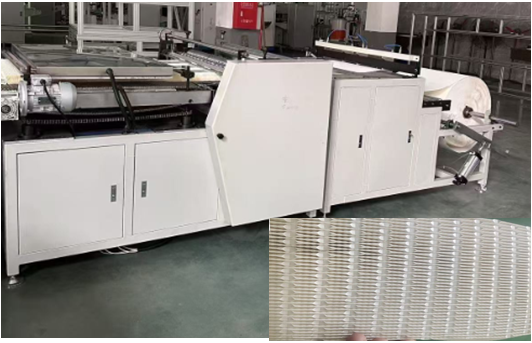

pleating and assembly air filter making machine

The pleating and assembly air filter making machine represents a cutting-edge solution in air filtration manufacturing technology. This sophisticated equipment seamlessly combines pleating and assembly operations to produce high-quality air filters with precision and efficiency. The machine features advanced pleating mechanisms that create uniform, precise folds in filter media, ensuring optimal surface area for maximum filtration effectiveness. Its automated assembly system integrates multiple components, including frame attachment, sealant application, and media positioning, into a streamlined production process. The machine's versatile design accommodates various filter media types and sizes, making it suitable for manufacturing automotive, HVAC, industrial, and commercial air filters. Essential technological features include computerized pleat depth control, automated material feeding systems, and quality monitoring sensors that maintain consistent production standards. The machine's modular construction allows for easy maintenance and quick adjustments to meet different production requirements. With production speeds capable of handling industrial-scale demands, this equipment significantly reduces manual labor while maintaining high-quality output. The system includes advanced safety features and user-friendly controls, making it accessible for operators of varying skill levels.