fabric pleating machine price

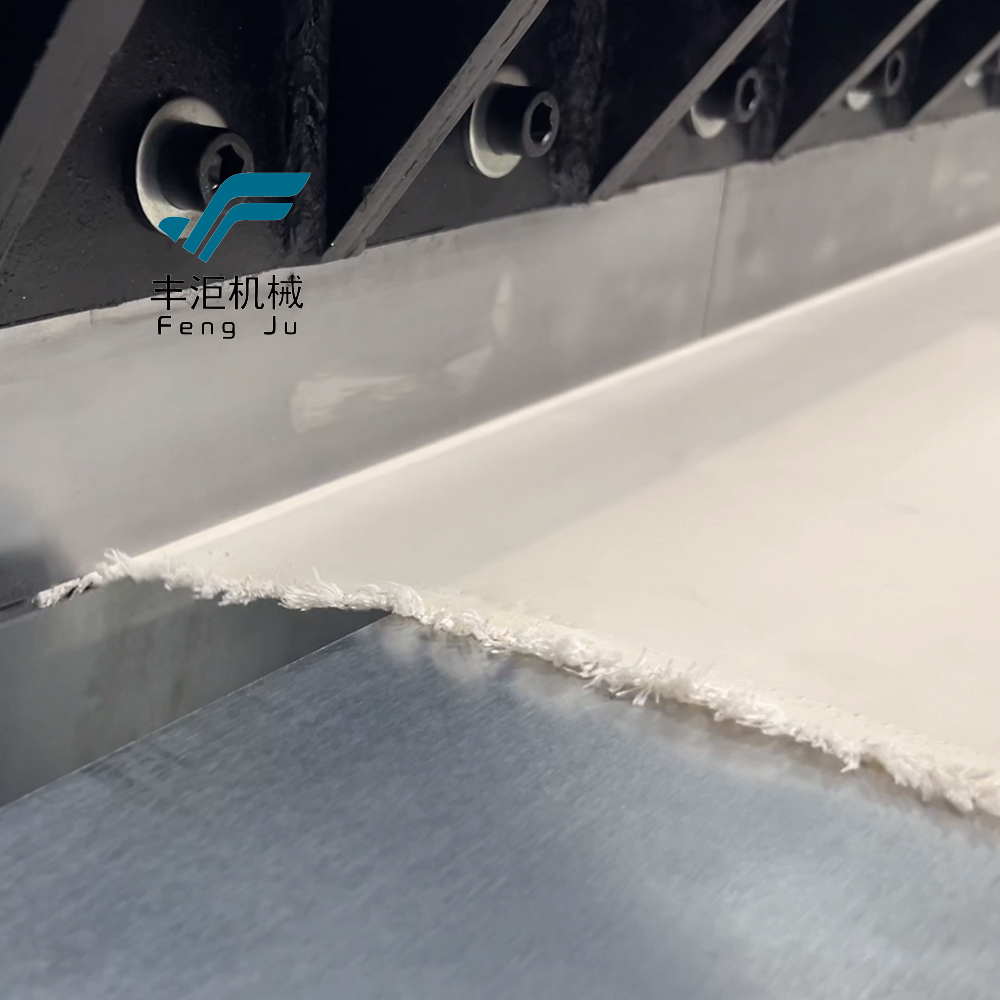

The fabric pleating machine price reflects a significant investment in advanced textile processing technology. These machines, available across various price points from $5,000 to $50,000, offer sophisticated pleating capabilities for diverse fabric types. The pricing structure typically correlates with the machine's production capacity, automation level, and technical specifications. Entry-level models, suitable for small-scale operations, generally range from $5,000 to $15,000, while industrial-grade machines command higher prices due to their enhanced features and productivity. The price encompasses essential functions including programmable pleat patterns, adjustable pleat depths, and temperature control systems. Most modern units feature digital control panels, automatic fabric feeding mechanisms, and precise heat distribution systems. The investment covers comprehensive pleating solutions for materials ranging from lightweight chiffons to heavy upholstery fabrics. Machines in the mid-range category, priced between $15,000 and $30,000, typically offer additional features such as multiple pleating patterns, higher production speeds, and improved energy efficiency. The price point also reflects the inclusion of safety features, warranty coverage, and after-sales support, ensuring long-term operational reliability and value for businesses.