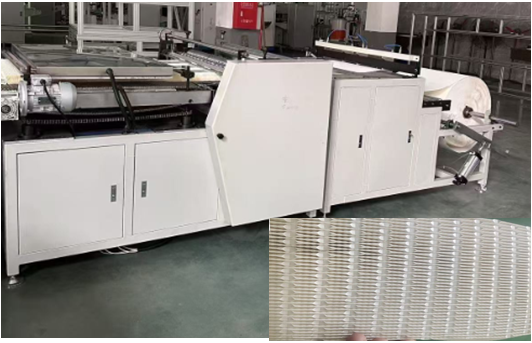

motorized air filter making machine

The motorized air filter making machine represents a significant advancement in air filtration manufacturing technology. This sophisticated equipment automates the entire process of producing high-quality air filters, from material feeding to final product packaging. The machine incorporates a precision-driven motor system that ensures consistent operation and uniform filter production. It features advanced pleating technology that creates precise folds in filter media, maximizing the surface area for optimal filtration efficiency. The machine's automated cutting and sealing mechanisms maintain precise dimensions and secure edges, while its integrated quality control systems monitor production parameters in real-time. Capable of producing various filter sizes and styles, the machine accommodates different filter media materials, including synthetic fibers, glass fiber, and activated carbon-infused materials. Its modular design allows for quick changeovers between different filter specifications, making it ideal for both large-scale production runs and customized orders. The machine's digital control interface enables operators to adjust settings easily and monitor production metrics, while its safety features ensure worker protection during operation. This versatile equipment serves industries ranging from automotive and HVAC to medical and industrial applications, delivering consistent quality and operational efficiency in filter manufacturing.