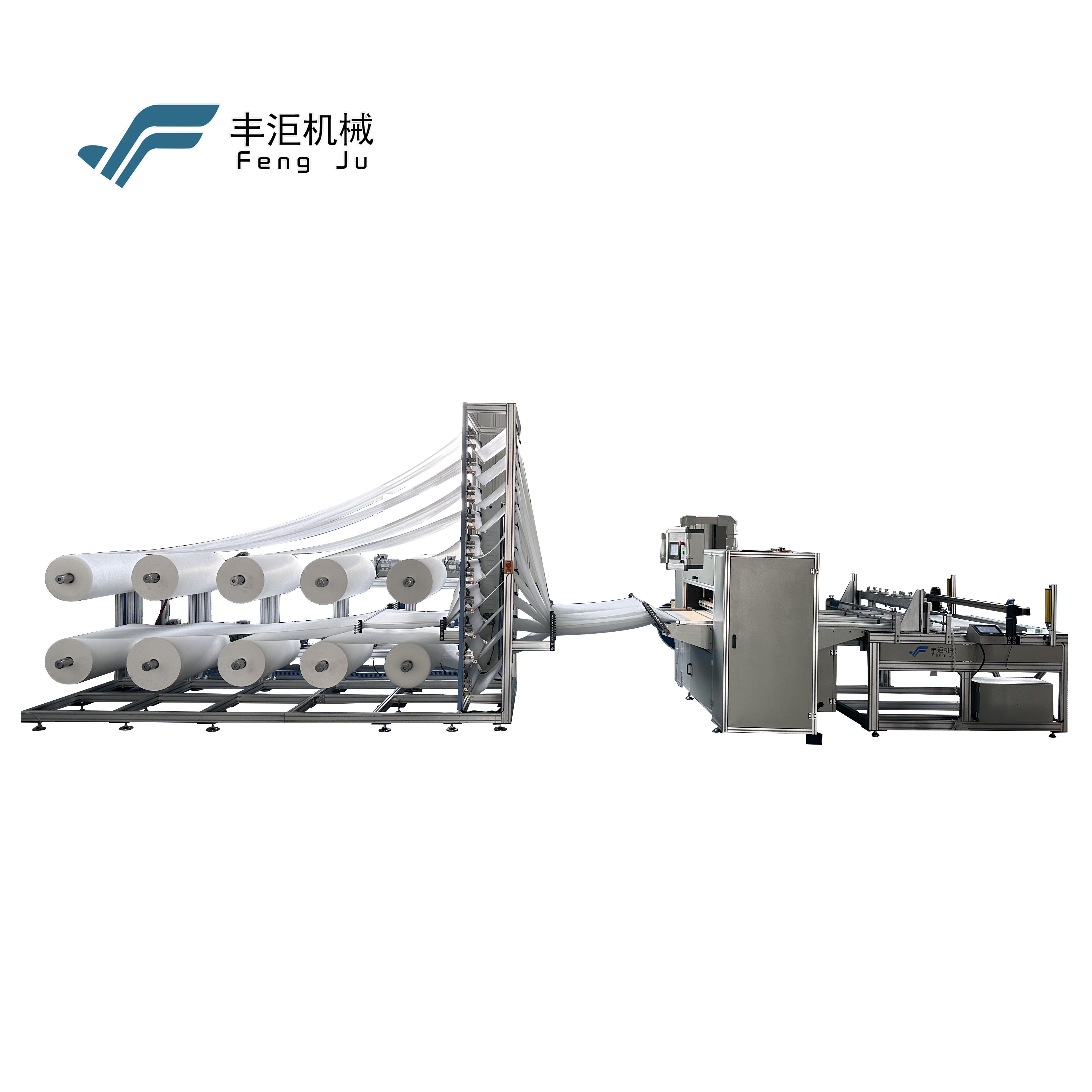

high-speed liquid filter pleating machine

The high-speed liquid filter pleating machine represents a cutting-edge solution in filtration technology, designed to efficiently produce pleated filter elements for liquid filtration applications. This advanced machinery operates by precisely folding filter media into uniform pleats, creating maximum filtration surface area while maintaining consistent pleat height and spacing. The machine incorporates sophisticated servo motor controls and automated tension management systems to ensure precise pleat formation at high production speeds. It handles various filter media materials, including cellulose, synthetic fibers, and composite materials, with thicknesses ranging from 0.2mm to 2.0mm. The machine's innovative design includes real-time pleat monitoring systems and automatic material feeding mechanisms, enabling continuous operation with minimal operator intervention. Key technological features include adjustable pleat depth control, variable speed settings ranging from 5 to 50 meters per minute, and integrated quality control systems that monitor pleat uniformity and structural integrity. These machines are widely applied in manufacturing filters for automotive fluids, industrial processes, water treatment systems, and pharmaceutical applications, where consistent quality and high production efficiency are paramount.