rotary filter pleating machine

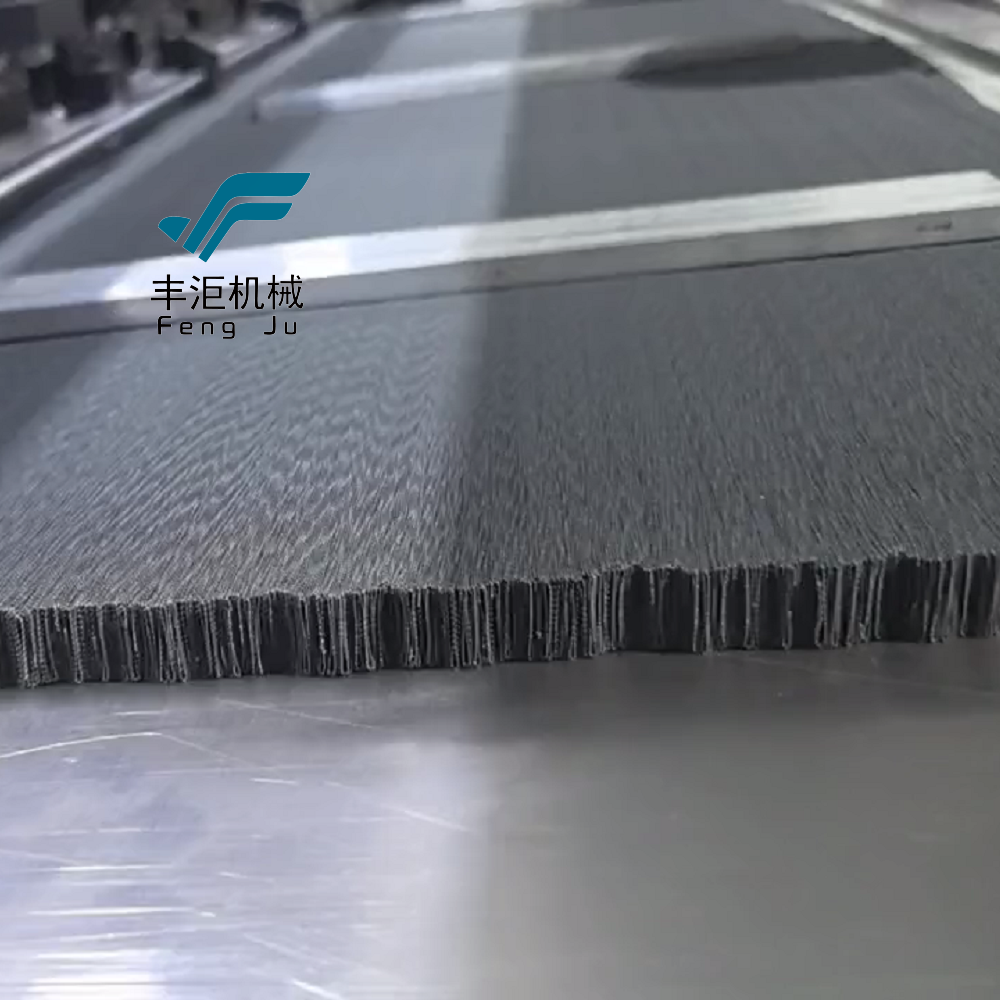

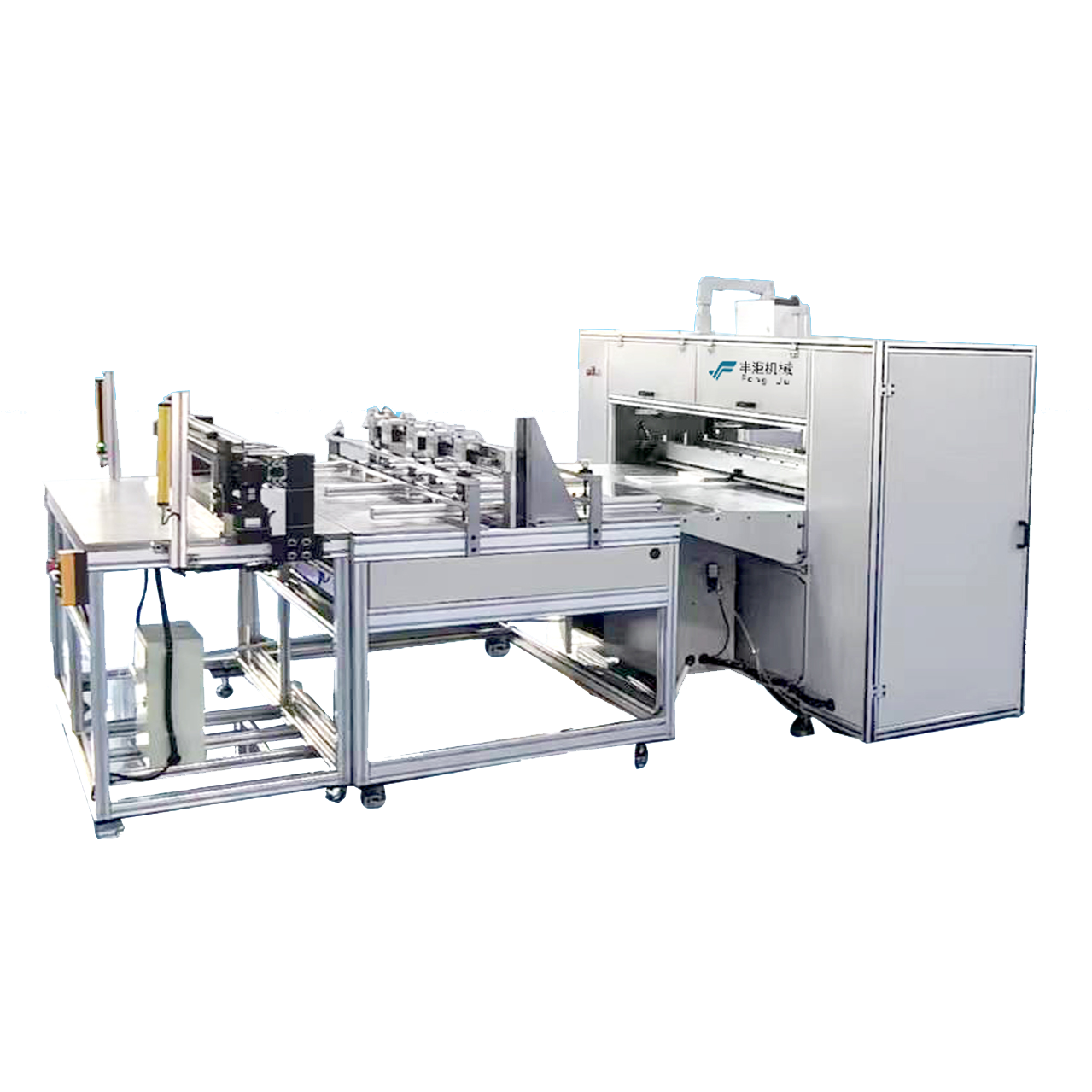

The rotary filter pleating machine represents a pinnacle of advanced filtration technology, designed to create precise and uniform pleats in filter media with exceptional consistency. This sophisticated equipment operates through a rotary mechanism that automatically feeds, scores, and pleats various filter materials, including paper, synthetic media, and composite materials. The machine's core functionality revolves around its ability to create precise pleat geometries through a combination of rotary scoring wheels and specialized forming tools. Operating at high speeds while maintaining precision, these machines can handle multiple filter media widths and accommodate various pleat heights and depths. The technology incorporates advanced tension control systems that ensure uniform pleat formation and prevent material distortion during the pleating process. Its programmable control interface allows operators to adjust key parameters such as pleat depth, spacing, and production speed to meet specific filtration requirements. The machine's applications span across numerous industries, including automotive air and oil filtration, HVAC systems, industrial air purification, and medical device manufacturing. The rotary pleating system's design also includes automatic material tracking and alignment features that minimize waste and ensure consistent product quality. With its robust construction and precision engineering, the rotary filter pleating machine delivers reliable performance in high-volume production environments while maintaining the flexibility to accommodate custom pleating specifications.