china pleated mosquito net making machine

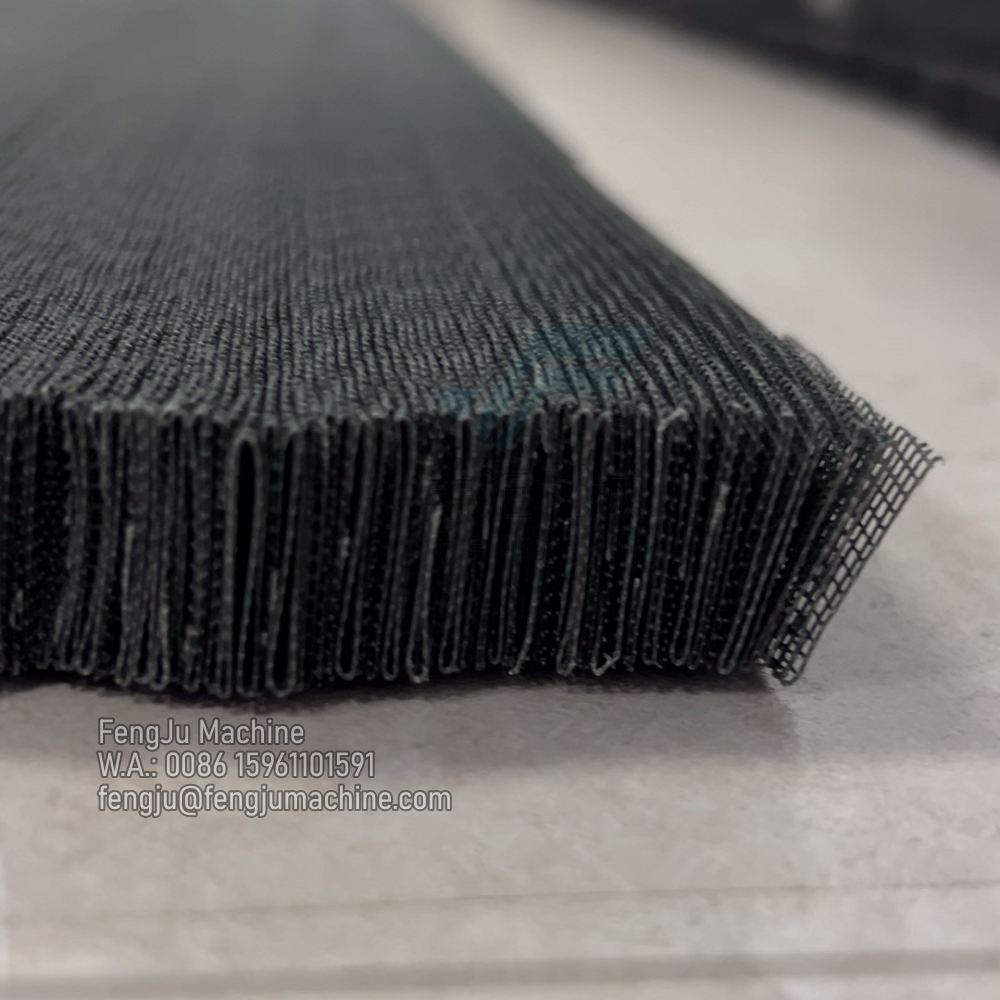

The China Pleated Mosquito Net Making Machine represents a cutting-edge solution in the mosquito net manufacturing industry. This advanced equipment specializes in producing high-quality pleated mesh screens with precise folding patterns and consistent dimensions. The machine utilizes state-of-the-art pleating technology to create durable, uniformly folded mosquito nets that can be easily installed and operated. It features an automated production line capable of handling various mesh materials, including fiberglass and polyester, while maintaining exceptional fold accuracy and product quality. The machine's intelligent control system ensures precise pleating angles and spacing, resulting in professional-grade mosquito nets suitable for residential and commercial applications. With adjustable speed settings and multiple width options, this equipment can accommodate different production requirements and specifications. The machine incorporates thermal stabilization technology to ensure the pleats remain permanent and maintain their shape throughout the product's lifecycle. Additionally, it includes quality control mechanisms that monitor the pleating process in real-time, minimizing material waste and maintaining consistent output quality.