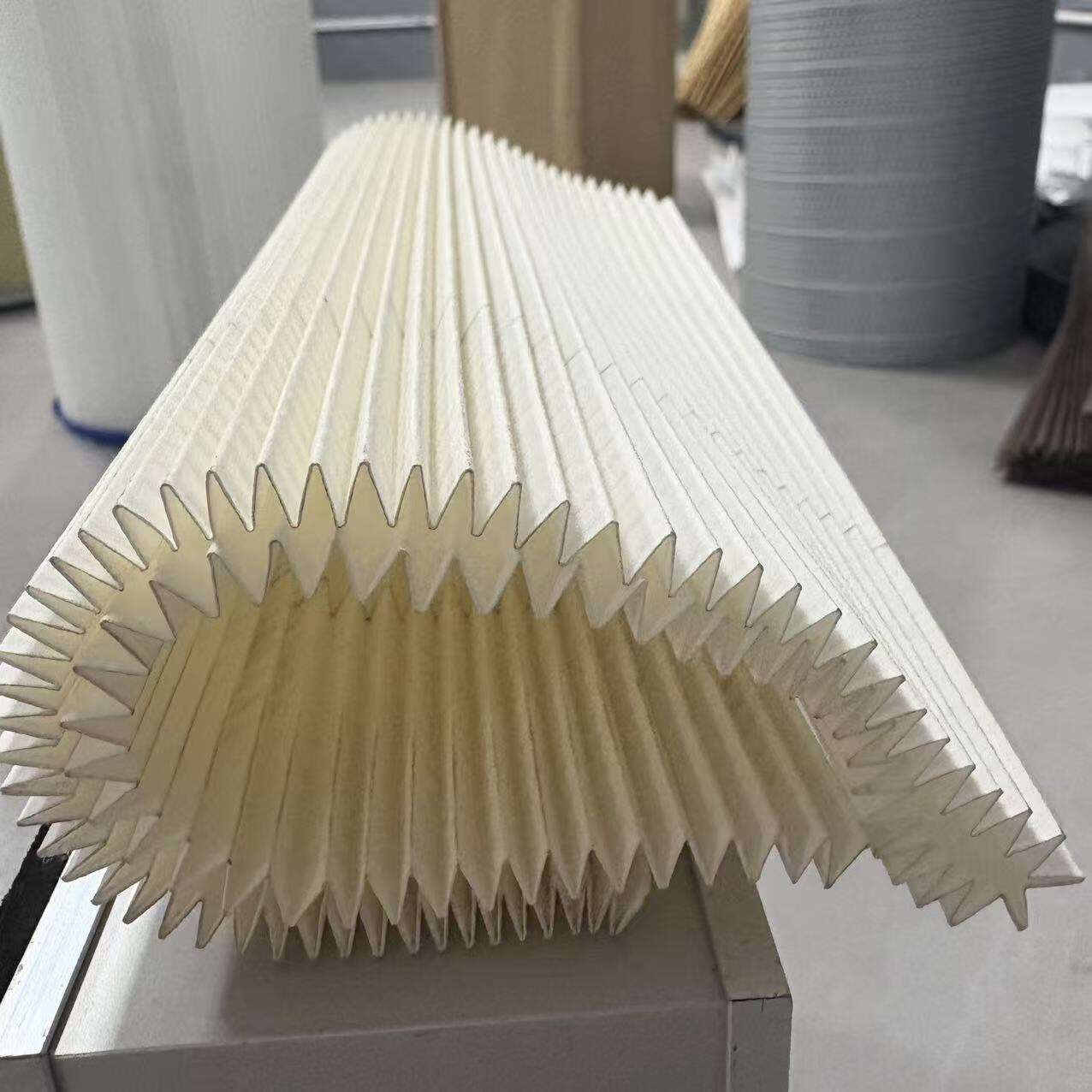

industrial mini pleating machine

The industrial mini pleating machine represents a significant advancement in filtration technology manufacturing. This compact yet powerful equipment specializes in creating precise pleats in various filter materials, combining efficiency with precision in a space-saving design. The machine operates through a sophisticated mechanical system that forms uniform pleats at adjustable depths and spacing, essential for producing high-quality filter elements. Its automated control system allows operators to set specific parameters including pleat height, spacing, and material feed rate, ensuring consistent results across production runs. The machine handles a wide range of filter media, from basic paper to advanced synthetic materials, making it versatile for different manufacturing needs. Advanced features include digital control interfaces, automatic material feeding systems, and precise cutting mechanisms that ensure clean, accurate pleating patterns. The machine's design incorporates safety features such as emergency stops and protective guards, while maintaining easy access for maintenance and material loading. With production speeds capable of handling industrial demands while maintaining precision, this equipment serves as a crucial component in filter manufacturing operations. The mini pleating machine's compact footprint makes it particularly suitable for facilities with limited space, while its robust construction ensures reliability in continuous operation.