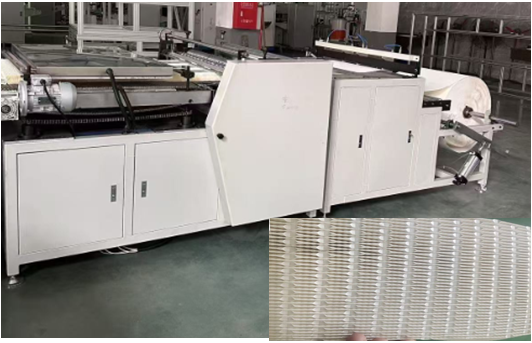

car air filter making machine

The car air filter making machine represents a significant advancement in automotive component manufacturing technology. This sophisticated equipment is designed to produce high-quality air filters essential for vehicle performance and engine protection. The machine incorporates multiple specialized stations including material feeding, pleating, frame assembly, and quality inspection systems. Its automated production line ensures consistent output while maintaining precise pleating patterns and optimal filter media distribution. The machine can process various filter materials including synthetic fibers, cellulose, and hybrid combinations, accommodating different specifications and performance requirements. Advanced control systems enable real-time monitoring of production parameters, ensuring each filter meets strict quality standards. The equipment features adjustable settings for different filter sizes and designs, making it versatile for various vehicle models and specifications. With production speeds capable of reaching up to 1000 units per hour, the machine maintains high efficiency while ensuring product integrity. Integration of smart sensors and quality control mechanisms throughout the production process minimizes defects and material waste.