pleated mosquito net making machine factory

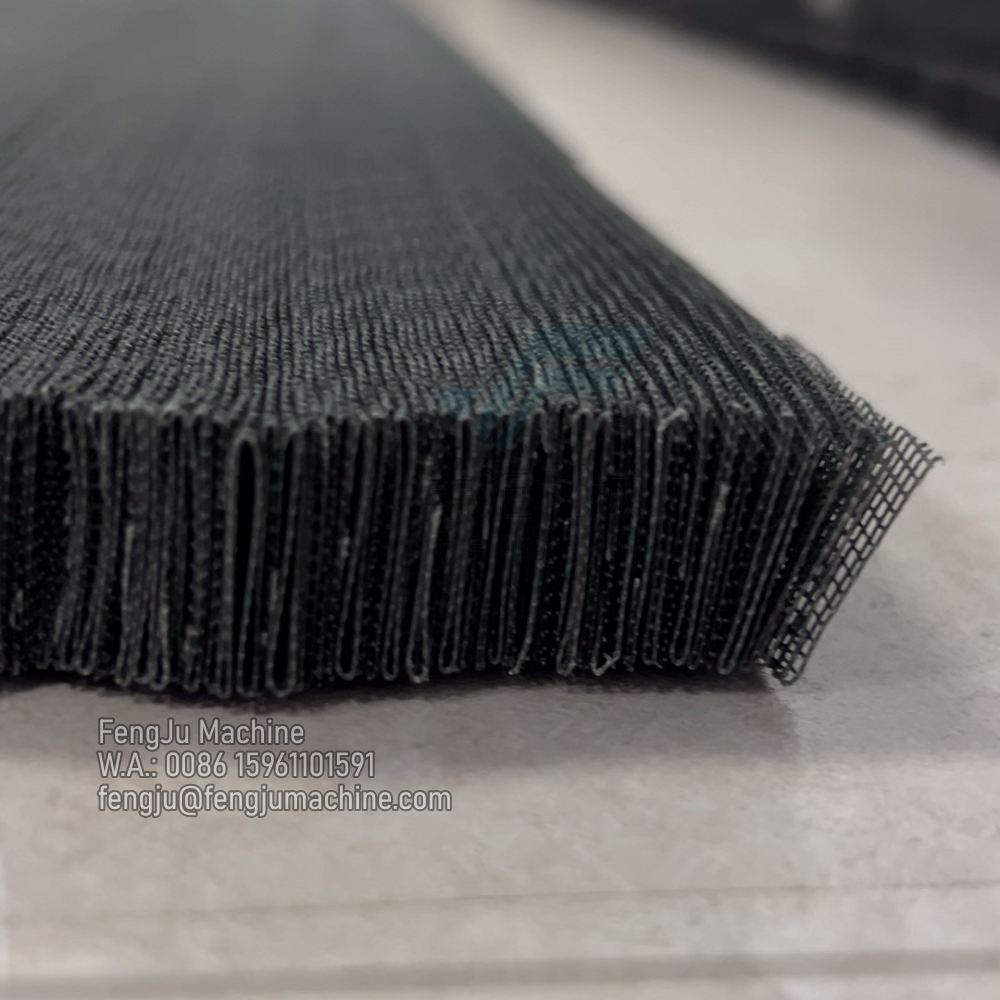

The pleated mosquito net making machine factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality pleated insect screens. This advanced facility incorporates cutting-edge automation technology to ensure precise folding and pleating of mesh materials. The factory's production line features sophisticated measuring systems, automated cutting mechanisms, and precision pleating units that work in perfect synchronization. The facility's core capabilities include customizable pleating patterns, high-speed production rates of up to 500 meters per hour, and integrated quality control systems that monitor mesh tension and pleat uniformity. The manufacturing process employs thermal setting technology to ensure pleat durability and shape retention, while specialized coating stations apply anti-UV and weather-resistant treatments. The factory's modular design allows for flexible production configurations, accommodating various mesh materials and pleat sizes. Advanced sensors and digital controls maintain consistent product quality, while the automated packaging system ensures careful handling of finished products. The facility also features environmentally controlled production areas to maintain optimal manufacturing conditions and prevent contamination.