HEPA Pleating Machine with Baffle Production LineThis production line consists of three main sections:<BR> Corrugator Section for Baffle Production Pleating Machine with Manual Operation Station AB Glue Injection & Curing SectionThe first s...

HEPA Pleating Machine with Baffle Production Line

This production line consists of three main sections:

|

|

|

Corrugator Section for Baffle Production |

Pleating Machine with Manual Operation Station |

AB Glue Injection & Curing Section |

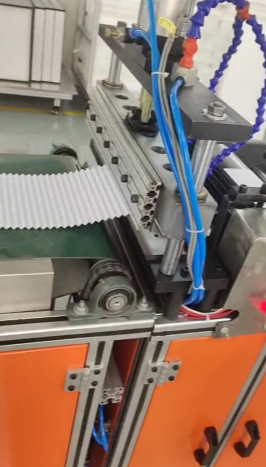

The first stage involves baffle forming using a fully automatic corrugating machine. |

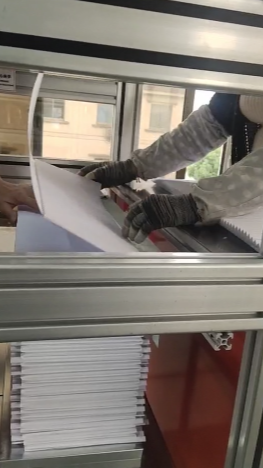

After the baffle and fiberglass media are combined, they enter the pleating process. This section uses a semi-automatic pleating machine, designed for efficiency while allowing manual adjustments when needed. |

The filter core edges are sealed using a two-component (AB) polyurethane glue injection system, ensuring structural strength and airtightness. |

The entire line is coordinated by a PLC system, with an average cycle time of ≤3 minutes per unit. Critical data (such as corrugation parameters and glue injection volume) is uploaded to the MES system for traceability. Workers are primarily responsible for material handling, quality inspection, and equipment monitoring, reflecting a flexible "human-machine collaboration" production model.

This configuration balances automation efficiency and process flexibility, making it particularly suitable for small-batch, multi-specification high-efficiency filter production.

Technical parameters

Corrugator Technical Specifications

Conveyor Length: 1.5 m

Control System:

1. Equipped with a frequency converter, counter, tension controller, temperature controller, rotary encoder, pneumatic cylinders, PLC, and touchscreen.

2. The machine uses a rotary encoder for fixed-length positioning, enabling automatic cutting, pushing, and material collection.

Pleating Machine Technical Specifications

Control System:

1. Utilizes a frequency converter, servo motor, PLC, touchscreen, sensors, and pneumatic cylinders.

2. Capable of producing different pleat heights for varying filter requirements.

3. Primarily used for folding fiberglass paper and assembling corrugated separators in HEPA filters with baffles.

AB Glue Injection Machine Technical Specifications

Working Principle:

The machine is equipped with two material tanks—one for Component A and the other for Component B. A motor-driven gear pump simultaneously injects both materials in precise proportions into the mixing head, where they are thoroughly blended via static mixing technology.

Copyright © 2026 Changzhou Fengju Machinery Equipment Co.,Ltd. All rights reserved. - Privacy policy