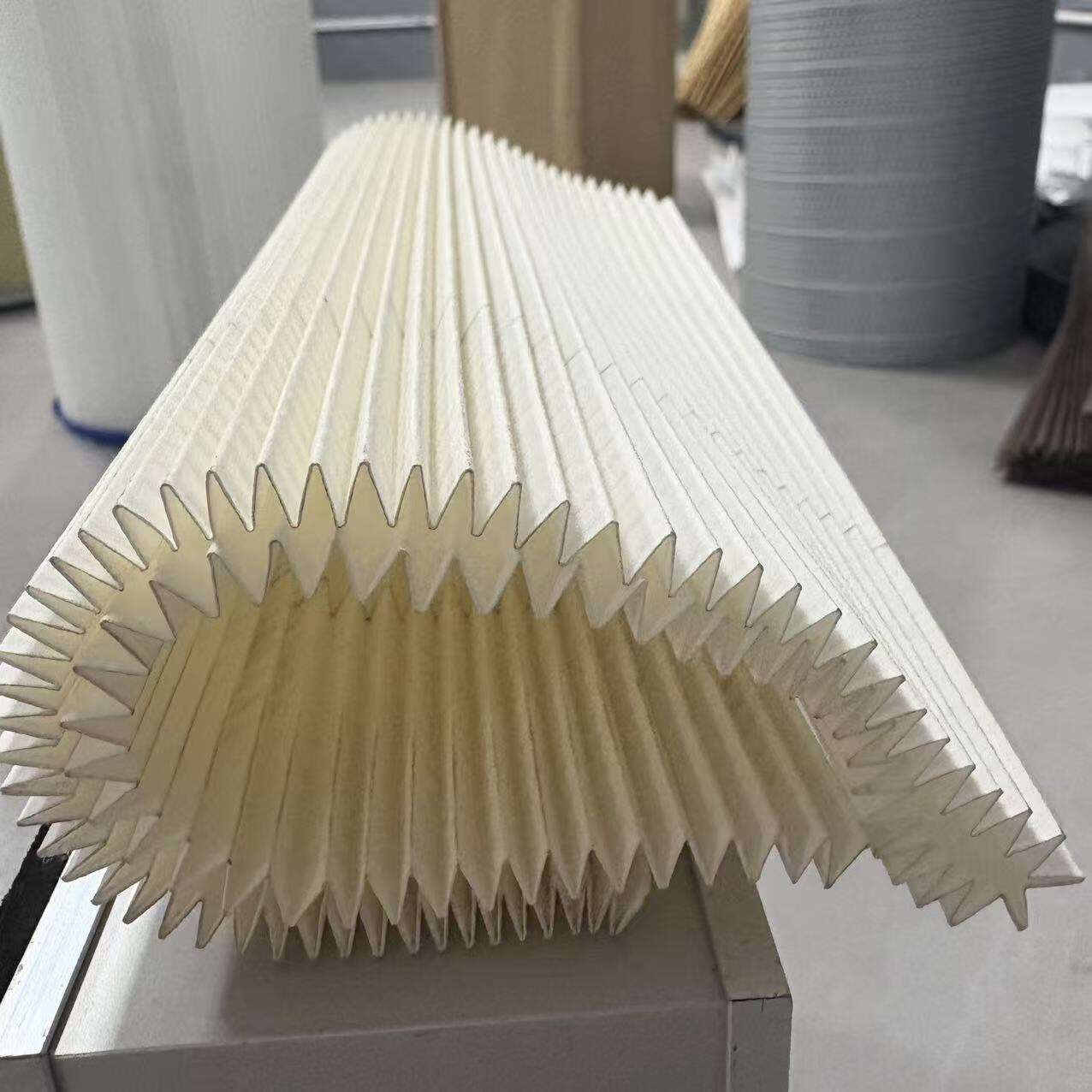

multi-layer mini pleating machine

The multi-layer mini pleating machine represents a significant advancement in filtration material processing technology. This sophisticated equipment is designed to create precise, uniform pleats in multiple layers of filter media simultaneously, dramatically improving production efficiency and consistency. The machine operates through a combination of mechanical precision and automated controls, capable of handling various filter materials including synthetic, glass fiber, and composite media. Its core technology utilizes specialized pleat forming mechanisms that maintain exact spacing and depth requirements, while the multi-layer capability allows for processing up to six layers of material concurrently. The machine features adjustable pleat height and pitch settings, ranging from 8mm to 25mm, enabling customization for different filter specifications. Advanced servo motor systems ensure smooth operation and precise material feeding, while the integrated tension control system prevents material distortion during processing. The machine's compact footprint makes it ideal for facilities with limited space, yet it delivers industrial-grade performance. Applications span across automotive filtration, HVAC systems, clean room filters, and medical grade filtration products, making it an essential tool in modern filter manufacturing operations.