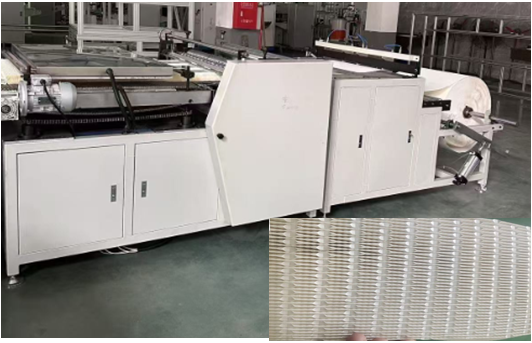

tube rolling machine

A tube rolling machine is an advanced manufacturing equipment designed to produce seamless pipes and tubes with precise dimensional accuracy and superior surface finish. This versatile machine utilizes rotary motion and controlled pressure to form metal tubes from solid billets or hollow shells. The process involves heating the material to optimal temperature before passing it through a series of rotating rolls that gradually reduce the wall thickness while increasing length. Modern tube rolling machines incorporate sophisticated control systems that enable real-time monitoring of parameters such as temperature, pressure, and rotation speed, ensuring consistent quality throughout the production run. These machines can process various materials including carbon steel, stainless steel, aluminum, and copper alloys. The technology employs both hot and cold rolling methods, depending on the material specifications and end-use requirements. With adjustable roll configurations and multiple pass options, operators can achieve different diameter ranges and wall thicknesses to meet diverse industrial specifications. The machine's automated features include material handling systems, cooling mechanisms, and quality inspection tools, making it an essential component in modern tube manufacturing facilities.