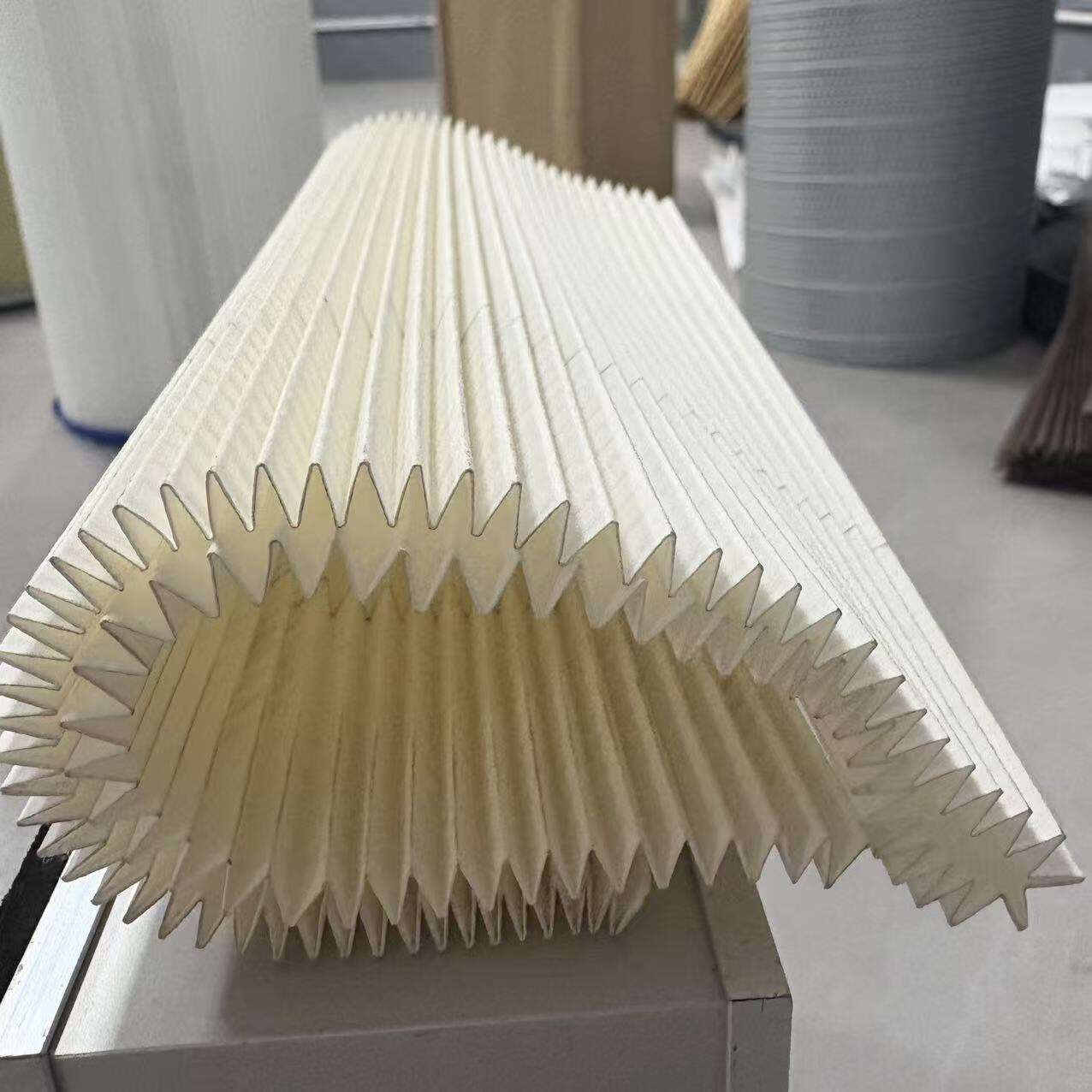

commercial mini pleating machine

The commercial mini pleating machine represents a significant advancement in textile processing technology, offering a compact yet powerful solution for creating precise pleats in various fabric materials. This innovative device combines efficiency with versatility, capable of producing different pleat styles including knife pleats, box pleats, and accordion pleats. The machine features an advanced digital control system that ensures consistent pleat depth and spacing, while its adjustable temperature settings accommodate different fabric types from lightweight chiffons to heavier materials like wool blends. The automated feed system maintains fabric tension for uniform pleating results, while the precision-engineered heating element ensures even heat distribution across the pleating surface. Operating at speeds of up to 20 meters per hour, this compact machine occupies minimal floor space while delivering professional-grade results. Its user-friendly interface allows operators to easily program and store multiple pleating patterns, making it ideal for both small-scale production and larger commercial operations. The machine includes safety features such as emergency stop buttons and temperature control mechanisms, ensuring safe operation while maintaining high productivity levels.