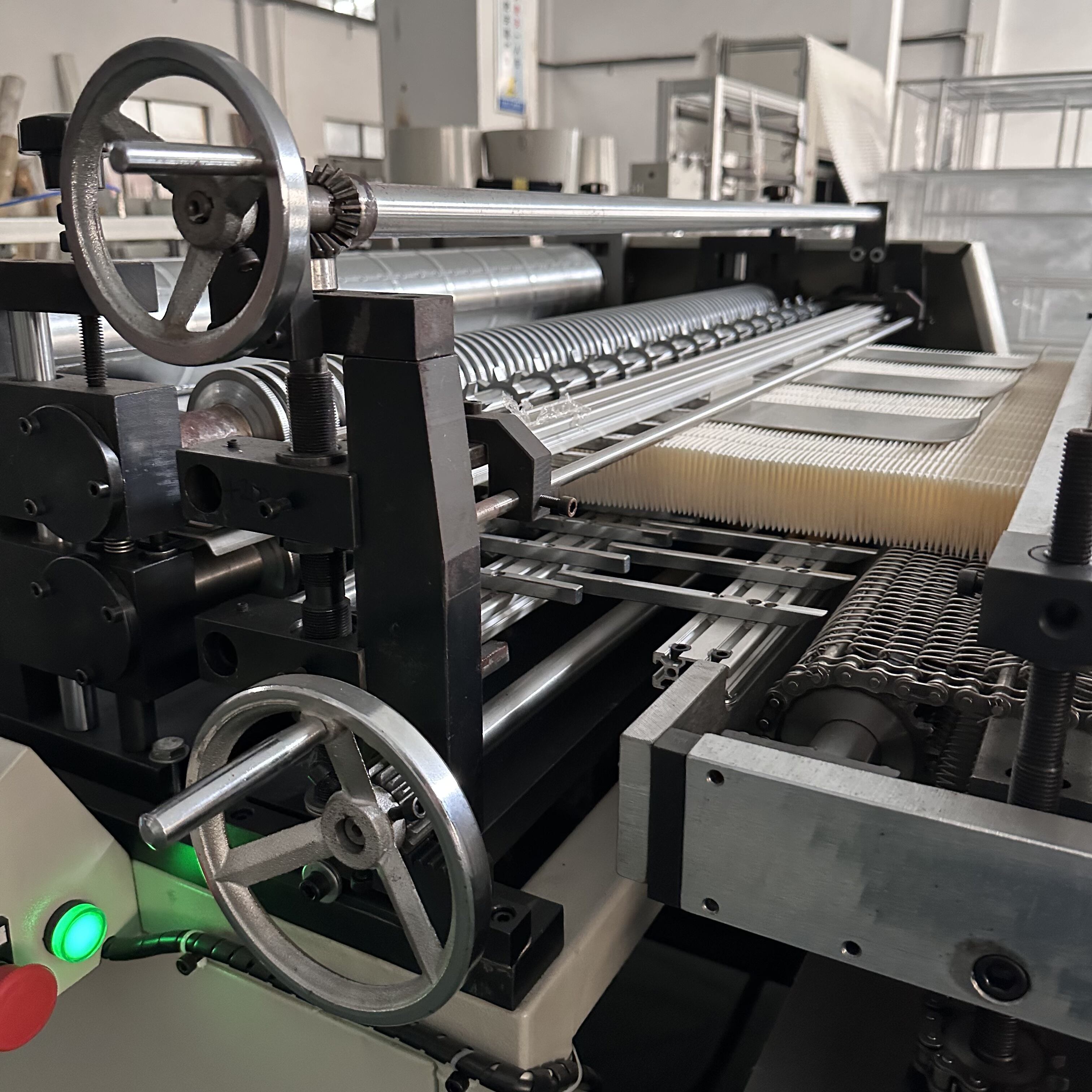

hepa pleating machine with baffle

The HEPA pleating machine with baffle represents a significant advancement in air filtration technology manufacturing. This sophisticated equipment is designed to create precise pleats in HEPA filter media while incorporating baffles for enhanced performance and durability. The machine utilizes advanced servo motor technology to ensure consistent pleat spacing and depth, critical for maintaining optimal filtration efficiency. Its automated system can handle various filter media thicknesses and compositions, making it versatile for different HEPA filter specifications. The integrated baffle insertion mechanism works synchronously with the pleating process, positioning reinforcement materials at precise intervals to maintain pleat stability and prevent collapse under high air pressure conditions. The machine features digital controls for precise adjustment of pleat height, pitch, and spacing, allowing manufacturers to meet diverse customer requirements and industry standards. With production speeds capable of reaching up to 15 meters per minute, it significantly enhances manufacturing efficiency while maintaining exceptional quality standards. The system includes automatic tension control and media alignment systems to ensure uniform pleat formation and prevent material waste. Additionally, its modular design facilitates easy maintenance and quick changeovers between different filter media types.