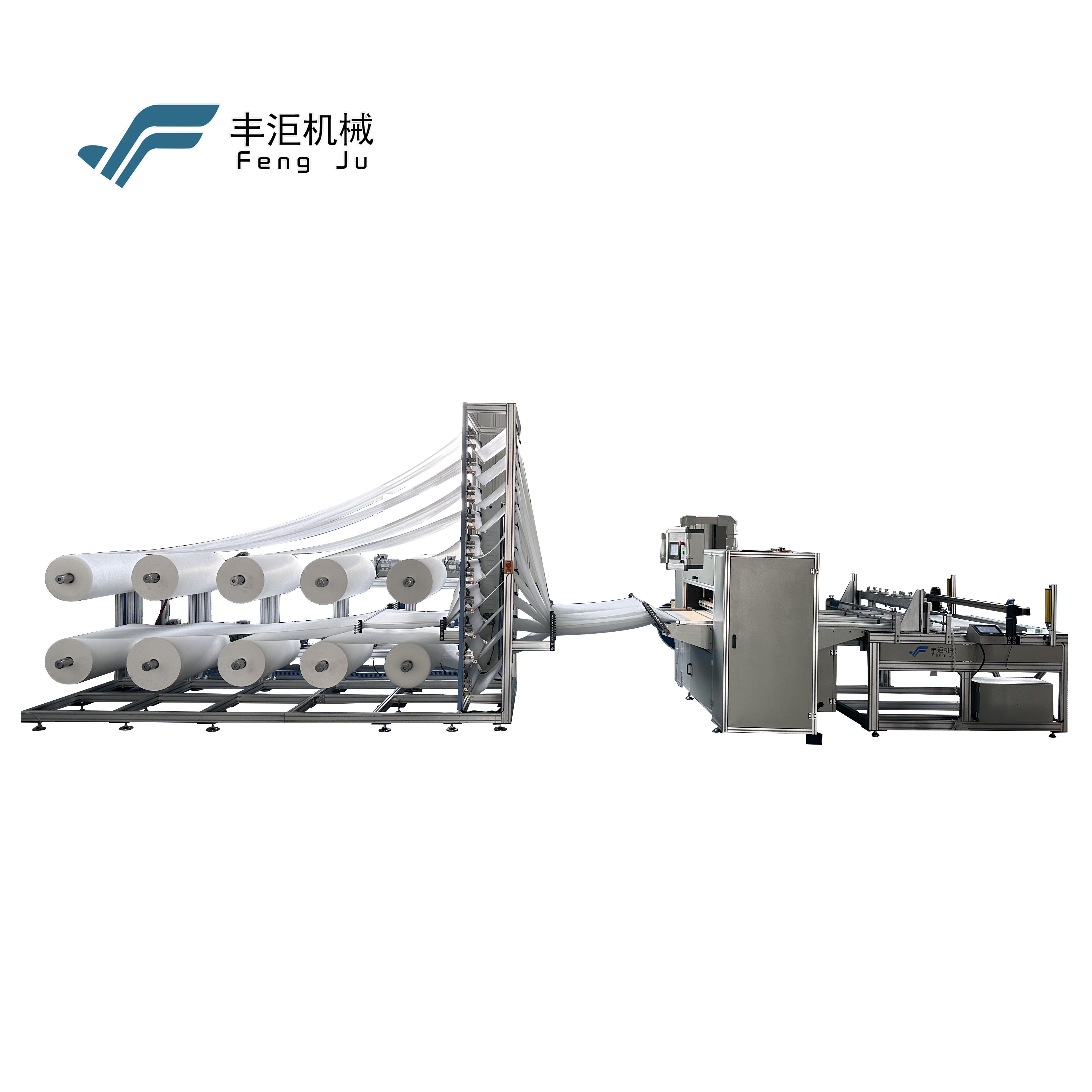

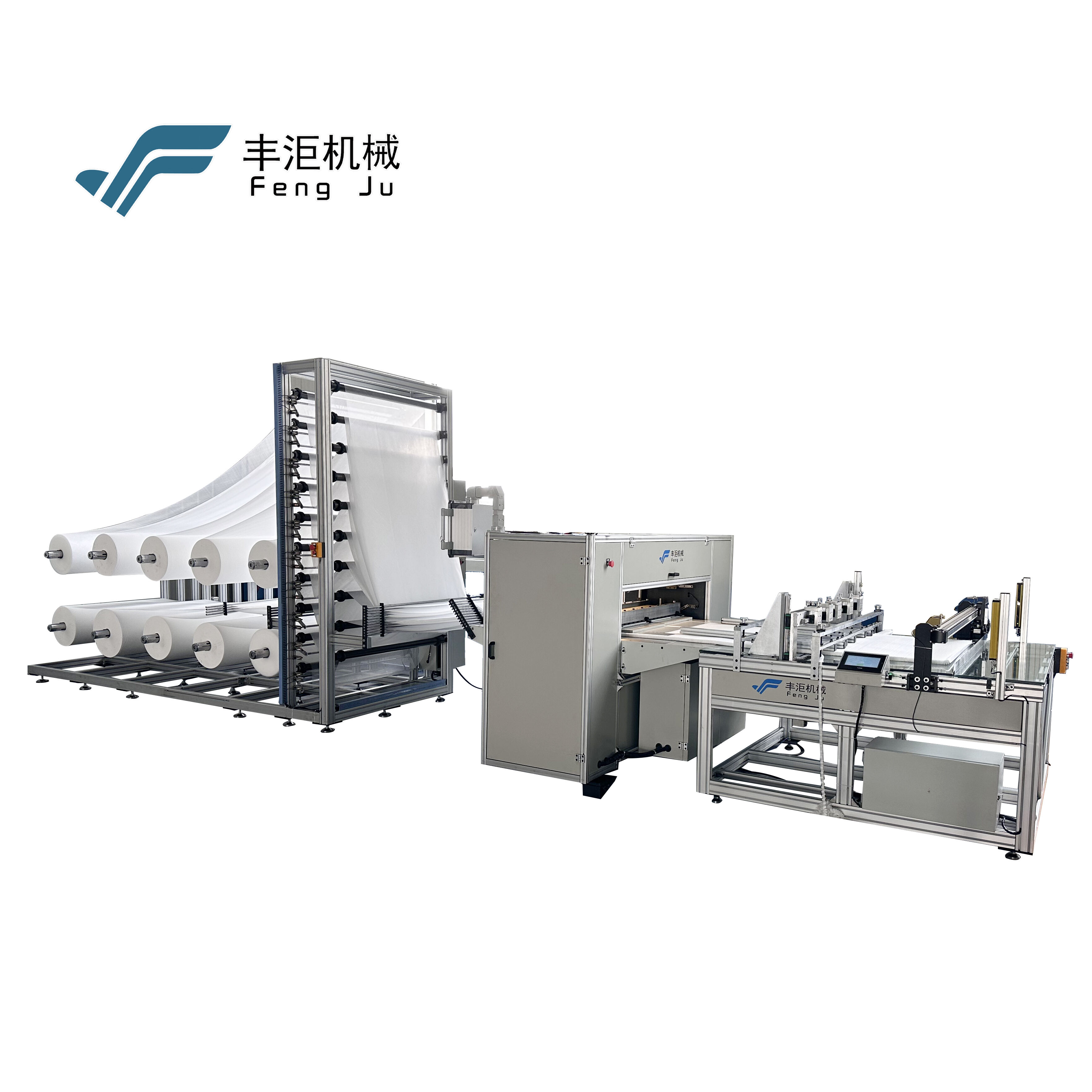

mesh liquid filter pleating machine

The mesh liquid filter pleating machine represents a significant advancement in filtration technology, designed to create precise pleats in mesh filter materials for liquid filtration applications. This sophisticated equipment operates by carefully folding and forming mesh material into uniform pleats, creating a larger surface area for enhanced filtration efficiency. The machine incorporates advanced servo motor control systems that ensure precise pleat depth and spacing, while maintaining consistent material tension throughout the pleating process. Its automated operation includes material feeding, pleat formation, and spacing control, capable of handling various mesh materials ranging from fine stainless steel to synthetic polymers. The machine's versatility allows for customizable pleat heights and depths, making it suitable for producing filters used in industrial processes, water treatment systems, and chemical filtration applications. With adjustable speed controls and programmable settings, operators can optimize production parameters for different mesh specifications and end-product requirements. The system also features advanced safety mechanisms and emergency stops, ensuring operator safety while maintaining high production efficiency.