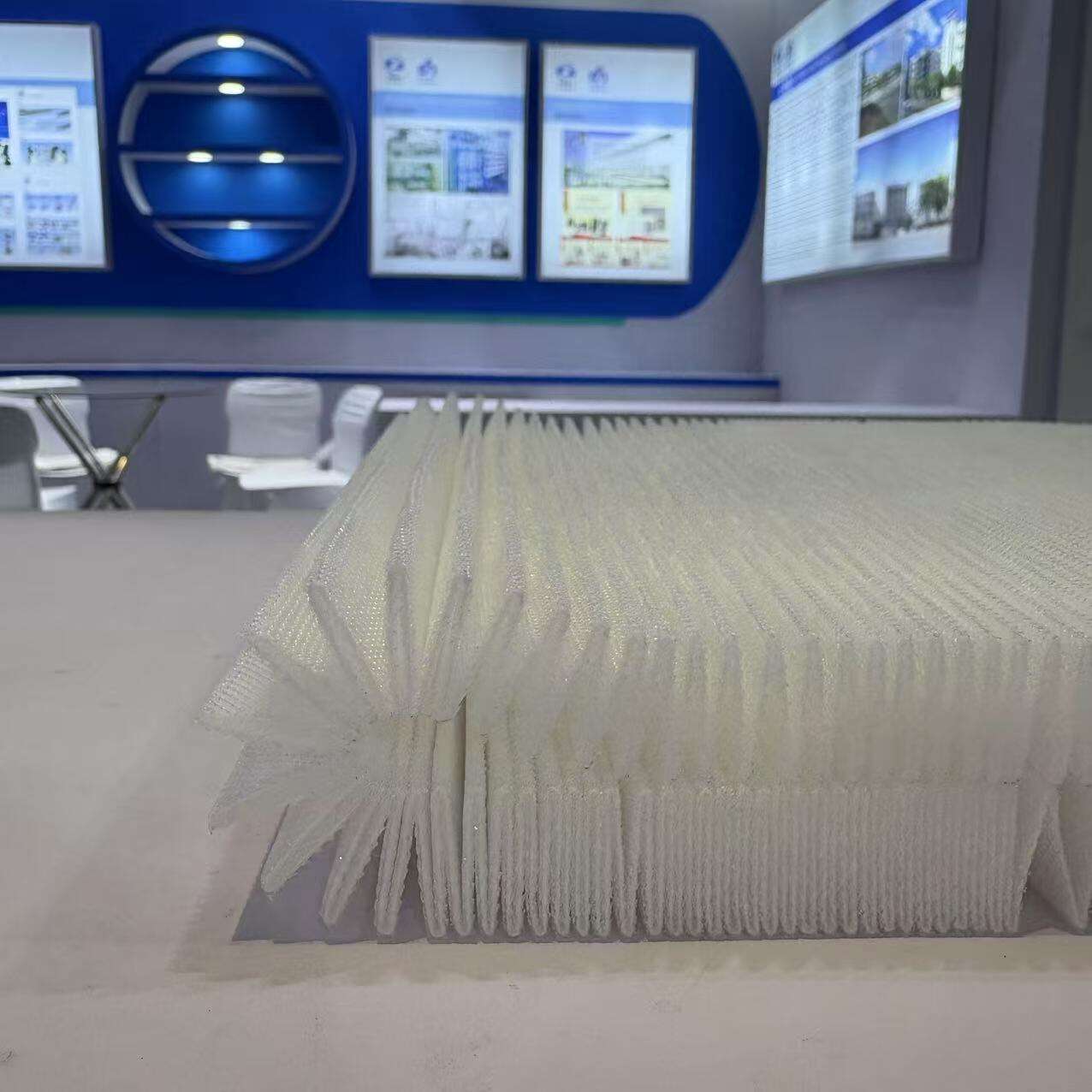

rotary liquid filter pleating machine

The rotary liquid filter pleating machine represents a significant advancement in filtration technology, offering precise and efficient pleating capabilities for liquid filter media. This sophisticated equipment operates through a continuous rotary mechanism that creates uniform pleats in filter materials, ensuring consistent filtration quality. The machine incorporates advanced servo motor controls and precision gear systems to maintain accurate pleat spacing and depth throughout the production process. Its innovative design allows for the processing of various filter media materials, including synthetic fibers, cellulose, and composite materials, making it versatile for different filtration applications. The machine features an automated feeding system that ensures smooth material handling, while its adjustable pleat height and spacing controls enable customization according to specific filtration requirements. The integrated quality control systems monitor pleat formation in real-time, maintaining high production standards. Modern rotary liquid filter pleating machines are equipped with digital interfaces that allow operators to program and monitor production parameters easily. These machines are particularly valuable in industries requiring high-quality liquid filtration, such as pharmaceutical manufacturing, chemical processing, and water treatment facilities.