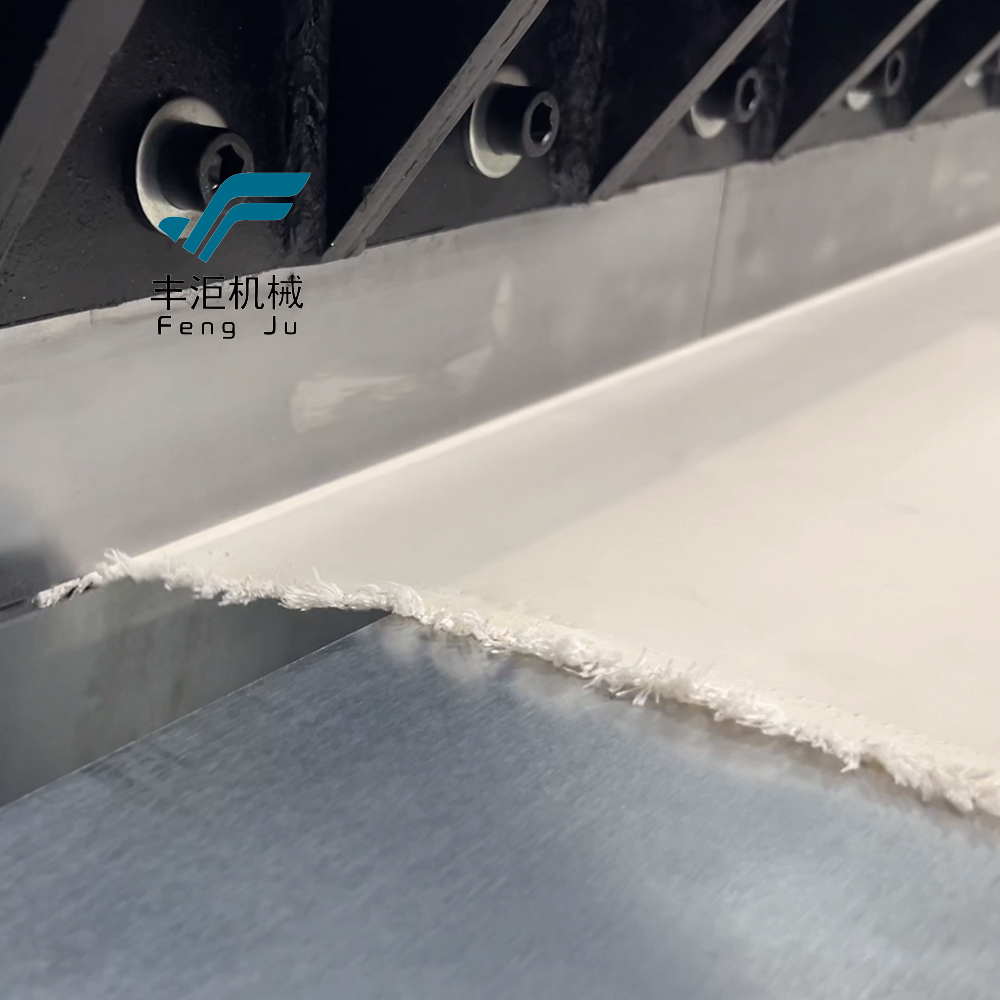

fabric folding pleating machine

The fabric folding pleating machine represents a significant advancement in textile processing technology, offering precision and efficiency in creating consistent pleats across various fabric types. This sophisticated equipment utilizes a combination of heat setting and mechanical folding mechanisms to produce uniform, well-defined pleats that meet exact specifications. The machine features adjustable temperature controls, variable speed settings, and customizable pleat width options, allowing manufacturers to achieve diverse pleating patterns and depths. Its automated feeding system ensures continuous operation while maintaining fabric alignment, significantly reducing manual handling and potential errors. The machine's innovative design incorporates advanced sensors that monitor fabric tension and temperature, ensuring optimal processing conditions throughout the operation. Particularly noteworthy is its versatility in handling different fabric weights and compositions, from lightweight chiffons to heavier materials like wool blends. The computerized control system enables operators to store and recall specific pleating patterns, ensuring consistency across production runs. This technology has found widespread application in fashion manufacturing, home textiles, and industrial fabric processing, where precise pleating is essential for both decorative and functional purposes.