hepa pleating machine without baffle

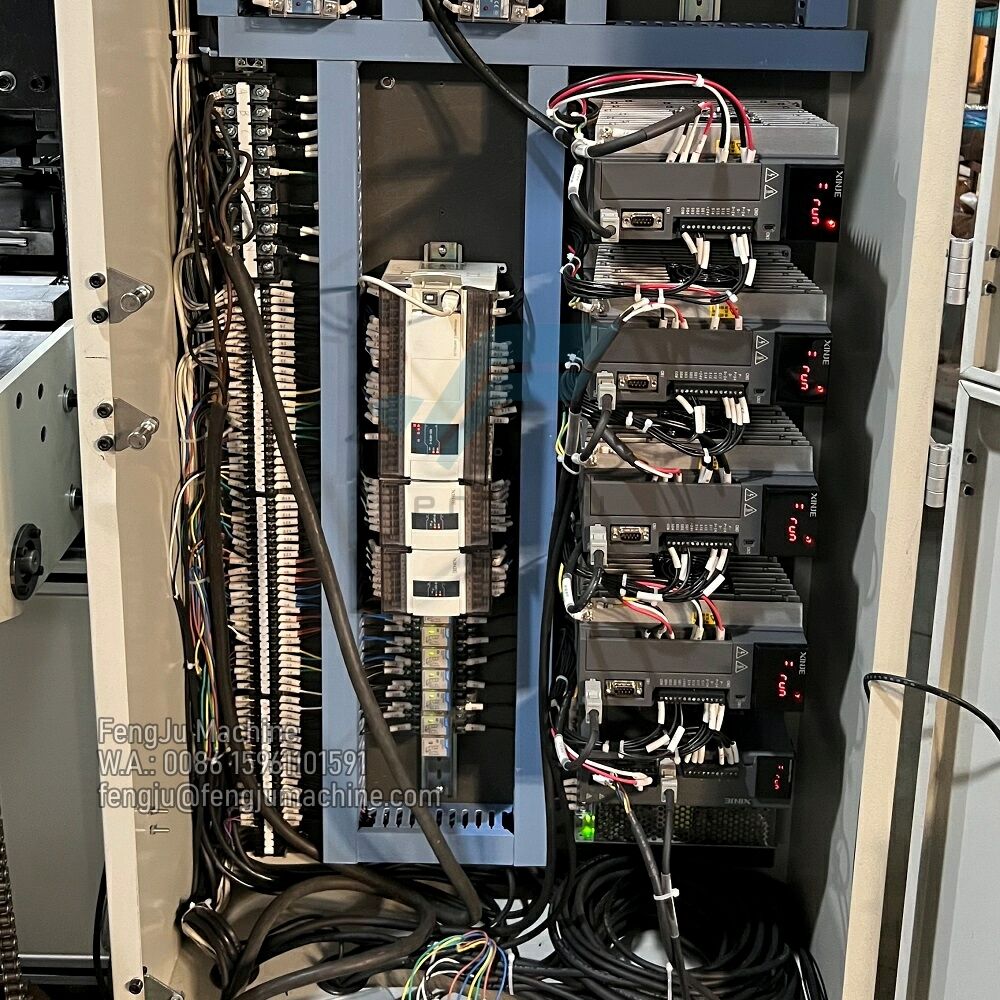

The HEPA pleating machine without baffle represents a significant advancement in air filter manufacturing technology. This innovative equipment is specifically designed for the precise and efficient production of high efficiency particulate air (HEPA) filter pleats without the need for traditional baffle systems. The machine utilizes advanced servo motor control systems to ensure accurate pleat formation and consistent spacing, resulting in superior filter performance. Its automated operation encompasses multiple stages, including material feeding, scoring, pleating, and collection, all seamlessly integrated into a single production line. The machine can handle various filter media materials, including glass fiber, synthetic fiber, and composite materials, with adjustable pleat heights ranging from 20mm to 100mm. Operating at speeds of up to 15 meters per minute, it maintains exceptional precision in pleat geometry and spacing. The absence of baffles simplifies maintenance requirements and reduces potential points of failure, while also allowing for greater flexibility in pleat designs. The system includes real time monitoring capabilities for quality control and production efficiency tracking, making it ideal for both large scale manufacturing operations and specialized filter production facilities.