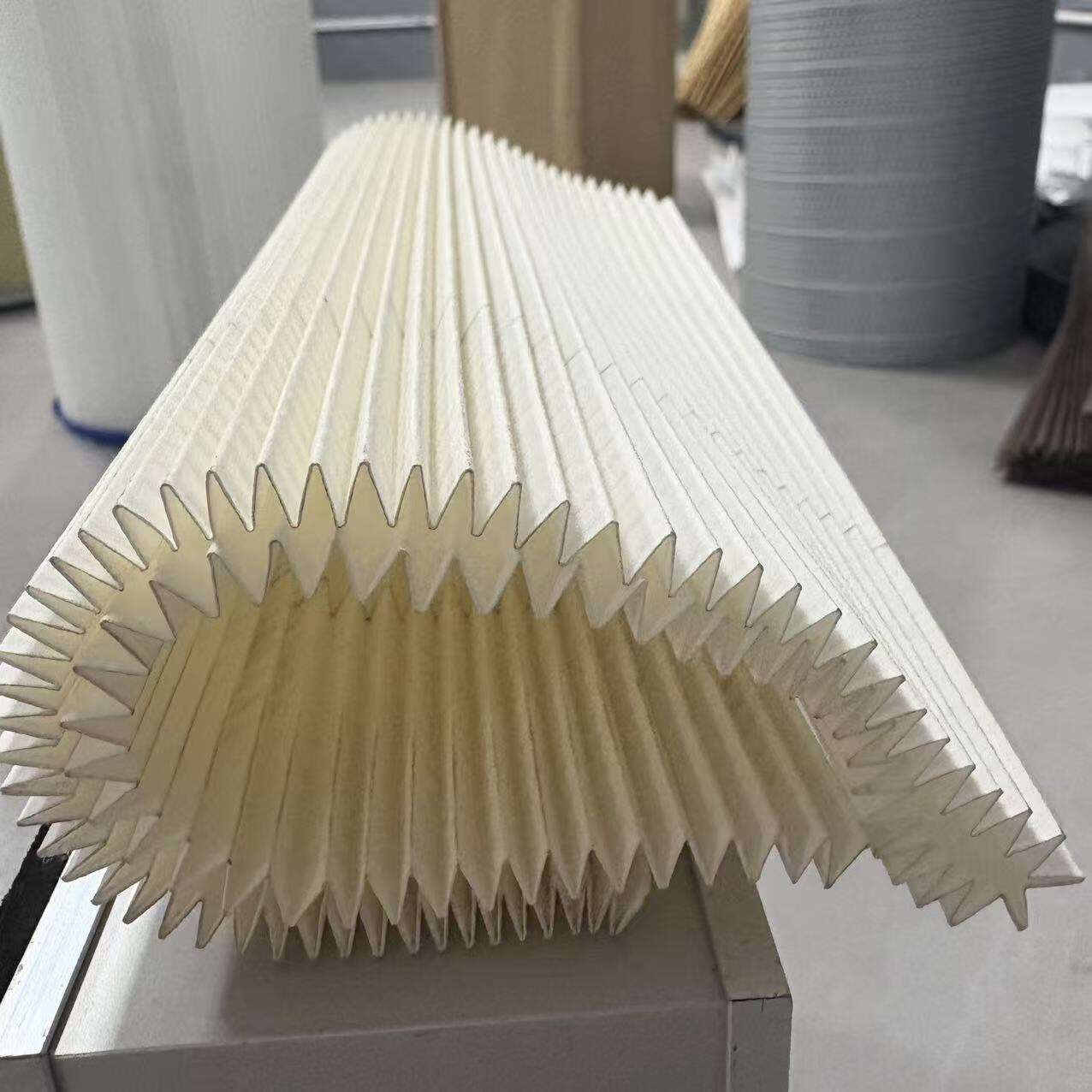

precision mini pleating machine

The precision mini pleating machine represents a significant advancement in textile processing technology, offering unparalleled accuracy and efficiency in creating precise, uniform pleats across various fabric types. This sophisticated equipment employs cutting-edge servo motor control systems and advanced digital programming interfaces to ensure consistent pleat formation with adjustable depths ranging from 1mm to 25mm. The machine's compact design makes it ideal for smaller production facilities while maintaining industrial-grade performance capabilities. It features an innovative heating system that can be precisely regulated between 20-200°C, allowing for optimal processing of different fabric compositions. The automated feed system can handle materials up to 600mm in width, with adjustable speed controls ranging from 0.5 to 12 meters per minute. The machine incorporates a user-friendly touch screen interface that enables operators to store and recall up to 100 different pleating patterns, significantly reducing setup time between production runs. Safety features include emergency stop buttons, automatic shut-off systems, and temperature monitoring to prevent fabric damage. The precision mini pleating machine's versatility makes it suitable for various applications, from fashion garments to industrial filters, demonstrating its value across multiple sectors of the textile industry.