curtain pleating machine

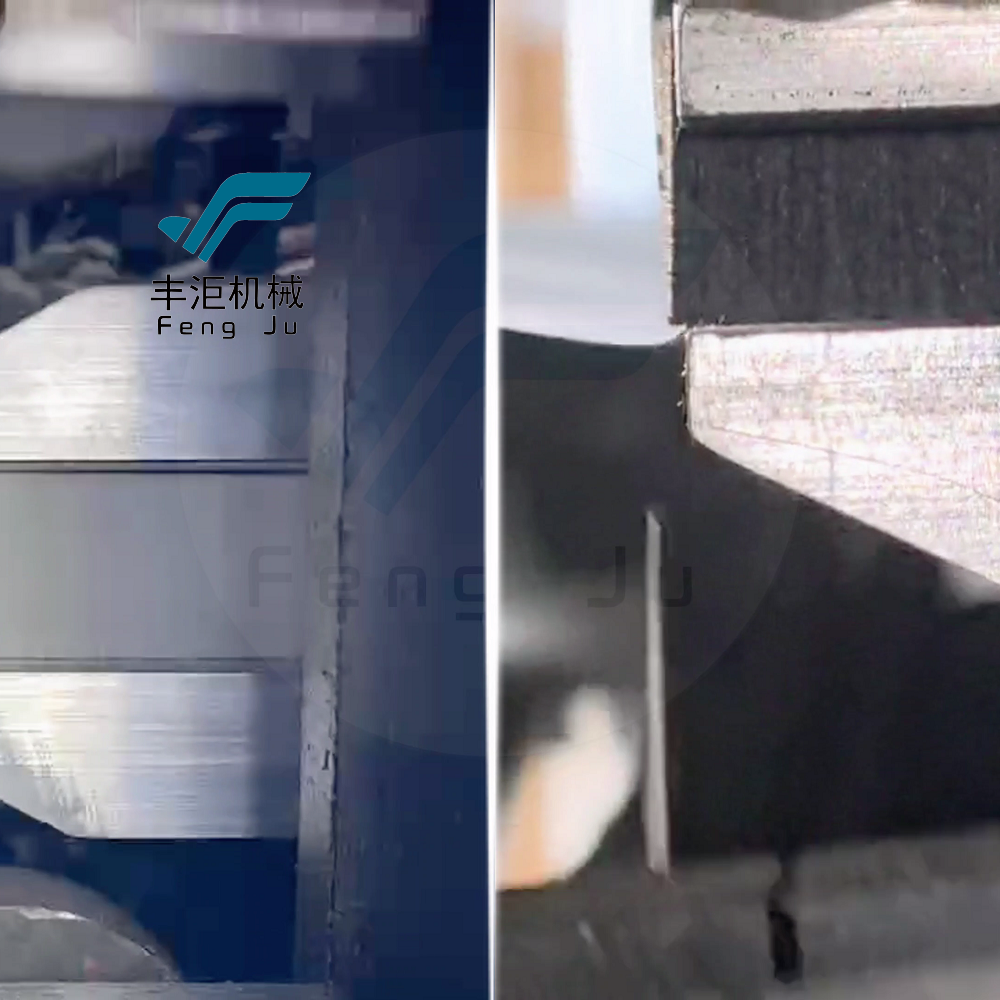

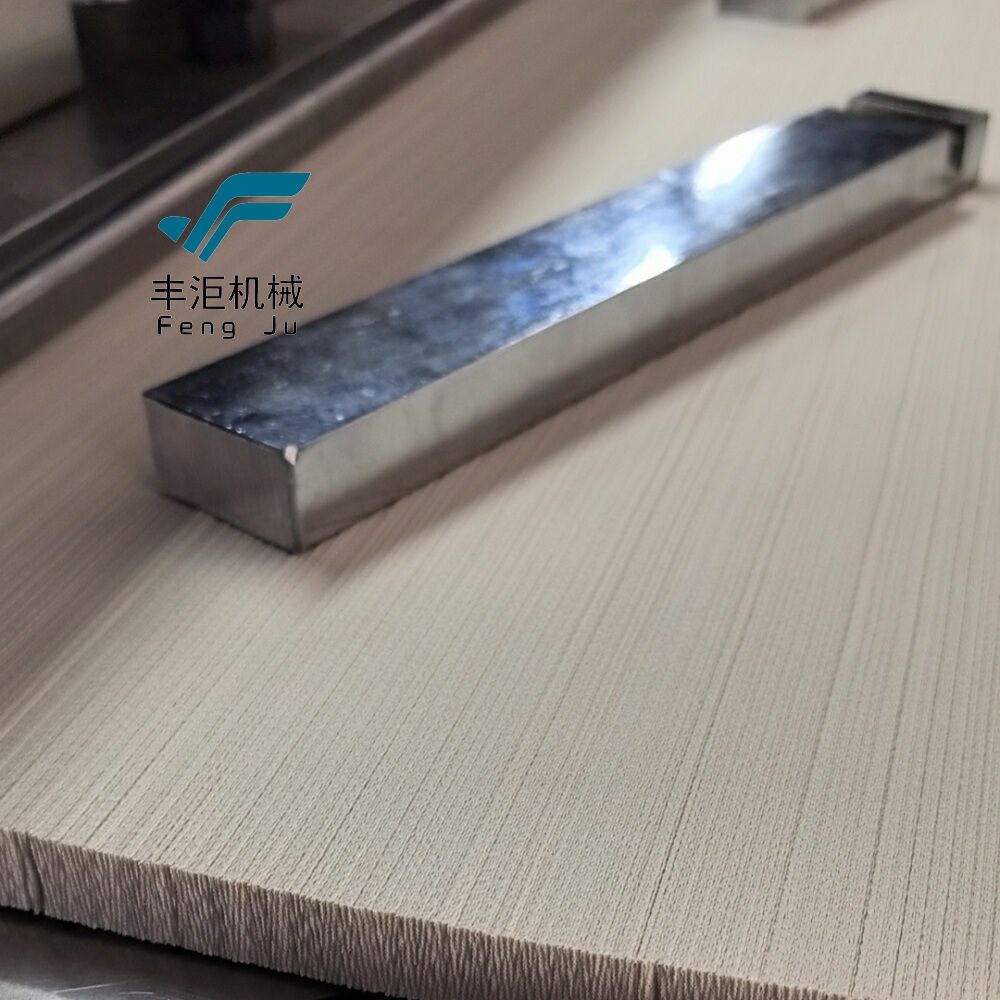

The curtain pleating machine represents a sophisticated advancement in textile manufacturing technology, designed to automate and streamline the process of creating precise, uniform pleats in curtain fabrics. This innovative equipment combines mechanical precision with digital control systems to produce consistently high quality pleated curtains. The machine operates through a series of carefully calibrated mechanisms that grip, fold, and heat-set fabric according to predetermined patterns and measurements. It can handle various fabric types and weights, from lightweight sheers to heavy drapes, making it versatile for different curtain styles. The machine's core functionality includes automated fabric feeding, precise pleat measurement and formation, and thermal setting capabilities to ensure pleat permanence. Advanced models feature programmable settings for different pleat styles, including pinch pleats, box pleats, and goblet pleats, allowing manufacturers to easily switch between various designs. The system incorporates safety features and quality control mechanisms to prevent fabric damage and ensure consistent results. With production speeds significantly higher than manual pleating methods, these machines have become essential in modern curtain manufacturing facilities, capable of processing hundreds of meters of fabric per day while maintaining exceptional quality standards.