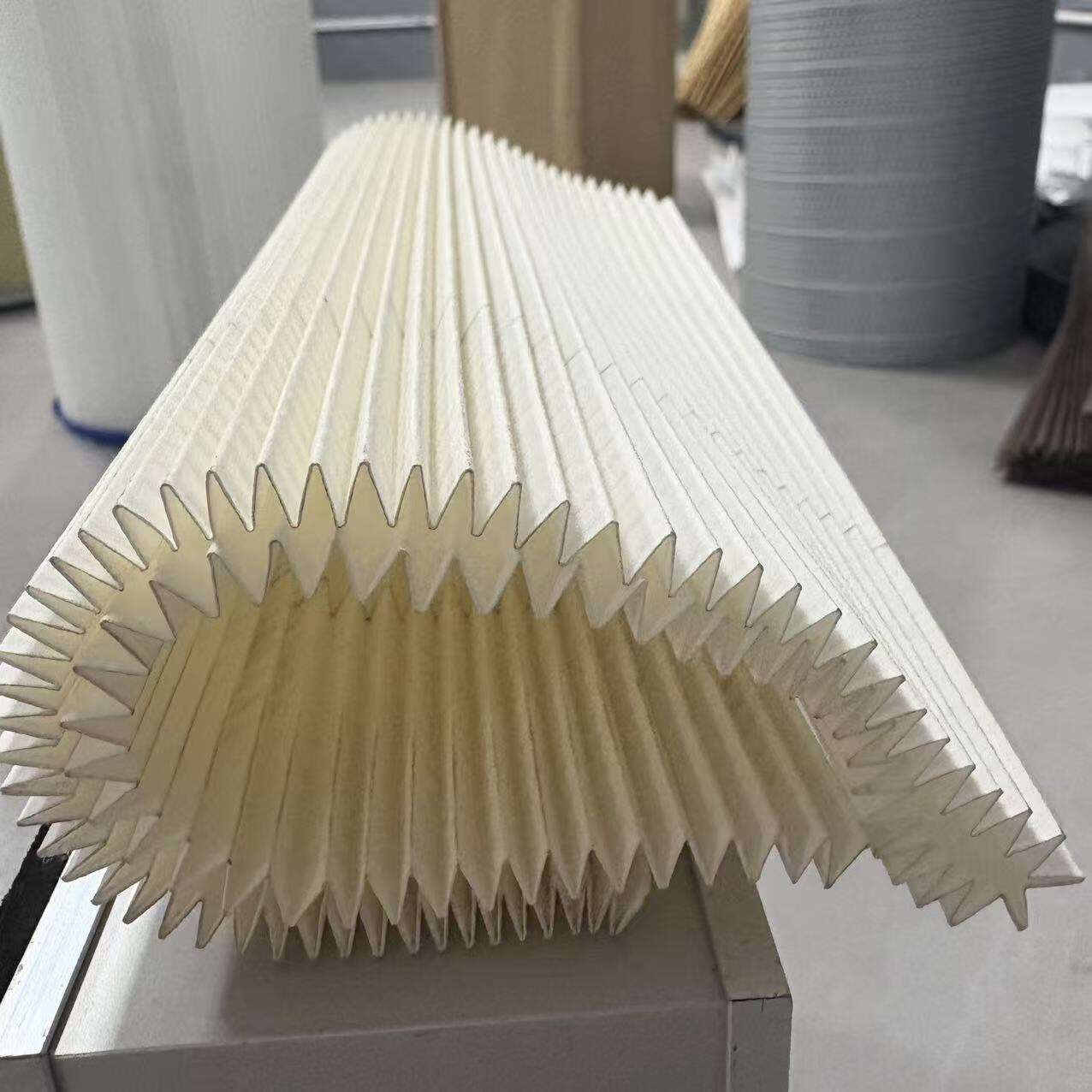

adjustable-pitch mini pleating machine

The adjustable-pitch mini pleating machine represents a significant advancement in pleating technology, offering precision and versatility in a compact design. This innovative machine enables manufacturers to create precise, uniform pleats with adjustable spacing, making it ideal for various fabric types and applications. The machine features a sophisticated digital control system that allows operators to set exact measurements for pleat depth and spacing, ensuring consistent results across production runs. Its core technology incorporates a precision-engineered pleating mechanism that maintains fabric tension while forming pleats, preventing material distortion and ensuring high-quality output. The machine's adjustable pitch functionality allows for quick transitions between different pleat sizes, ranging from fine micro-pleats to wider box pleats, all without requiring extensive machine modifications or downtime. The system includes advanced temperature control mechanisms to handle both synthetic and natural fabrics effectively, while its compact footprint makes it suitable for workshops with limited space. The machine's user-friendly interface simplifies operation and programming, enabling even operators with minimal training to achieve professional results. Additionally, its robust construction ensures longevity and reliable performance in high-volume production environments.