fabric pleating machine textile

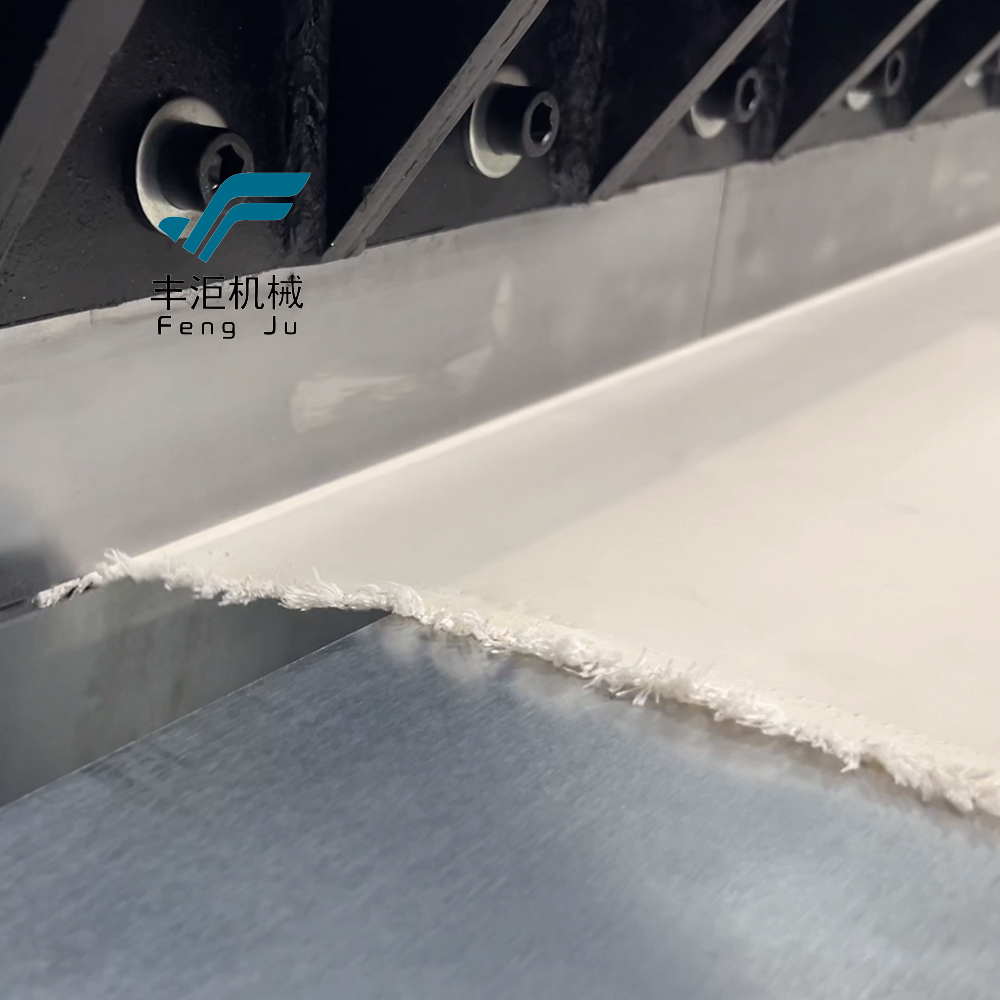

The fabric pleating machine textile represents a sophisticated piece of manufacturing equipment designed to create precise, uniform pleats in various fabric materials. This advanced machinery combines mechanical precision with customizable settings to produce consistent pleating patterns that meet diverse industrial and fashion requirements. The machine operates through a system of heated plates and precise pressure mechanisms, allowing for the creation of different pleat styles, including knife pleats, box pleats, and accordion pleats. Its technological features include digital temperature control systems, adjustable pressure settings, and programmable pleat depth parameters. The machine can process a wide range of fabric types, from lightweight materials like chiffon to heavier textiles such as wool blends, making it versatile for multiple applications. Modern fabric pleating machines often incorporate automated feeding systems and can handle continuous production runs, significantly improving efficiency in textile manufacturing. These machines are essential in fashion manufacturing, home decor production, and industrial textile processing, offering the capability to create decorative elements and functional pleating patterns that enhance both the aesthetic and practical aspects of finished textile products.