fabric accordion pleating machine

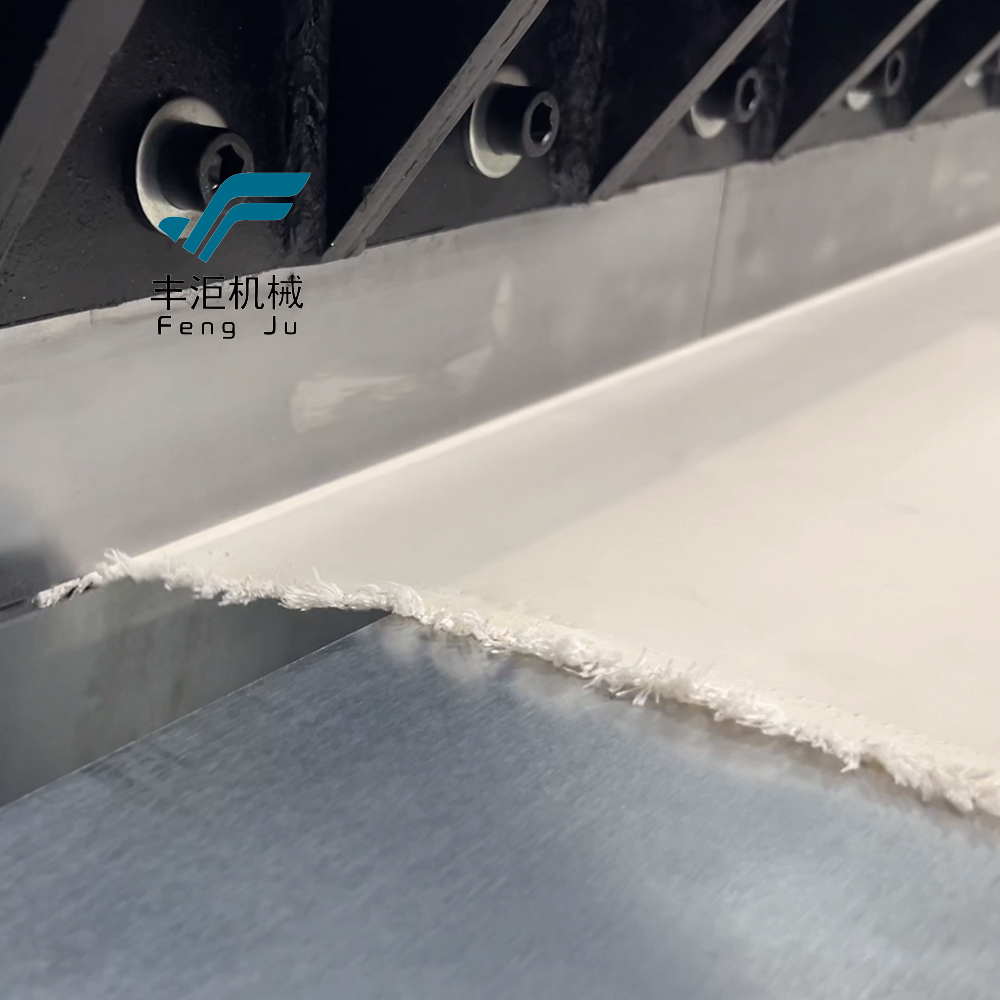

The fabric accordion pleating machine represents a significant advancement in textile processing technology, designed to create precise and consistent accordion-style pleats in various fabric materials. This sophisticated equipment operates through a combination of heat setting and mechanical folding mechanisms, enabling the production of uniform pleats ranging from fine to wide configurations. The machine features adjustable temperature controls, variable speed settings, and customizable pleat width options, making it versatile enough to handle different fabric types and weights. At its core, the system employs a series of heated plates that work in conjunction with precision-engineered folding mechanisms to create sharp, durable pleats. The automated feed system ensures consistent fabric tension throughout the pleating process, while digital controls allow operators to maintain precise settings for temperature, speed, and pleat dimensions. Additionally, the machine incorporates safety features such as emergency stop buttons and temperature monitoring systems to protect both operators and materials. Its applications span across fashion manufacturing, home textiles, and industrial fabric processing, making it an essential tool for businesses requiring high-quality pleated materials.