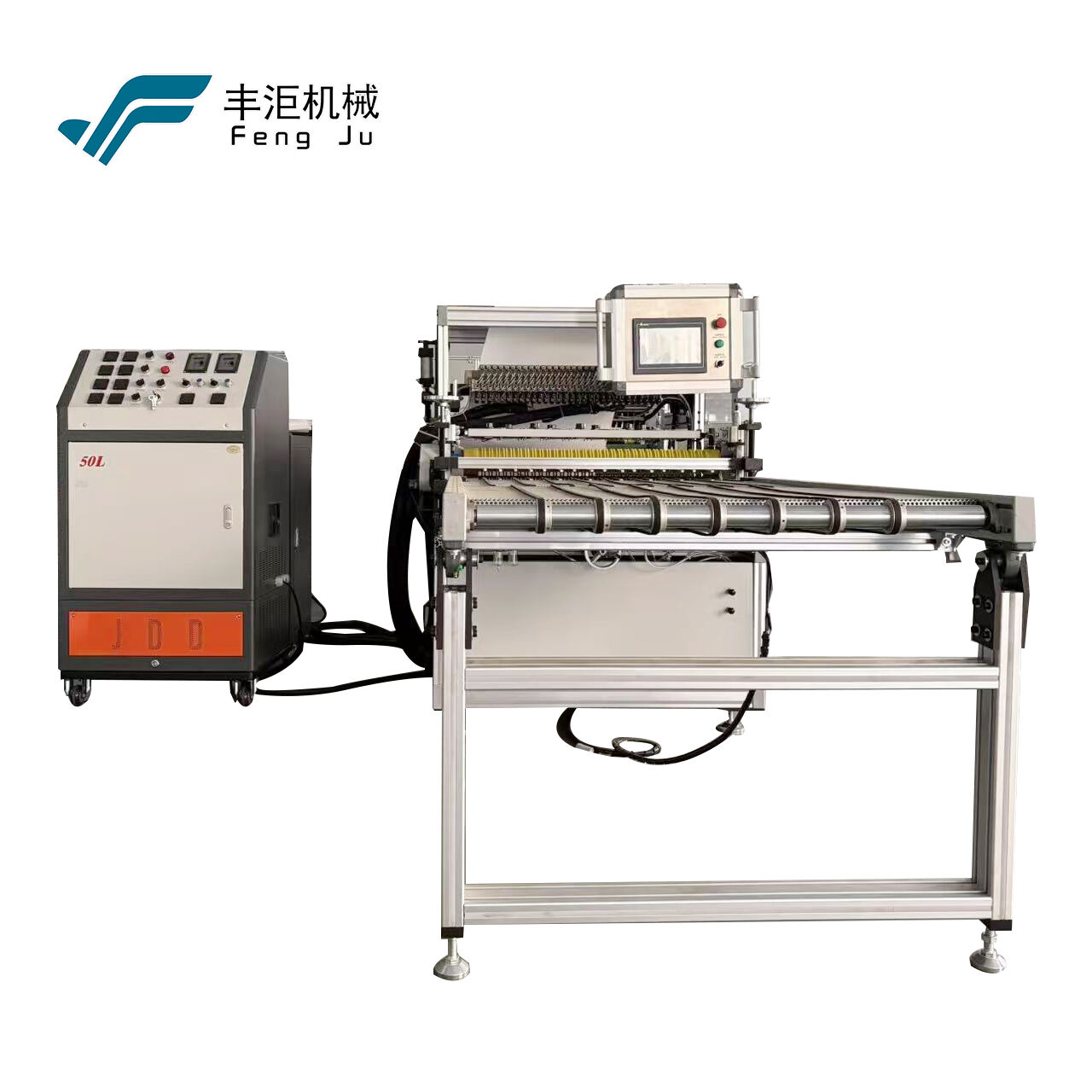

activated carbon filter pleating machine

The activated carbon filter pleating machine represents a sophisticated piece of industrial equipment designed to efficiently manufacture pleated activated carbon filters. This advanced machinery combines precision engineering with automated processes to create uniform, high-quality filter elements. The machine operates by feeding activated carbon filter media through a carefully calibrated system that creates consistent pleats, maximizing the filtration surface area while maintaining structural integrity. Its core functions include material feeding, precise pleat formation, and automatic spacing control, all managed through an intuitive digital control interface. The machine accommodates various filter media widths and can be adjusted for different pleat heights and depths, offering versatility in production capabilities. The technology incorporates real-time monitoring systems that ensure pleat accuracy and maintain consistent quality throughout the production run. Notable features include automated tension control, precision scoring mechanisms, and adjustable pleat pitch settings that allow for customization based on specific filtration requirements. This equipment is particularly valuable in industrial air filtration, automotive filter production, and commercial HVAC systems manufacturing, where consistent quality and high production efficiency are essential.