semi-automatic curtain pleating machine

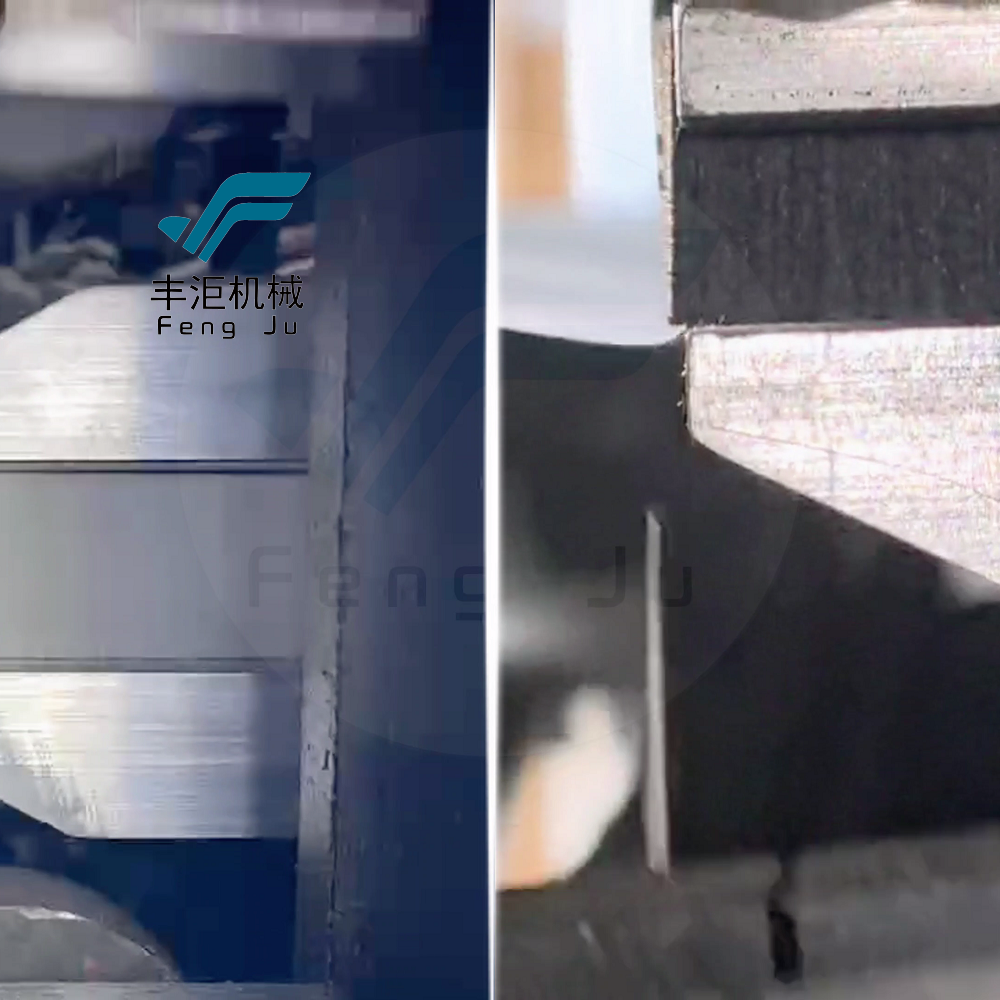

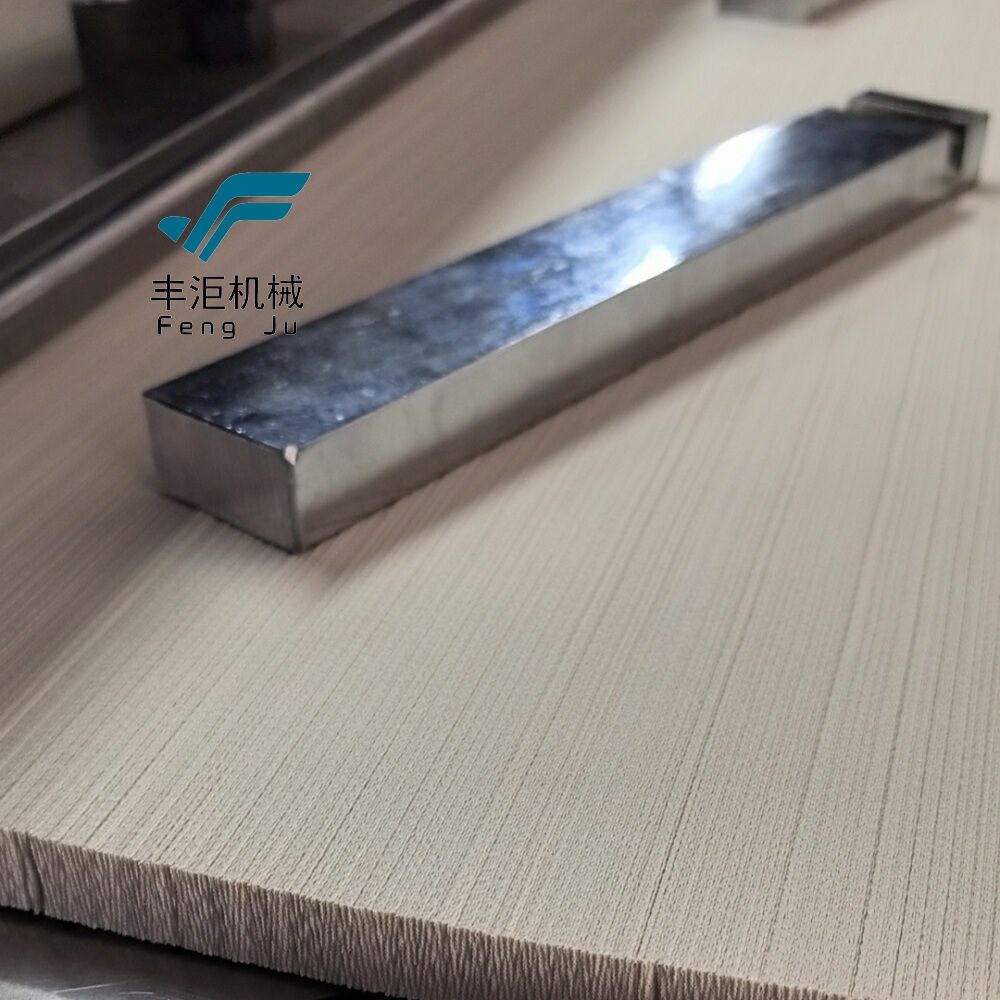

The semi-automatic curtain pleating machine represents a significant advancement in textile processing technology, combining efficiency with precision in curtain manufacturing. This innovative equipment streamlines the pleating process by automatically creating uniform, precise pleats while allowing operators to maintain control over the final product quality. The machine features adjustable pleat depth settings ranging from 2.5 to 4 inches, enabling versatility in design options. Its robust construction includes a stainless steel work surface and pneumatic pressing mechanism, ensuring durability and consistent performance. The machine can process various fabric types, from lightweight sheers to heavy drapes, with equal effectiveness. Operating at speeds of up to 20 pleats per minute, it significantly reduces production time compared to manual pleating methods. The integrated measuring system ensures precise spacing between pleats, while the adjustable pressure control allows for customization based on fabric thickness. Safety features include emergency stop buttons and finger guards, making it suitable for both experienced operators and trainees. The machine's compact design requires minimal floor space, making it ideal for workshops of any size.