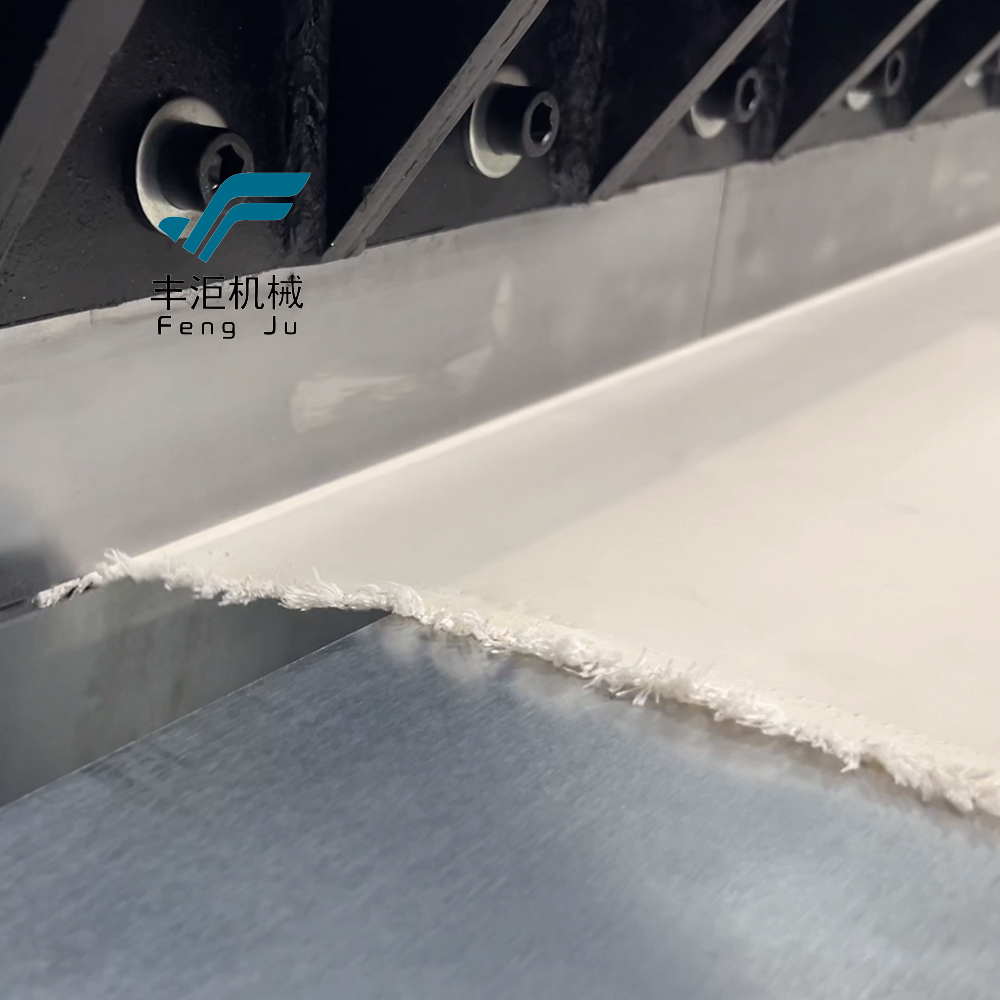

pleats fabric machine

The pleats fabric machine represents a significant advancement in textile manufacturing technology, offering precision and efficiency in creating various pleated fabric designs. This sophisticated equipment utilizes a combination of heat setting, mechanical pressure, and precision control systems to produce consistent, high-quality pleated materials. The machine's core functionality includes temperature-controlled pressing plates, adjustable pleat depth settings, and automated fabric feeding mechanisms that ensure uniform pleat formation across different fabric types. Operating at speeds of up to 20 meters per minute, it can handle various fabric compositions, from lightweight polyester to heavier cotton blends. The machine features digital controls that allow operators to program and store multiple pleat patterns, making pattern switching quick and efficient. Its advanced heating system maintains precise temperatures throughout the pleating process, crucial for achieving permanent pleats that retain their shape after washing. The machine's versatility extends to creating different pleat styles, including knife pleats, box pleats, and accordion pleats, making it invaluable for fashion manufacturers, home textile producers, and industrial fabric processors.