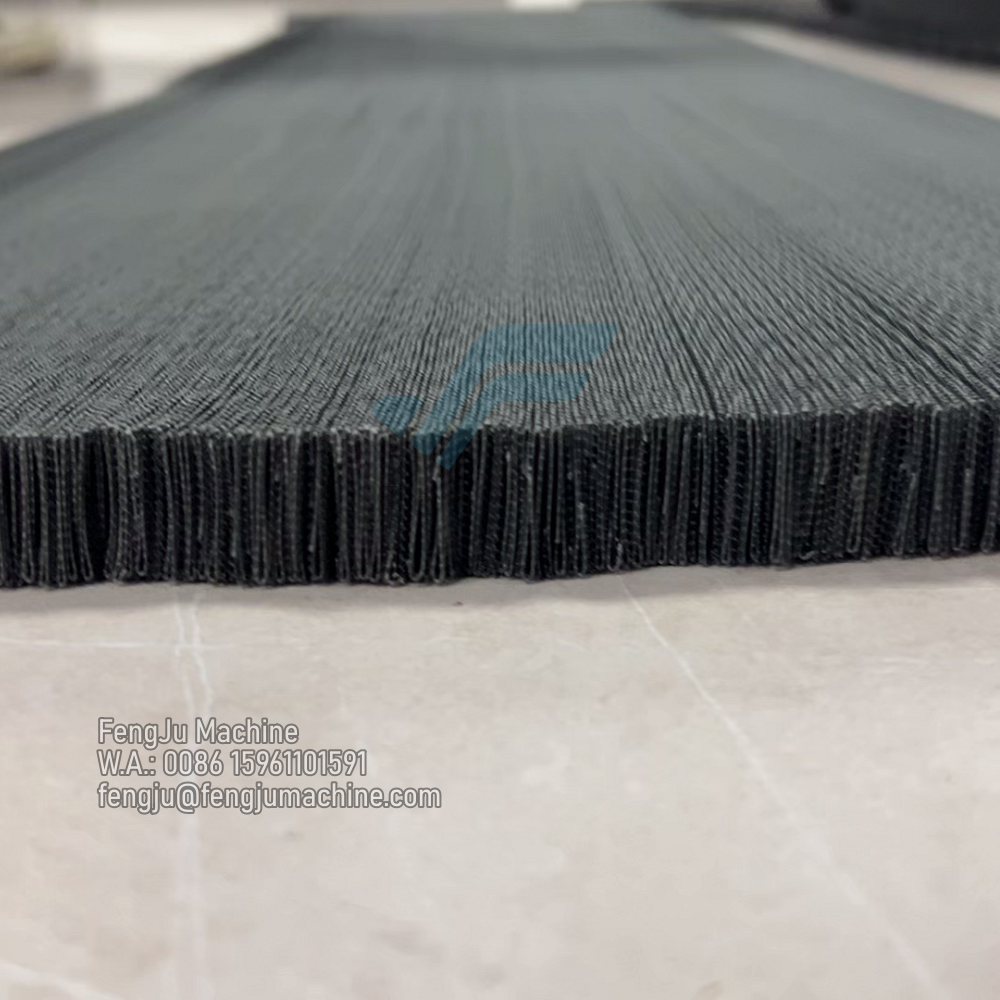

screen mesh pleating machine

The screen mesh pleating machine represents a significant advancement in industrial filtration technology, designed specifically for the precise and efficient pleating of various mesh materials. This sophisticated equipment operates through a carefully calibrated system that creates uniform, accurate pleats in screen mesh materials, ensuring consistent quality and optimal performance. The machine incorporates advanced servo motor controls and precision measurement systems to maintain exact pleat depths and spacing, crucial for producing high-quality filtration products. Its versatile design accommodates different mesh types and sizes, from fine stainless steel mesh to synthetic materials, making it invaluable across multiple industries. The machine features automated feed mechanisms that ensure smooth material handling and prevent damage to delicate mesh materials during the pleating process. Additionally, it includes adjustable speed controls and pleat depth settings, allowing operators to customize production parameters according to specific requirements. The screen mesh pleating machine's robust construction ensures long-term reliability and consistent performance, while its user-friendly interface simplifies operation and maintenance procedures. This equipment proves essential in manufacturing various filtration products, including air filters, liquid filters, and specialized industrial screening applications.