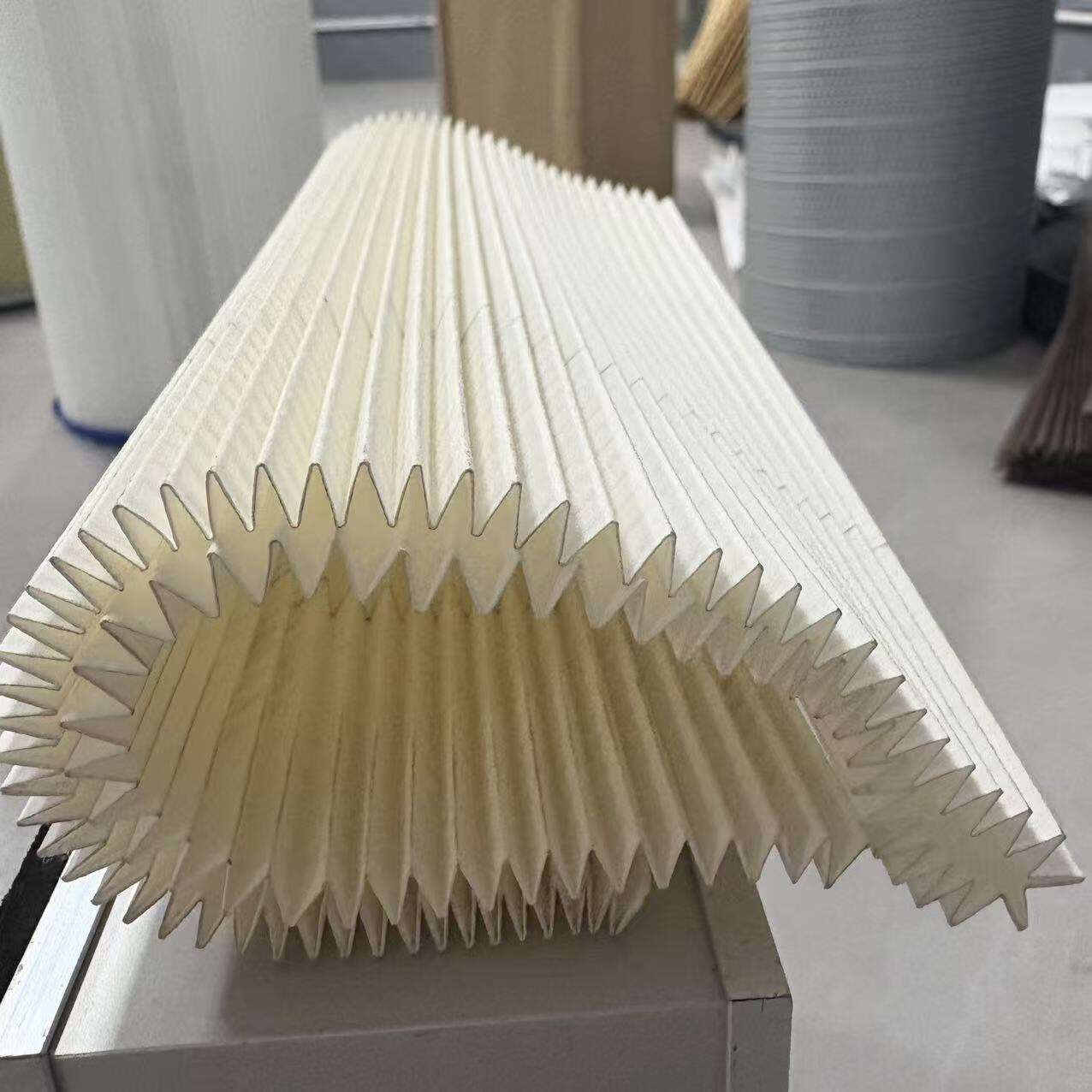

custom mini pleating machine

The custom mini pleating machine represents a significant advancement in fabric processing technology, offering precise and efficient pleating capabilities in a compact form factor. This innovative machine combines sophisticated mechanical engineering with user-friendly controls to deliver consistent, high-quality pleats across various fabric types. At its core, the machine features an adjustable pleating mechanism that can create pleats ranging from 1mm to 25mm in width, making it versatile for different applications. The machine's temperature control system maintains optimal heat distribution, ensuring crisp, durable pleats while protecting delicate materials. Its automated feed system guarantees uniform pleat spacing and depth, significantly reducing human error and material waste. The custom mini pleating machine is equipped with digital controls for precise parameter adjustments, allowing operators to save and recall specific settings for different fabric types and pleat styles. Its compact design makes it ideal for smaller workshops and design studios while maintaining industrial-grade performance capabilities. The machine excels in processing various materials, including lightweight fabrics, synthetics, and natural fibers, making it suitable for fashion design, home textiles, and specialized industrial applications.