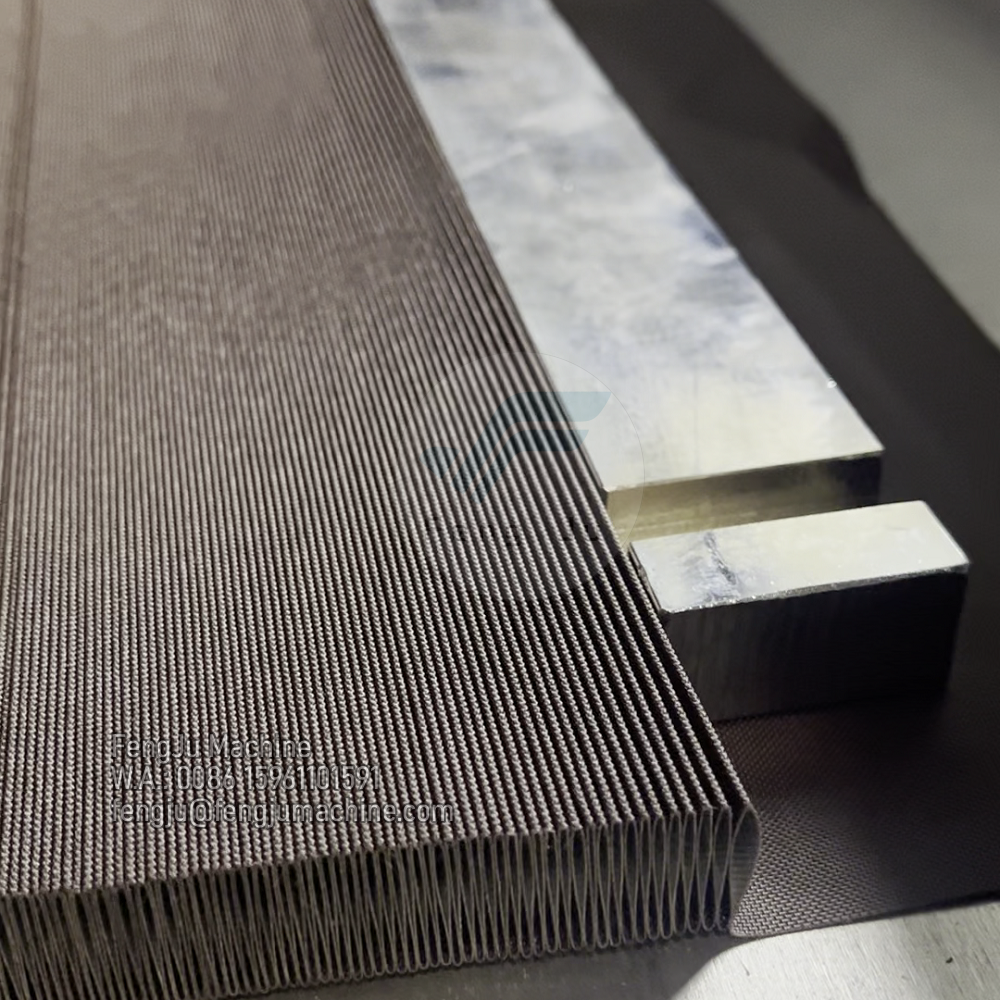

curtain plise machine

The curtain plise machine represents a state of the art solution in automated curtain manufacturing, designed to create precise and consistent pleating patterns in various fabric materials. This sophisticated equipment combines mechanical precision with digital control systems to produce professional grade pleated curtains with exceptional accuracy. The machine features an advanced feeding mechanism that carefully guides fabric through a series of specialized pleating elements, ensuring uniform fold patterns throughout the entire length of the material. It incorporates adjustable settings for pleat depth, spacing, and pattern variations, allowing manufacturers to create diverse styles of pleated curtains to meet different market demands. The technology includes automated tension control systems that maintain consistent fabric tension throughout the pleating process, preventing irregularities and ensuring high quality results. Additionally, the machine is equipped with smart sensors that monitor the pleating process in real time, making automatic adjustments to maintain optimal performance and prevent material waste. Its robust construction and precision engineered components ensure reliability and longevity, while its user friendly interface makes it accessible for operators of varying skill levels.