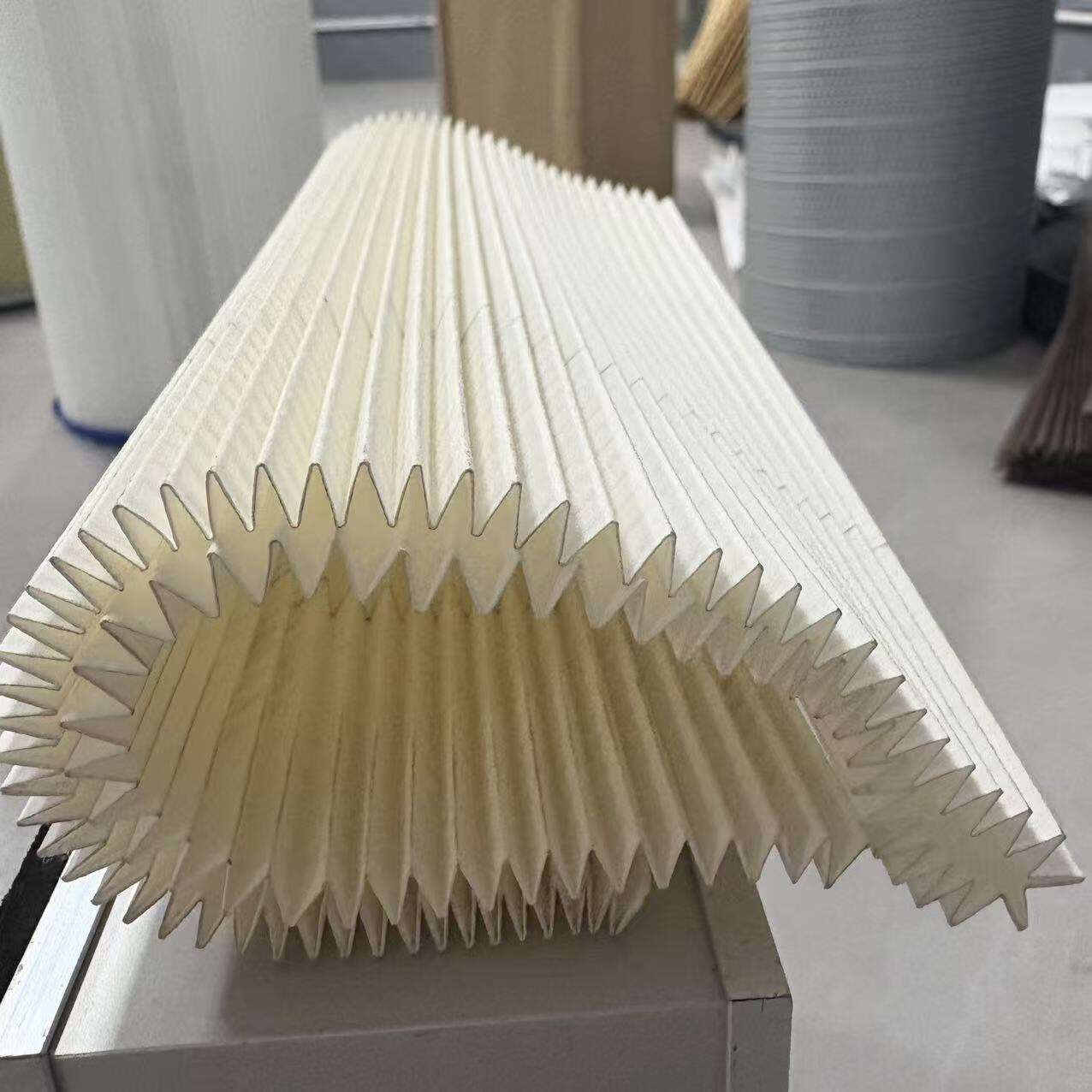

automotive mini pleating machine

The automotive mini pleating machine represents a significant advancement in filter manufacturing technology, offering precision and efficiency in a compact design. This sophisticated equipment specializes in creating uniform pleats in various filter materials, essential for automotive air and oil filters. The machine operates through a systematic process that combines mechanical precision with automated controls, enabling consistent pleat formation at high speeds. Its core functionality includes material feeding, scoring, and pleating mechanisms that work in harmony to produce precise pleats with adjustable heights and depths. The machine features advanced servo motor controls, digital monitoring systems, and adjustable speed settings to accommodate different material types and specifications. Notable technological features include automated tension control, precise pleat counting systems, and integrated quality monitoring capabilities. The equipment's versatility allows it to handle multiple filter media types, including cellulose, synthetic, and composite materials. Applications extend beyond automotive filters to include HVAC systems, industrial air purification, and specialized filtration needs. The machine's compact footprint makes it ideal for facilities with space constraints while maintaining production efficiency. With capabilities for both small batch runs and continuous operation, it meets diverse manufacturing requirements while ensuring consistent quality output.