office curtain pleating machine

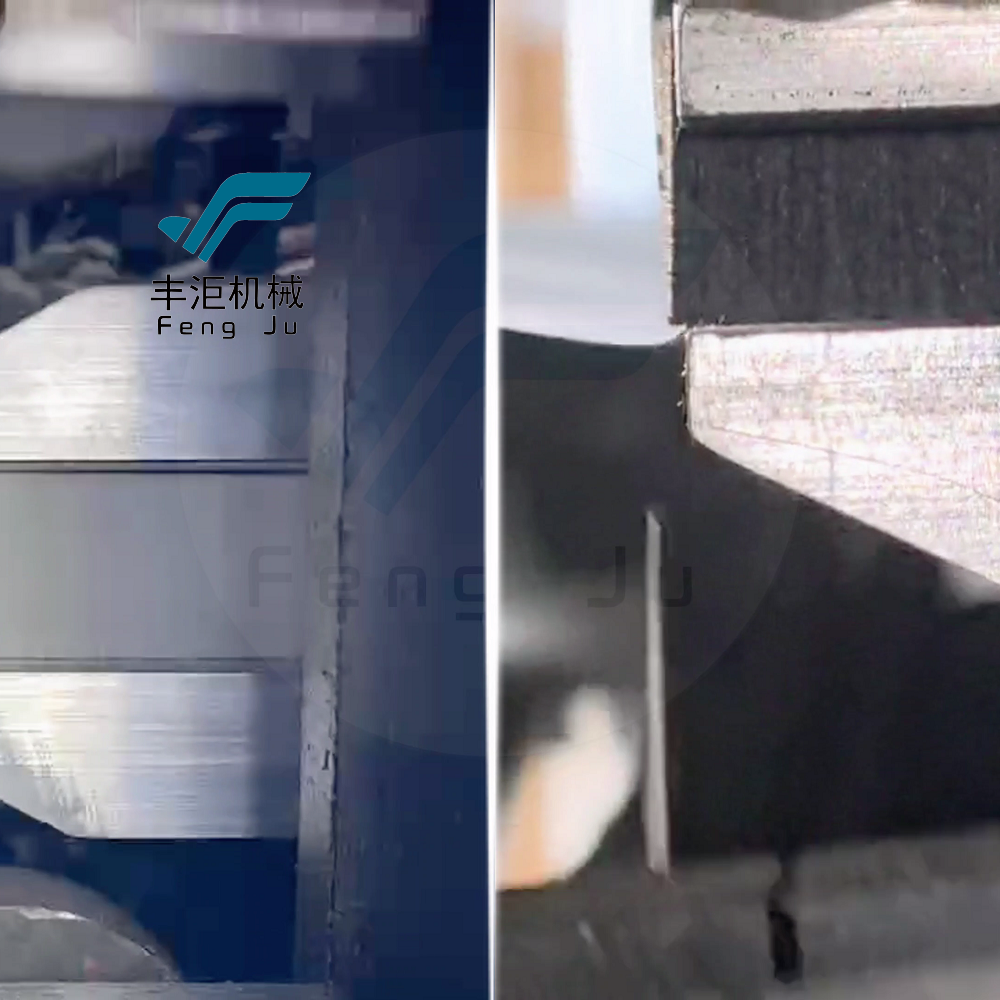

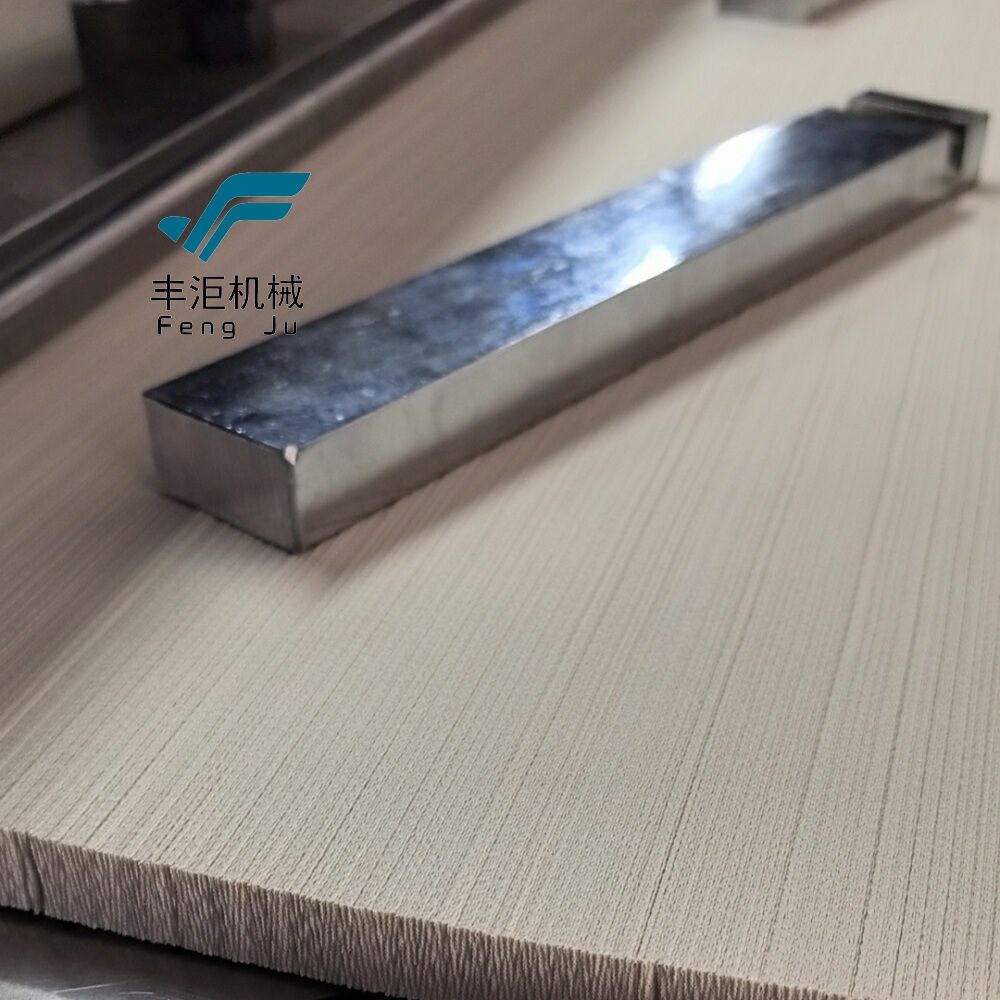

The office curtain pleating machine represents a significant advancement in automated textile processing technology. This sophisticated equipment streamlines the creation of professionally pleated curtains through a combination of precision engineering and innovative design. The machine features an advanced feeding system that carefully handles various fabric types, from light sheers to heavy drapes, ensuring consistent pleat formation without damaging the material. Its computerized control panel allows operators to program specific pleat patterns, spacing, and depths, offering versatility in design options. The machine incorporates a heating element that sets the pleats permanently, resulting in long-lasting, crisp folds that maintain their shape. With production speeds of up to 20 meters per hour, this machine significantly reduces manual labor while maintaining exceptional quality standards. The automatic fabric alignment system ensures straight, even pleats throughout the entire curtain length, eliminating human error and inconsistencies. Additionally, the machine features built-in safety mechanisms, including emergency stops and fabric tension controls, protecting both operators and materials during the pleating process.