industrial curtain pleating machine

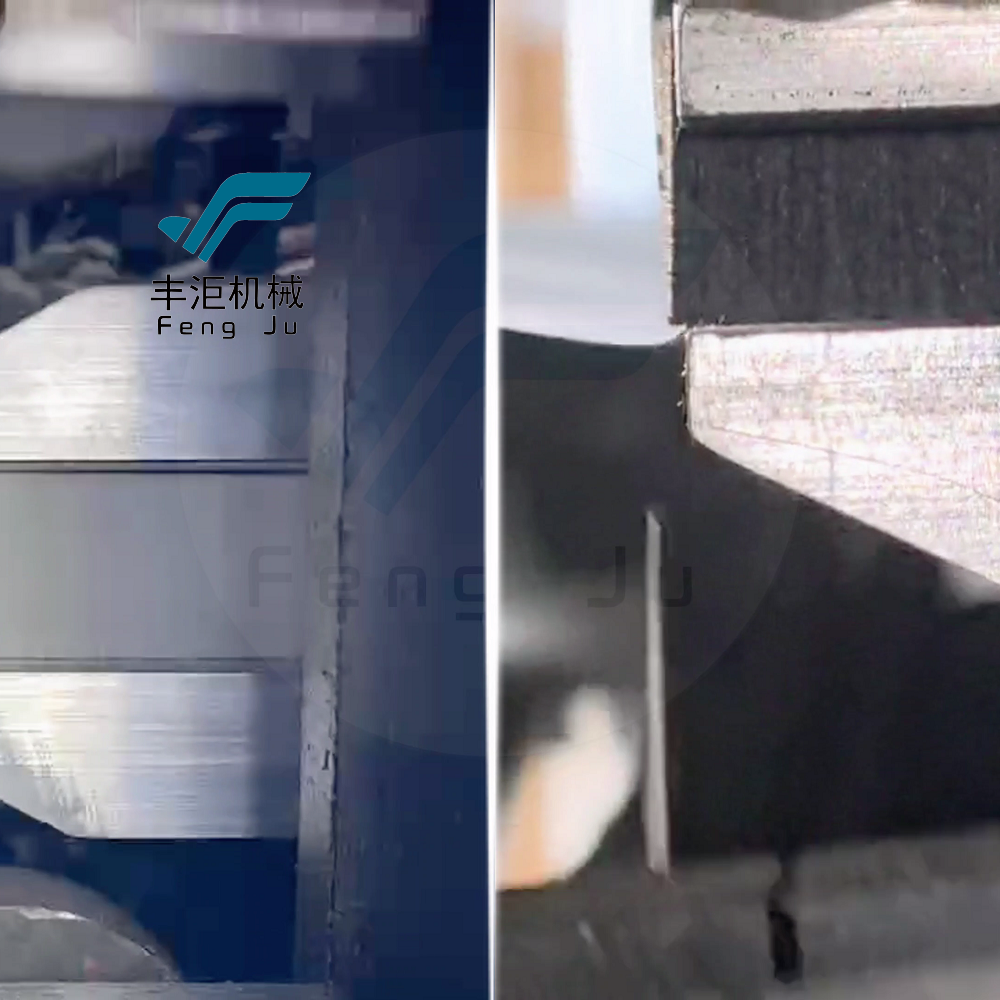

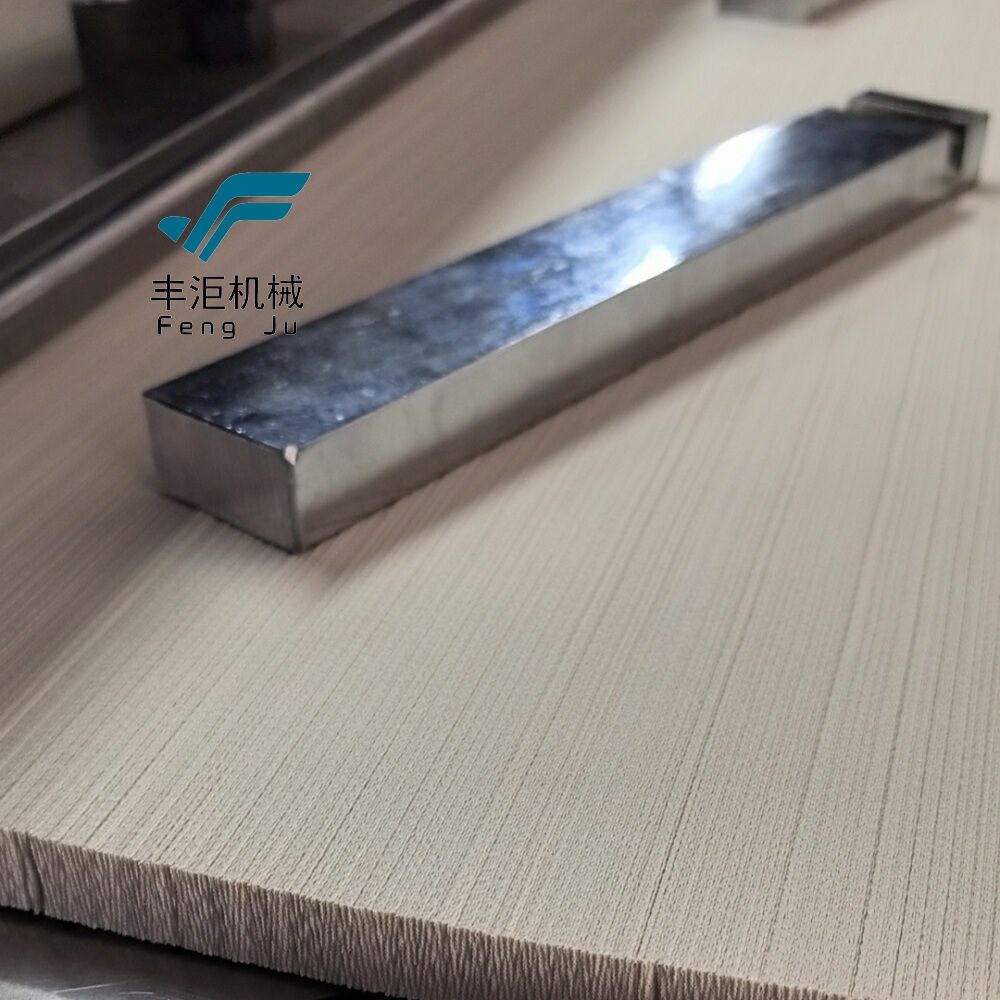

The industrial curtain pleating machine represents a significant advancement in textile manufacturing technology, designed to create precise and uniform pleats in various fabric materials. This sophisticated equipment combines mechanical precision with automated controls to produce consistent pleating patterns across large volumes of curtain fabric. The machine features adjustable pleating mechanisms that can accommodate different fabric weights and textures, from lightweight sheers to heavy drapes. Its automated feed system ensures smooth fabric handling while maintaining precise pleat measurements and spacing. The machine incorporates advanced tension control systems to prevent fabric distortion and guarantee uniform pleating results. Operating at industrial speeds, it can process hundreds of meters of fabric per hour while maintaining exceptional quality standards. The system includes programmable controls that allow operators to store and recall specific pleating patterns, making it efficient for both standardized production runs and custom orders. Safety features include emergency stop mechanisms and fabric tension sensors to prevent material damage. The machine's versatility extends to various pleating styles, including box pleats, pinch pleats, and accordion pleats, making it an essential tool for curtain manufacturers, interior design companies, and textile processing facilities.