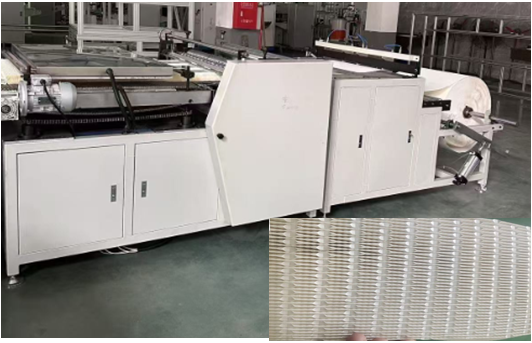

custom air filter making machine

The custom air filter making machine represents a cutting-edge solution in industrial filtration manufacturing. This sophisticated equipment combines precision engineering with automated processes to produce high-quality air filters tailored to specific requirements. The machine features advanced pleating technology that ensures consistent fold patterns and optimal filter media utilization, while its computerized control system enables precise adjustments for different filter specifications. The equipment incorporates multiple stations including media feeding, pleating, frame assembly, and quality inspection phases, all integrated into a streamlined production line. Its versatile design accommodates various filter media types, from standard fiberglass to specialized synthetic materials, making it suitable for producing automotive, HVAC, and industrial-grade filters. The machine's automated measuring and cutting systems ensure accurate dimensioning, while the hot-melt adhesive application system guarantees secure filter assembly. With production speeds capable of meeting high-volume demands while maintaining consistent quality, this machine represents a significant advancement in filter manufacturing technology. The integration of smart sensors and real-time monitoring capabilities ensures optimal performance and minimal material waste, while the user-friendly interface allows for quick adjustments and program modifications to meet varying production requirements.