water filter pleating machine

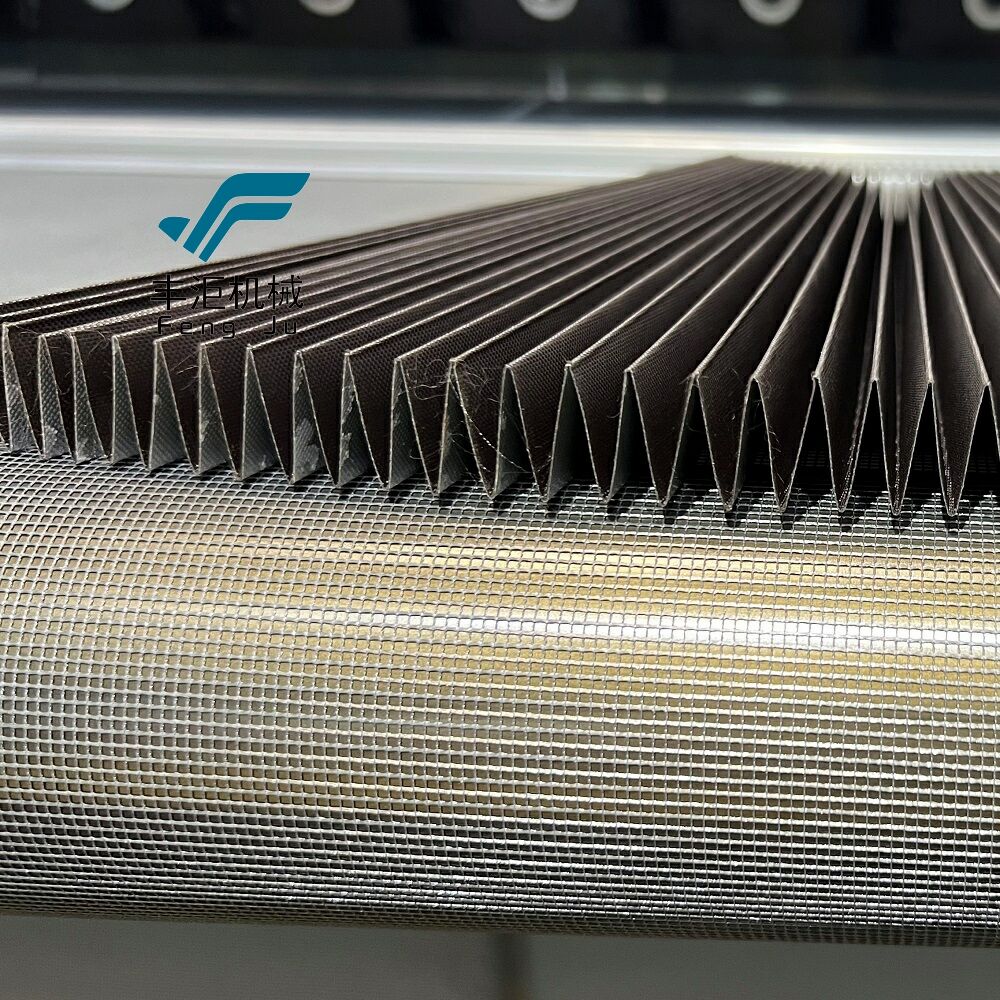

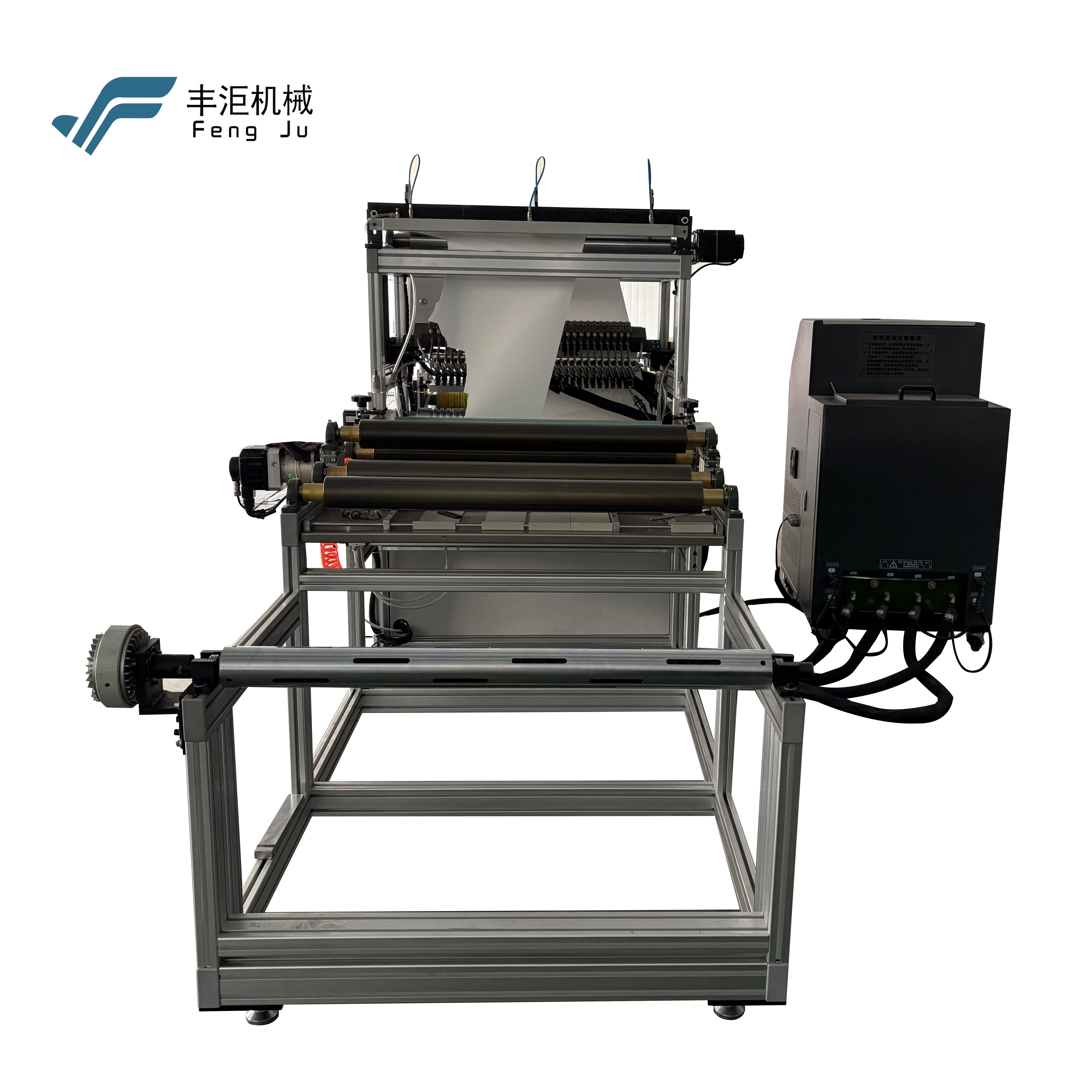

The water filter pleating machine represents a cutting-edge solution in the filtration industry, designed to create precise pleated filter elements essential for water purification systems. This sophisticated equipment employs advanced mechanical and automation technologies to transform flat filter media into uniformly pleated structures. The machine operates through a systematic process that begins with feeding filter material through precision-guided rollers, followed by the creation of consistent pleats using specialized scoring and folding mechanisms. The pleating process is meticulously controlled by computerized systems that ensure exact pleat depth, spacing, and height parameters. Operating at speeds of up to 50 meters per minute, these machines can accommodate various filter media materials, including polypropylene, polyester, and fiberglass. The technology incorporates adjustable pleat spacing mechanisms, allowing for customization between 1.5 to 25 millimeters, making it versatile for different filtration requirements. Advanced features include automatic tension control, real-time pleat counting, and integrated quality monitoring systems that maintain consistency throughout production runs. The machine's applications extend across industrial water treatment, residential water purification, and specialized filtration needs in pharmaceutical and food processing industries.