mosquito net pleating machine supplier

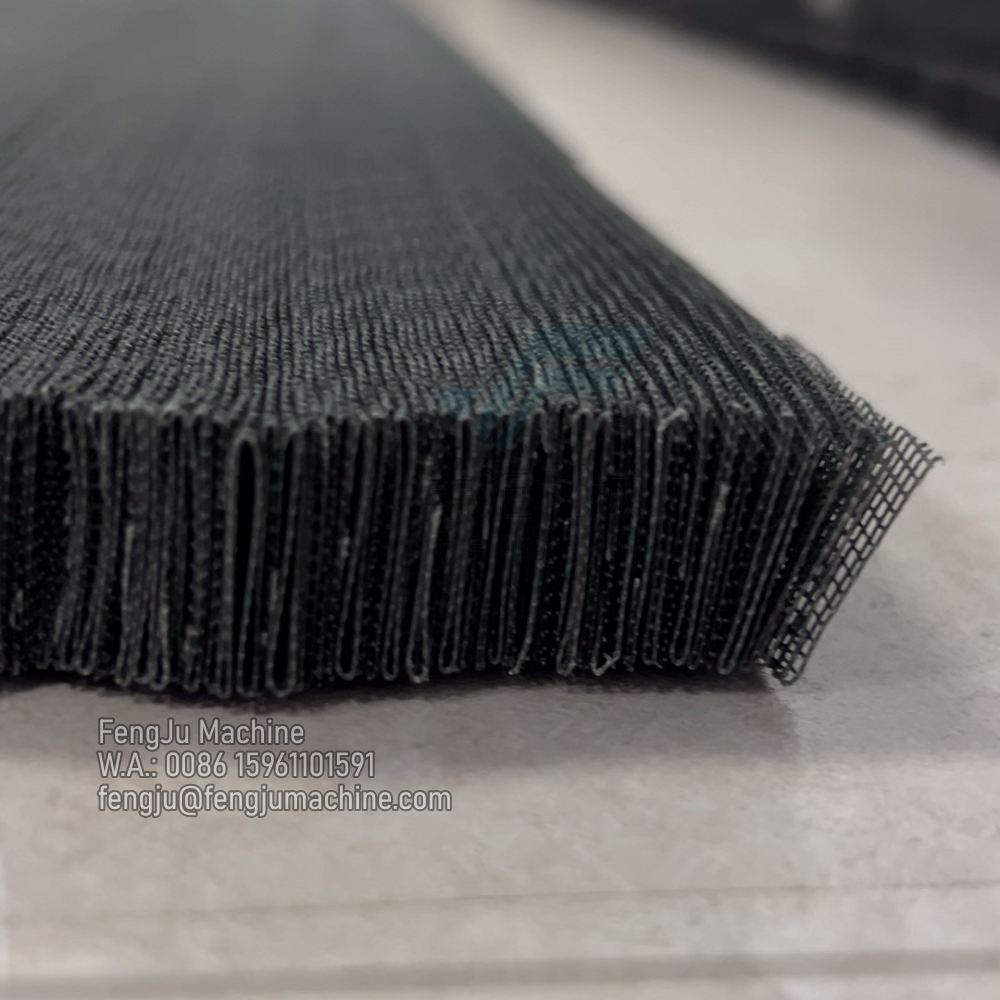

A mosquito net pleating machine supplier stands at the forefront of innovative textile manufacturing technology, offering state-of-the-art equipment designed to streamline the production of pleated mosquito nets. These sophisticated machines incorporate precision engineering to create uniform, durable pleats in mosquito netting material, ensuring consistent quality and high production efficiency. The supplier provides comprehensive solutions that include automated feeding systems, precise pleating mechanisms, and advanced temperature control units for optimal pleat setting. These machines can handle various mesh materials and sizes, with production speeds reaching up to 100 meters per hour. The technology employed ensures exact pleat depths and spacing, crucial for the proper functionality of finished mosquito nets. The supplier's equipment features user-friendly interfaces, digital controls for precise adjustments, and safety mechanisms that protect both operators and materials. Additionally, they offer customization options to meet specific manufacturing requirements, including adjustable pleat sizes, variable speed controls, and different heating element configurations for various fabric types.