What Makes a Window Blind Pleating Machine Ideal for Mass Production?

A window blind pleating machine is a specialized piece of equipment designed to create precise, uniform pleats in fabric—commonly used in window treatments like window blinds, curtains, and draperies, as well as in fashion and upholstery. In mass production, where speed, consistency, and efficiency are critical, window blind pleating machines stand out as essential tools. Unlike manual pleating or less advanced machines, they streamline the pleating process, reduce errors, and handle large volumes of fabric with ease. This guide explores the features and benefits that make window blind pleating machines ideal for mass production environments.

High Speed and Productivity

One of the key reasons window blind pleating machines excel in mass production is their ability to work at high speeds, significantly increasing output compared to manual methods or slower equipment.

- Continuous Operation: window blind pleating machines are designed for continuous use, processing fabric rolls without frequent stops. Modern models can pleat fabric at speeds of 10–30 meters per minute, depending on the fabric type and pleat size. This means a single machine can produce hundreds of meters of pleated fabric in a single workday—far more than a team of workers using manual tools.

- Automated Feeding: Most machines feature automated fabric feeding systems that unroll and guide fabric through the pleating mechanism smoothly. This eliminates the need for manual feeding, which is slow and prone to interruptions. The fabric moves consistently through the machine, ensuring a steady production flow.

- Quick Setup: While initial setup may take time to configure pleat sizes and patterns, once programmed, window blind pleating machines can switch between jobs quickly. This reduces downtime between production runs, a critical factor in mass production where every minute counts.

For manufacturers handling large orders, the high speed of window blind pleating machines ensures deadlines are met without sacrificing quality.

Consistent and Uniform Pleats

In mass production, consistency is non-negotiable—customers expect every product to look identical, whether it’s the first or the thousandth item. window blind pleating machines deliver unmatched uniformity in pleats.

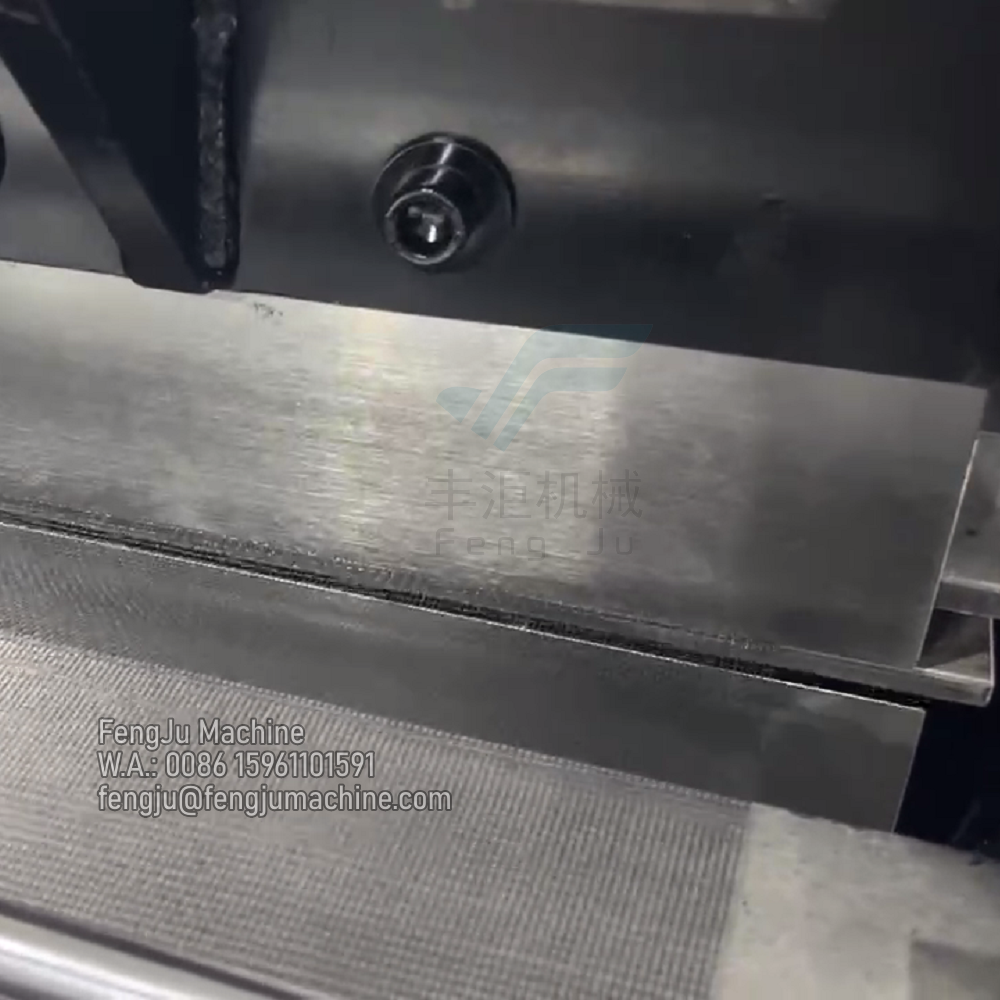

- Precision Engineering: These machines use advanced mechanisms, such as rotating blades, folding plates, or ultrasonic technology, to create pleats with exact dimensions. Pleat depth, width, and spacing can be programmed to within millimeters, ensuring every pleat matches the design specifications.

- Reduced Human Error: Manual pleating relies on workers’ skill and attention to detail, leading to variations in pleat size or alignment. window blind pleating machines eliminate this risk by following preprogrammed settings, producing identical pleats across entire fabric rolls.

