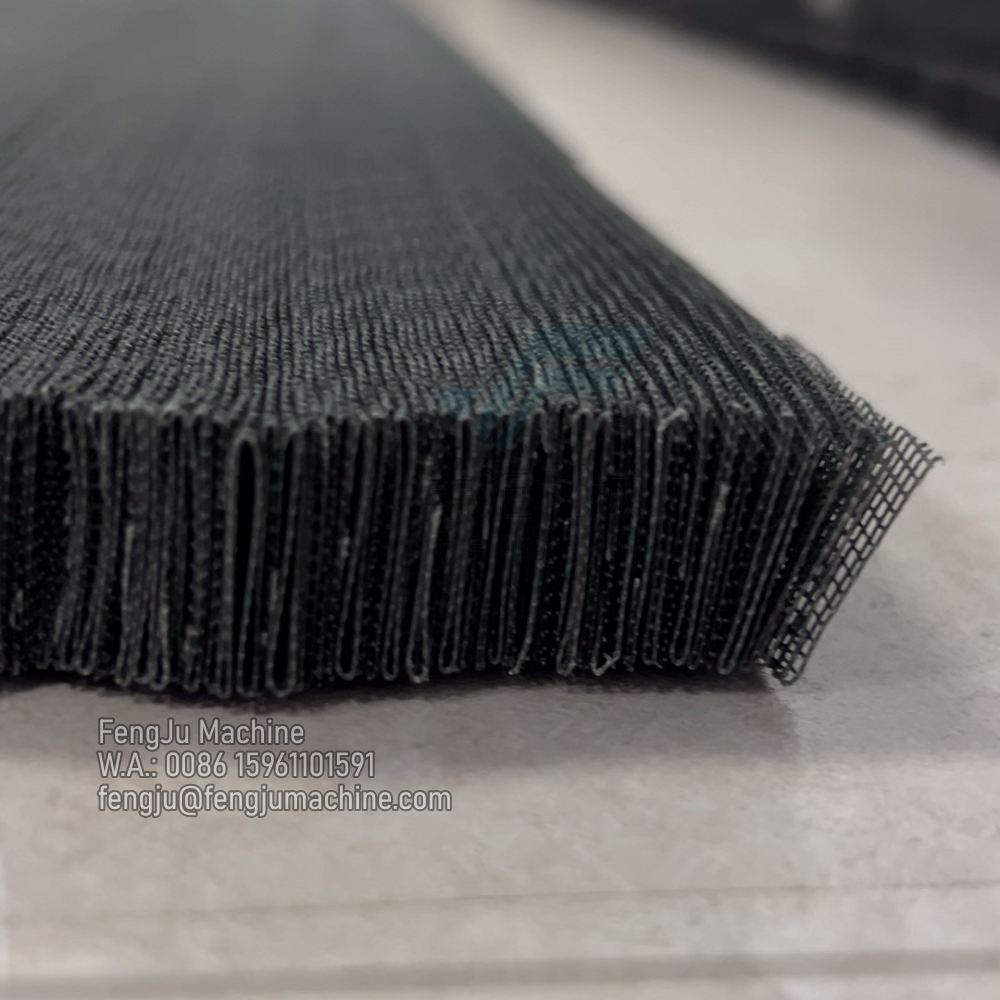

insect screen pleating machine

The insect screen pleating machine represents a groundbreaking advancement in window screen manufacturing technology. This sophisticated equipment automates the precise folding and pleating of mesh materials used in window and door screens, ensuring consistent quality and enhanced productivity. The machine operates through a synchronized system of rollers and pressing mechanisms that carefully form uniform pleats in the screen material, maintaining exact specifications throughout the process. Its advanced control system allows operators to adjust pleat sizes, pressure settings, and production speeds to accommodate different mesh materials and end-product requirements. The machine features an automated feeding system that smoothly guides the material through the pleating process, while integrated tension control ensures the material remains properly aligned. Built with industrial-grade components, the system includes safety features such as emergency stops and protective guards. The pleating mechanism employs precision-engineered dies that create sharp, durable folds without damaging the mesh structure. This technology significantly reduces manual labor requirements while increasing output capacity and maintaining consistent product quality. The machine's versatile design allows it to handle various mesh materials, including fiberglass, aluminum, and synthetic fabrics, making it suitable for diverse manufacturing applications.