blackout curtain pleating machine

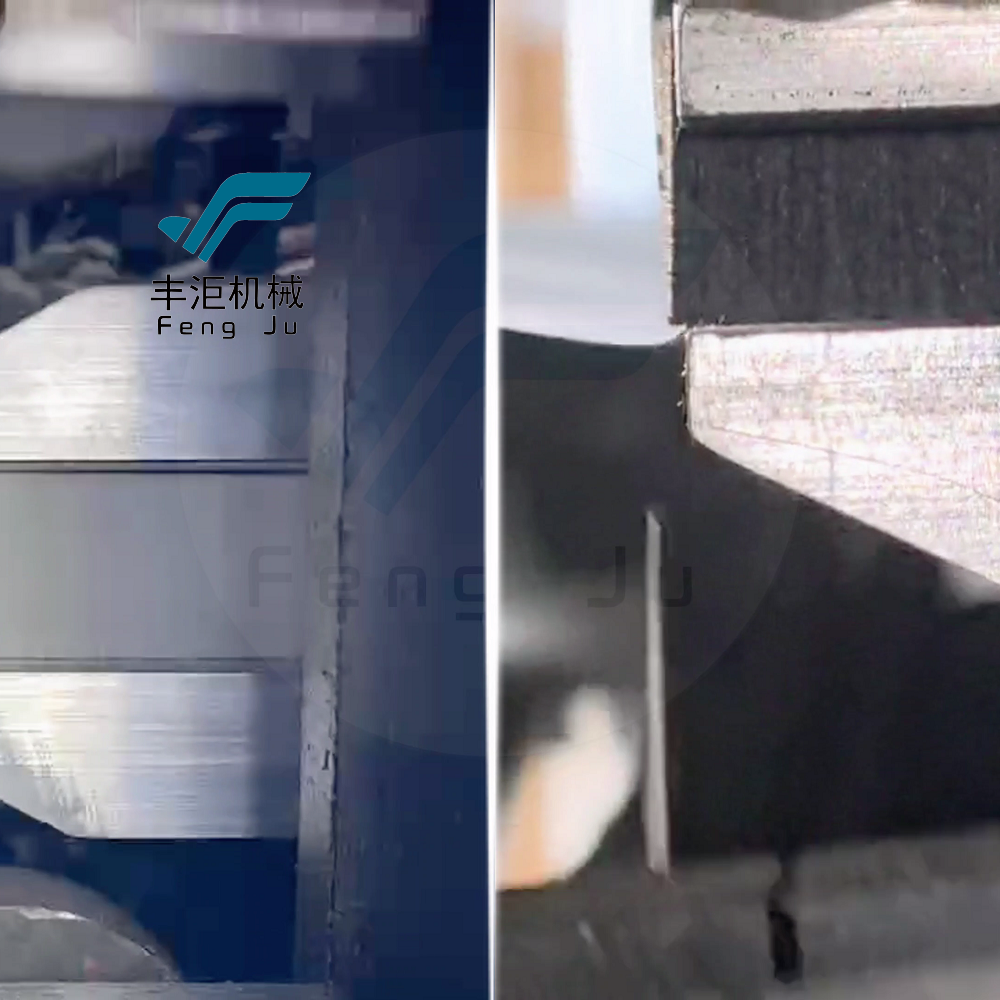

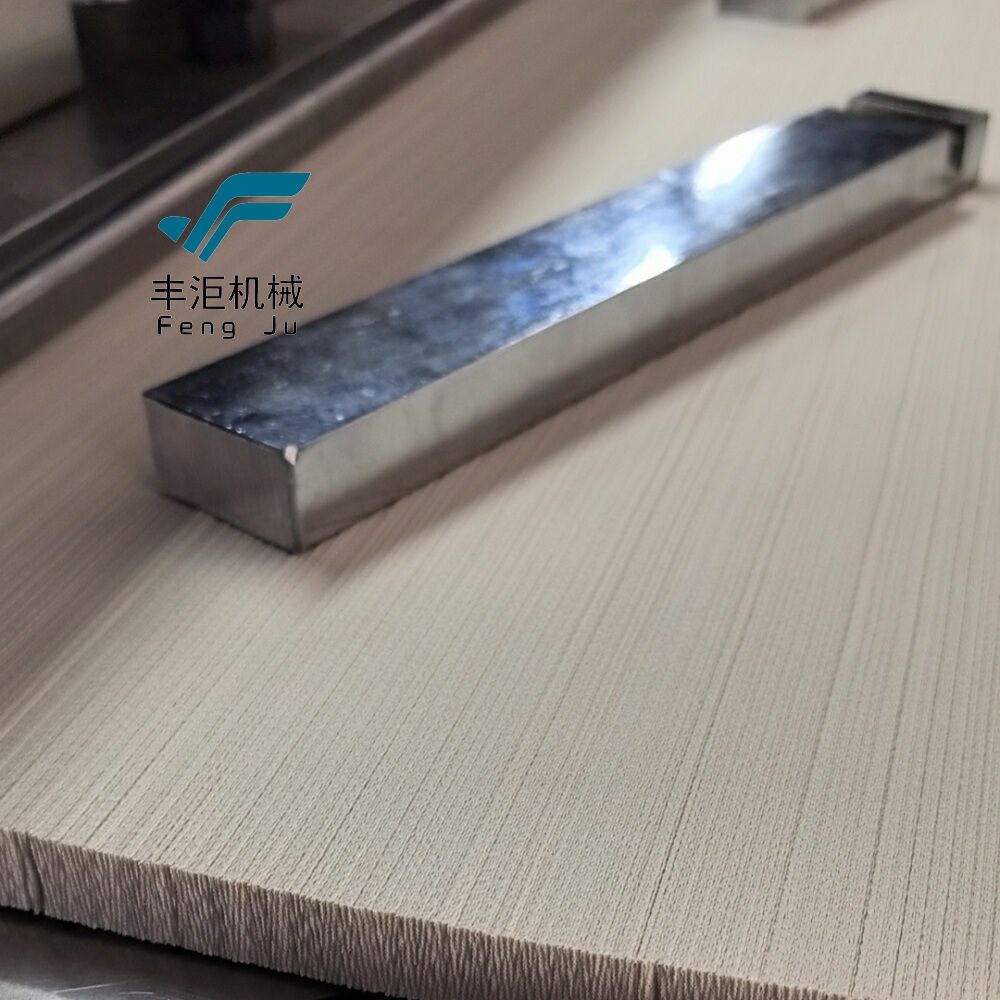

The blackout curtain pleating machine represents a significant advancement in automated textile processing technology. This sophisticated equipment streamlines the production of pleated blackout curtains through a precise, mechanized process. The machine incorporates advanced folding mechanisms that create uniform, durable pleats in blackout fabric while maintaining consistent spacing and depth. Its computerized control system enables operators to program specific pleat patterns, sizes, and spacing requirements, ensuring remarkable consistency across production runs. The machine handles various fabric weights and thicknesses, making it versatile for different types of blackout materials. Its high-speed operation can process multiple curtain panels simultaneously, significantly increasing production efficiency. The system includes automatic fabric feeding and alignment mechanisms, reducing manual handling and potential human error. Safety features such as emergency stops and protective guards ensure operator safety while maintaining optimal production flow. The machine's precision engineering extends to its measurement systems, which maintain exact pleat dimensions and ensure symmetrical patterns throughout the fabric length. This technology has revolutionized blackout curtain manufacturing by combining speed, precision, and reliability in a single automated solution.