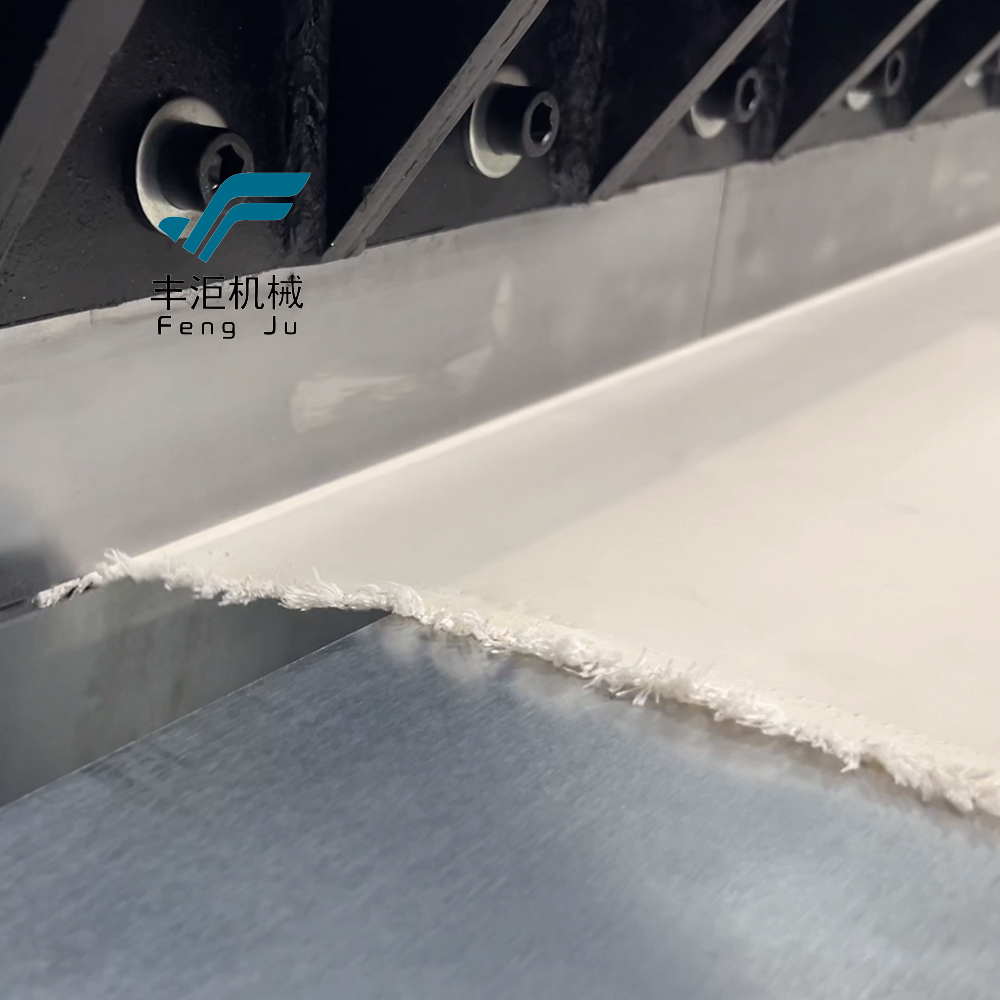

nonwoven fabric pleating machine

The nonwoven fabric pleating machine represents a cutting-edge solution in textile processing technology, designed to create precise and uniform pleats in nonwoven materials. This sophisticated equipment employs advanced mechanical and thermal processes to form consistent pleats across various types of nonwoven fabrics, making it essential for manufacturing filtration materials, face masks, and other pleated products. The machine's core functionality includes a synchronized feeding system that precisely controls material input, a heating element that helps set permanent pleats, and an automated folding mechanism that ensures uniform pleat depth and spacing. Operating at industrial speeds while maintaining precision, these machines can handle different fabric weights and widths, typically processing materials from 20 to 200 GSM. The system incorporates digital controls for precise adjustment of pleat depth, spacing, and processing speed, allowing manufacturers to achieve consistent quality across production runs. Notable features include automatic tension control, temperature monitoring systems, and programmable pleat patterns that enable versatile production capabilities. The machine's robust construction ensures long-term reliability while maintaining efficient production rates of up to 50 meters per minute, depending on the material specifications and pleat requirements.