polyester curtain pleating machine

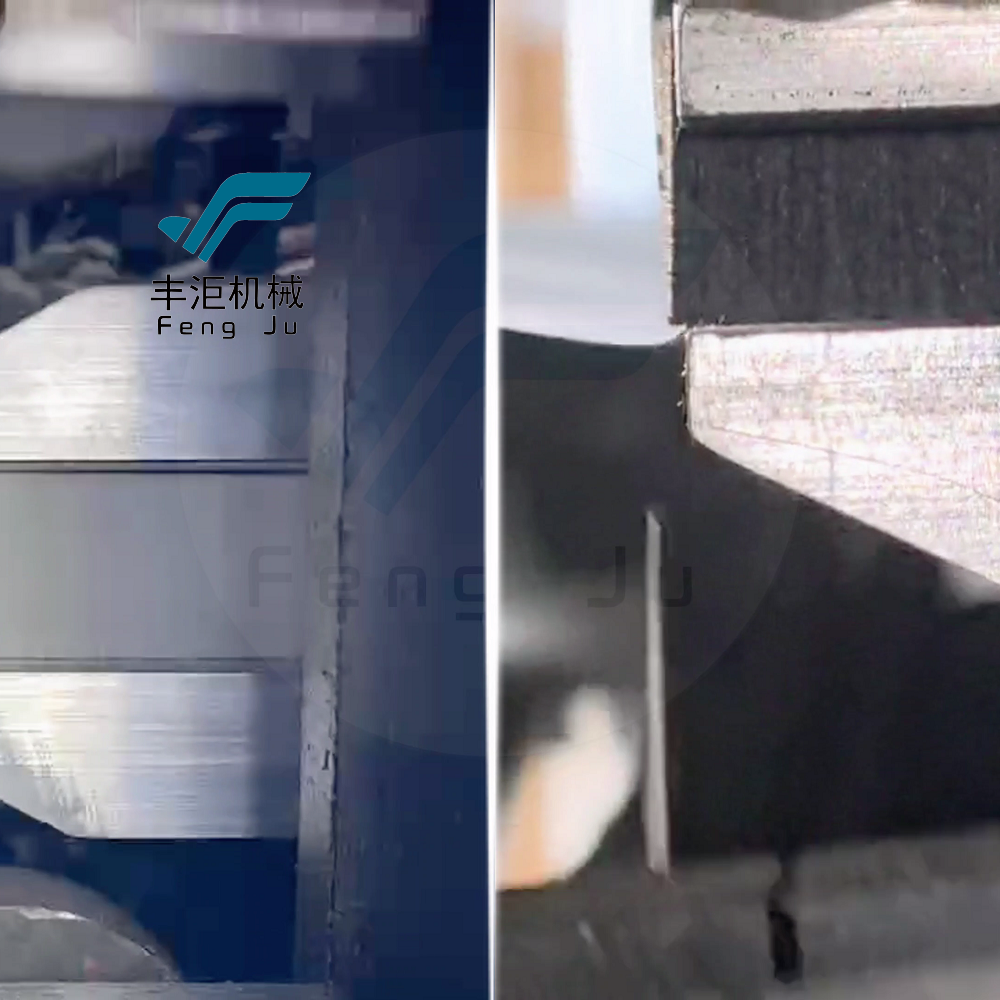

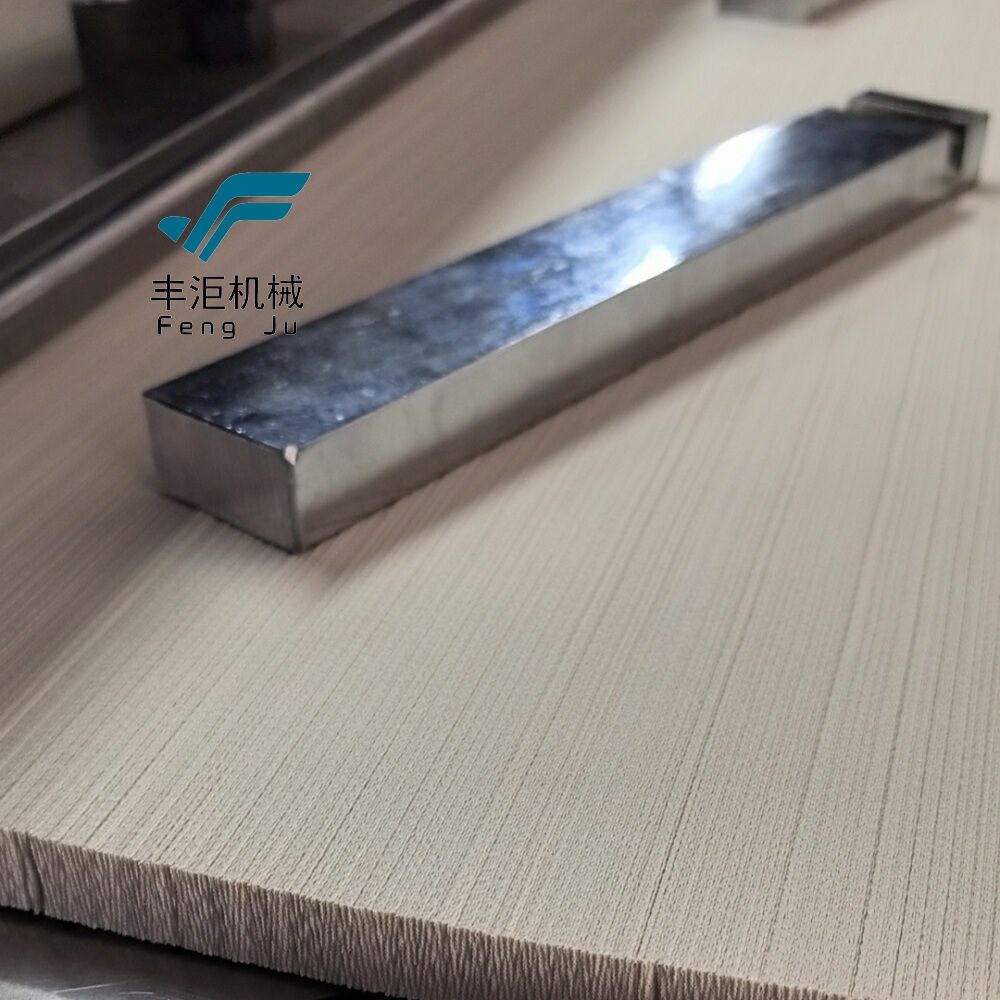

The polyester curtain pleating machine represents a significant advancement in textile processing technology, offering automated and precise pleating solutions for curtain manufacturing. This sophisticated equipment combines mechanical precision with digital control systems to create uniform, professional-grade pleats in polyester curtain materials. The machine features adjustable pleating widths ranging from 2.5 to 10 centimeters, accommodating various curtain styles and design requirements. Its innovative heating system maintains consistent temperatures throughout the pleating process, ensuring permanent and durable pleats in polyester fabrics. The machine's automated feeding mechanism handles fabric widths up to 3 meters, while its programmable control panel allows operators to store and recall multiple pleating patterns. Advanced safety features include emergency stop buttons, overheating protection, and fabric tension sensors. The machine's robust construction, typically featuring stainless steel components, ensures longevity and reliable performance in high-volume production environments. Its precision engineering enables the creation of various pleat styles, including box pleats, pinch pleats, and wave patterns, meeting diverse market demands.