china mosquito net pleating machine

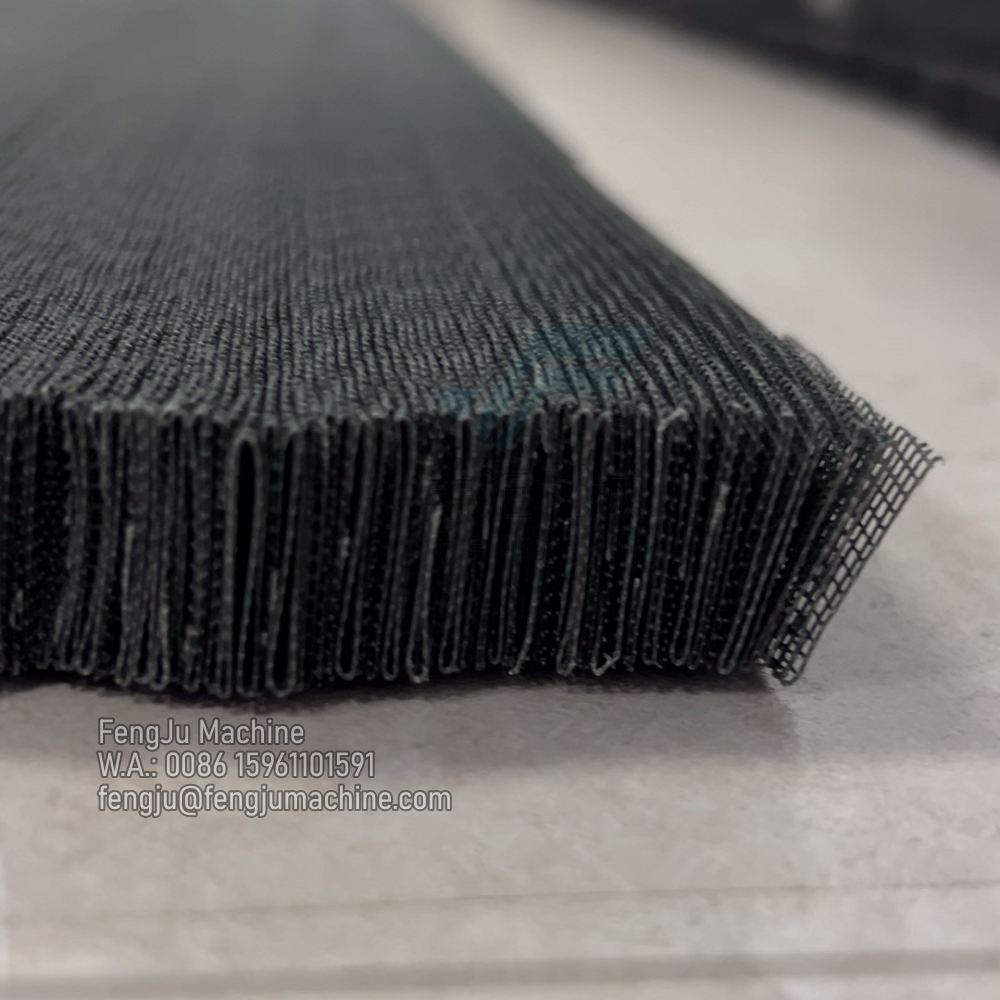

The China mosquito net pleating machine represents a significant advancement in textile manufacturing technology, specifically designed for the efficient production of pleated mesh materials. This sophisticated equipment automates the intricate process of creating precise, uniform pleats in mosquito netting material, ensuring consistent quality and high production output. The machine features advanced servo motor controls that maintain precise pleating patterns while operating at optimal speeds of up to 100 meters per hour. Its innovative design incorporates a heating system that helps set the pleats permanently, resulting in durable, well-defined folds that maintain their shape over time. The machine accommodates various mesh materials and can be adjusted to create different pleat sizes, typically ranging from 20mm to 30mm in width. Built with industrial-grade components, the system includes automatic fabric feeding mechanisms, tension control systems, and computerized pattern controls that minimize human intervention and reduce production errors. The machine's versatility allows it to handle different fabric widths, generally ranging from 1.6 to 2.3 meters, making it suitable for various commercial applications. Safety features include emergency stop buttons, overload protection, and transparent safety guards that protect operators while allowing visual monitoring of the pleating process.