pleated flyscreen machine factory

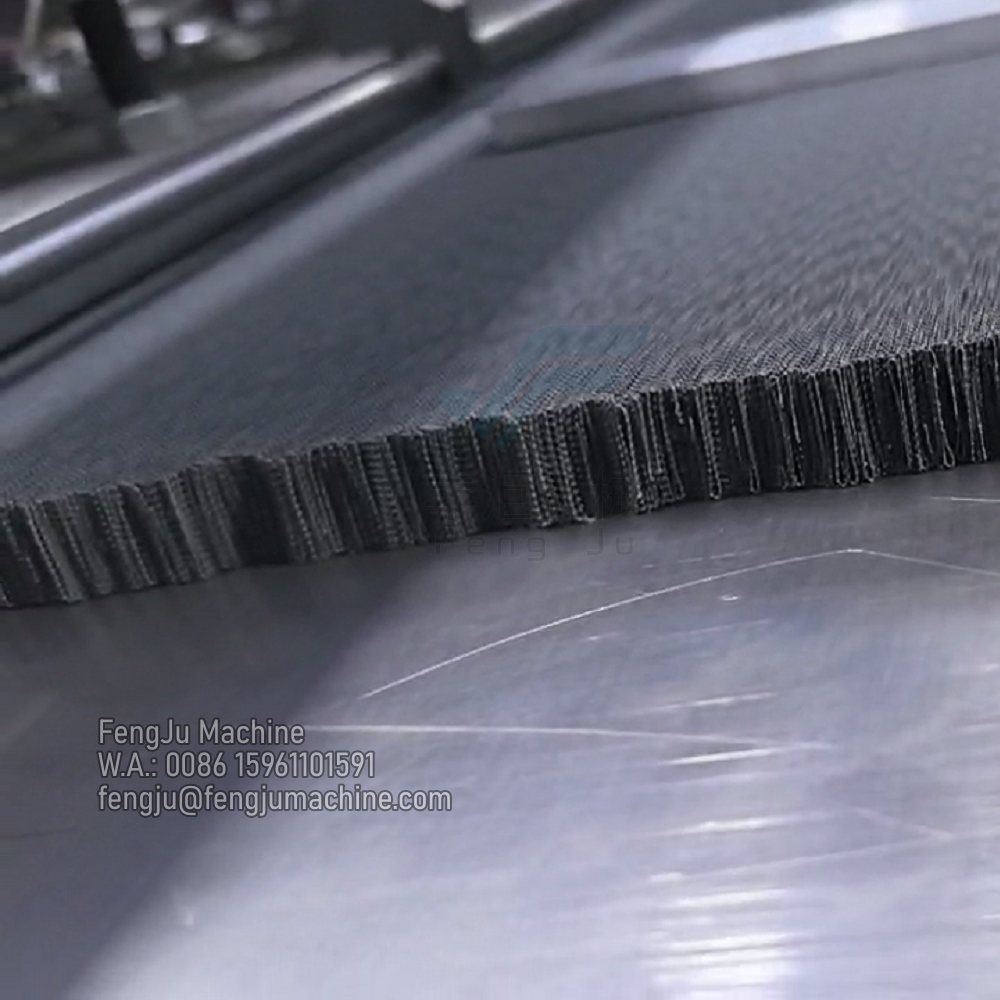

The pleated flyscreen machine factory represents a state-of-the-art manufacturing facility dedicated to producing high-precision equipment for the creation of pleated insect screens. This advanced facility combines innovative technology with efficient production processes to deliver reliable and consistent results. The factory specializes in manufacturing automated machinery that handles the entire pleated screen production process, from material feeding to finished product packaging. The facility's core capabilities include precision pleating systems, automated cutting mechanisms, and quality control stations that ensure each machine meets stringent performance standards. With computer-controlled operations and real-time monitoring systems, the factory maintains exceptional quality control throughout the production cycle. The facility's production line incorporates advanced assembly stations, testing areas, and calibration zones, ensuring each machine delivers optimal performance. The factory's technical capabilities extend to customization options, allowing for the production of machines that can handle various screen materials and sizes. Additionally, the facility houses research and development departments that continuously work on improving machine efficiency and incorporating new technologies. This comprehensive approach to manufacturing ensures that each pleated flyscreen machine meets modern industry requirements while maintaining cost-effectiveness and reliability.