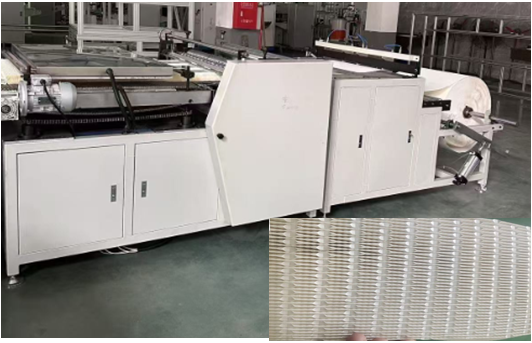

multi-layer air filter making machine

The multi-layer air filter making machine represents a cutting-edge solution in air filtration manufacturing technology. This sophisticated equipment is designed to produce high-quality, multi-layer air filters through an automated and precise manufacturing process. The machine integrates multiple production stages, including material feeding, pleating, cutting, frame assembly, and quality inspection, all within a single automated system. It can handle various filter materials such as meltblown fabric, activated carbon layers, and synthetic fibers, creating filters with multiple filtration stages for enhanced performance. The machine's advanced control system ensures consistent production quality while maintaining high efficiency, capable of producing hundreds of filter units per hour. Its versatile design accommodates different filter sizes and configurations, making it suitable for manufacturing various types of air filters, from HVAC systems to industrial applications. The machine features precision control mechanisms that maintain exact spacing between pleats and ensure uniform material distribution across all layers. Additionally, it incorporates real-time monitoring systems that track production parameters and material usage, optimizing resource utilization and minimizing waste. The equipment's modular design allows for easy maintenance and quick configuration changes, reducing downtime and increasing overall operational efficiency.