filter paper pleating machine manufacturers

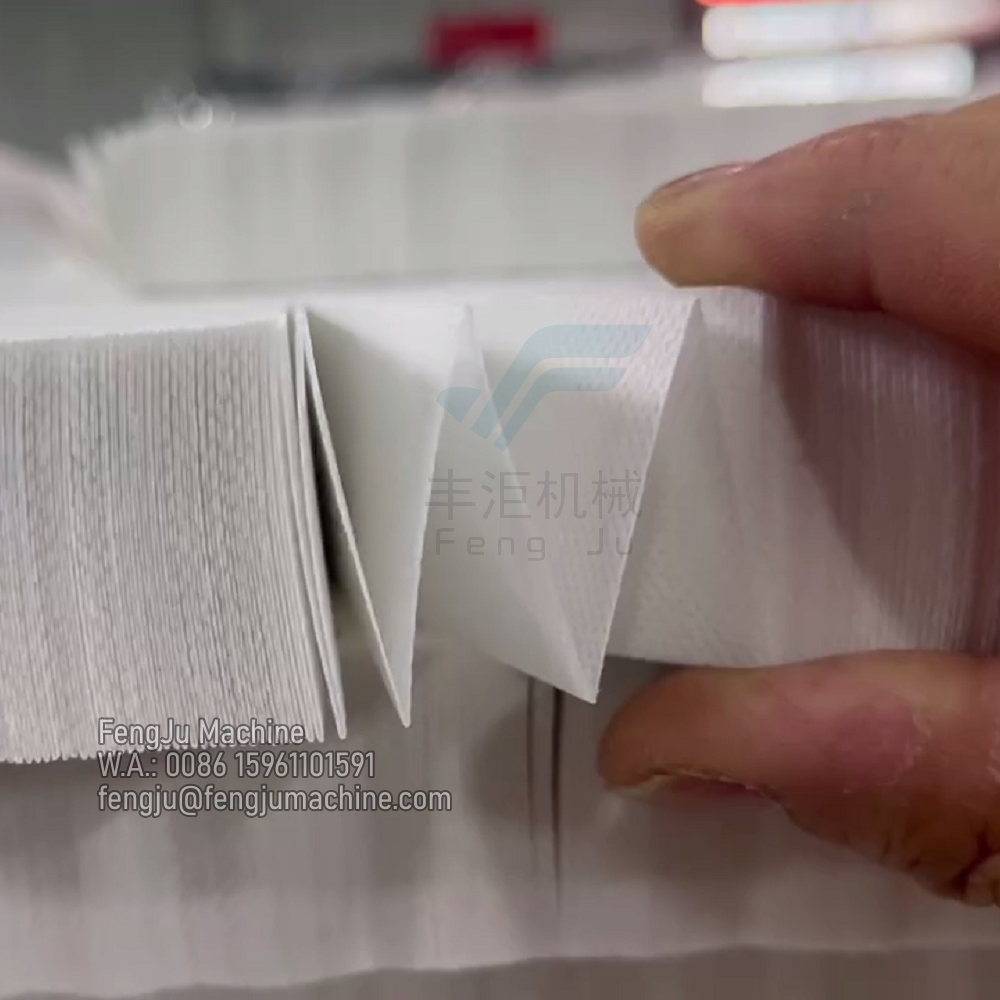

Filter paper pleating machine manufacturers are industry leaders in producing sophisticated equipment essential for the production of various filtration products. These manufacturers develop and produce machines that create precise pleats in filter media, a crucial process in manufacturing air filters, oil filters, and other filtration systems. The machines incorporate advanced technological features such as automated pleat counting systems, precision depth control, and variable speed capabilities to ensure consistent pleat formation. Modern filter paper pleating machines typically include computerized controls for exact pleat spacing and height adjustments, enabling manufacturers to meet diverse specifications for different filtration applications. These manufacturers also integrate quality control systems that monitor pleat uniformity and material integrity throughout the production process. The equipment is designed to handle various filter media materials, from traditional cellulose to synthetic materials and specialized composite materials. Many manufacturers offer customization options to accommodate specific production requirements, including different pleat heights, spacing, and production speeds. Their machines often feature quick-change tooling systems for rapid production changeovers and minimal downtime. The manufacturers provide comprehensive technical support, maintenance services, and training programs to ensure optimal machine performance and longevity.