semi-automatic filter pleating machine

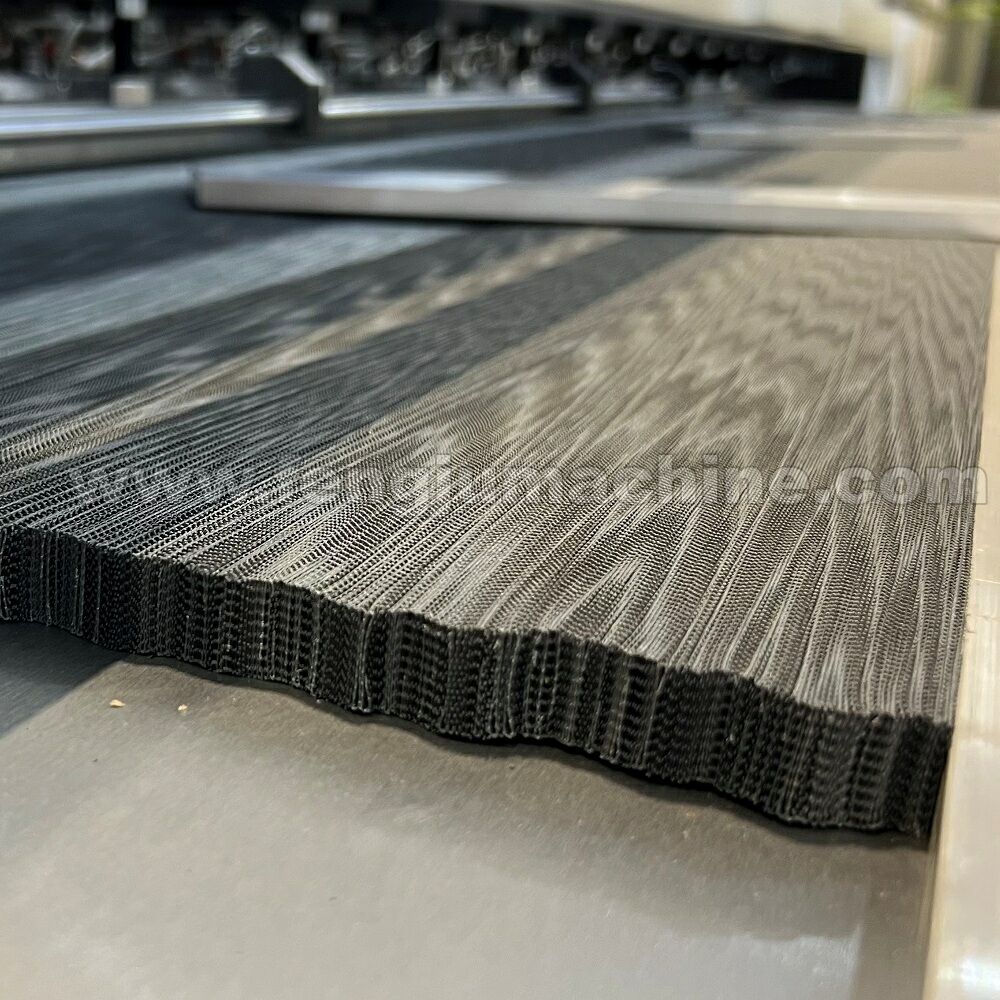

The semi-automatic filter pleating machine represents a significant advancement in filtration technology manufacturing. This sophisticated equipment is designed to create precise pleats in various filter materials, ensuring consistent quality and dimensional accuracy. The machine operates through a combination of mechanical and electronic systems, allowing operators to adjust pleat height, depth, and spacing according to specific requirements. Its primary functions include material feeding, pleat formation, and controlled output of pleated media. The machine incorporates advanced scoring mechanisms that create precise fold lines, ensuring uniform pleat geometry essential for optimal filter performance. Temperature-controlled heating elements maintain proper material conditioning during the pleating process, while the adjustable speed control system enables operators to optimize production rates based on material characteristics. The semi-automatic design strikes an ideal balance between automation and operator control, making it suitable for both small-batch production and medium-scale manufacturing operations. Applications span across various industries, including HVAC systems, automotive filters, industrial air filtration, and clean room environments. The machine accommodates different filter media types, from synthetic materials to fiberglass and specialized filter papers, with thicknesses ranging from 0.2mm to 2.0mm.