- Adaptable to Fabric Types: Whether working with lightweight cotton, heavy linen, or delicate polyester, modern window blind pleating machines adjust tension and speed to suit the fabric. This adaptability ensures consistent pleats even when switching between materials, a common requirement in mass production.

Uniform pleats enhance the visual appeal of products, build customer trust, and reduce the need for quality checks or rework.

Versatility in Pleat Designs

Mass production often requires handling multiple product lines or custom orders, and window blind pleating machines offer the versatility to meet diverse design needs.

- Customizable Pleat Patterns: Operators can program machines to create various pleat styles, including pinch pleats, box pleats, goblet pleats, or sunburst pleats. This flexibility allows manufacturers to produce different products on the same machine, from standard window window blinds to high-end draperies.

- Adjustable Sizes: Pleat depth (from 5mm to 50mm or more) and spacing can be easily adjusted via digital controls. This means a single machine can switch from producing small, tight pleats for lightweight curtains to larger, spaced pleats for heavy upholstery fabric.

- Compatibility with Attachments: Many window blind pleating machines work with additional tools, such as cutting blades or hemming attachments, to complete multiple steps in one pass. For example, a machine can pleat fabric and then cut it to the required length, reducing the need for separate processing stages.

This versatility makes window blind pleating machines a cost-effective choice for manufacturers handling varied product lines, as they eliminate the need for multiple specialized machines.

Labor Efficiency and Cost Savings

Mass production thrives on reducing labor costs while maintaining output, and window blind pleating machines contribute significantly to this goal.

- Reduced Workforce Needs: A single operator can monitor and operate a window blind pleating machine, replacing multiple workers needed for manual pleating. This cuts down on labor expenses, a major cost in manufacturing.

- Lower Training Requirements: While operators need basic training to set up and maintain the machine, they don’t require the specialized skills of manual pleating experts. This simplifies hiring and reduces training time, especially in high-turnover industries.

- Minimized Rework: The precision of window blind pleating machines reduces the number of defective products, which would otherwise require rework or disposal. This saves both time and material costs, improving overall efficiency.

For manufacturers scaling up production, the labor savings from using window blind pleating machines directly boost profitability.

Integration with Production Lines

window blind pleating machines are designed to fit seamlessly into automated production lines, a key feature for mass production environments.

- Conveyor System Compatibility: Many models connect to conveyor belts, allowing pleated fabric to move directly to the next stage of production, such as cutting, sewing, or packaging. This creates a continuous workflow with minimal manual handling.

- Digital Control Systems: Modern machines use digital interfaces that integrate with factory management software. Operators can monitor production data (like meters pleated, speed, and error rates) in real time, enabling quick adjustments to optimize output.

- Space Efficiency: Compact designs mean window blind pleating machines fit into tight production layouts, maximizing floor space in factories. This is especially important for mass production facilities where space is often limited.

Integration with production lines reduces bottlenecks, speeds up the manufacturing process, and ensures a smooth flow from fabric input to finished product.

Durability for Heavy-Duty Use

Mass production demands equipment that can withstand long hours of operation, and window blind pleating machines are built for durability.

- Robust Construction: These machines feature heavy-duty frames, high-quality metals, and reinforced moving parts that resist wear and tear. They can operate 8–12 hours a day, 5–6 days a week, without frequent breakdowns.

- Low Maintenance Requirements: While regular maintenance (like cleaning and lubrication) is needed, window blind pleating machines have fewer moving parts than complex textile machines, reducing the risk of mechanical failures. This minimizes downtime for repairs.

- Long Lifespan: With proper care, a window blind pleating machine can last 10–15 years, making it a long-term investment for manufacturers. This longevity ensures consistent production capacity over time, even for high-volume orders.

Durability is critical in mass production, where equipment failures can halt entire production lines and lead to missed deadlines.

FAQ

What types of fabric can a window blind pleating machine handle?

window blind pleating machines work with most fabrics, including cotton, polyester, linen, silk, and lightweight synthetics. Some heavy-duty models can also handle thicker materials like upholstery fabric or vinyl, though settings may need adjustment.

How long does it take to set up a window blind pleating machine for a new pleat design?

Setup times vary but typically range from 10–30 minutes for most designs. Digital machines with presets allow operators to save settings, reducing setup time for repeat orders to just a few minutes.

Can window blind pleating machines produce custom pleat patterns for small orders?

Yes, but they are most cost-effective for large orders. While machines can handle custom patterns, the setup time makes them less ideal for very small batches compared to manual methods.

Do window blind pleating machines require skilled operators?

Basic training is needed to operate and maintain the machine, but operators don’t need advanced textile skills. Manufacturers usually provide training on programming settings, troubleshooting, and safety.

What is the average cost of a window blind pleating machine?

Costs range from $5,000 for small, entry-level models to $50,000+ for large, industrial machines with advanced features. The investment is justified by increased productivity and reduced labor costs in mass production.

Table of Contents

- What Makes a Window Blind Pleating Machine Ideal for Mass Production?

- High Speed and Productivity

- Consistent and Uniform Pleats

- Versatility in Pleat Designs

- Labor Efficiency and Cost Savings

- Integration with Production Lines

- Durability for Heavy-Duty Use

-

FAQ

- What types of fabric can a window blind pleating machine handle?

- How long does it take to set up a window blind pleating machine for a new pleat design?

- Can window blind pleating machines produce custom pleat patterns for small orders?

- Do window blind pleating machines require skilled operators?

- What is the average cost of a window blind pleating machine?