pleated flyscreen machine

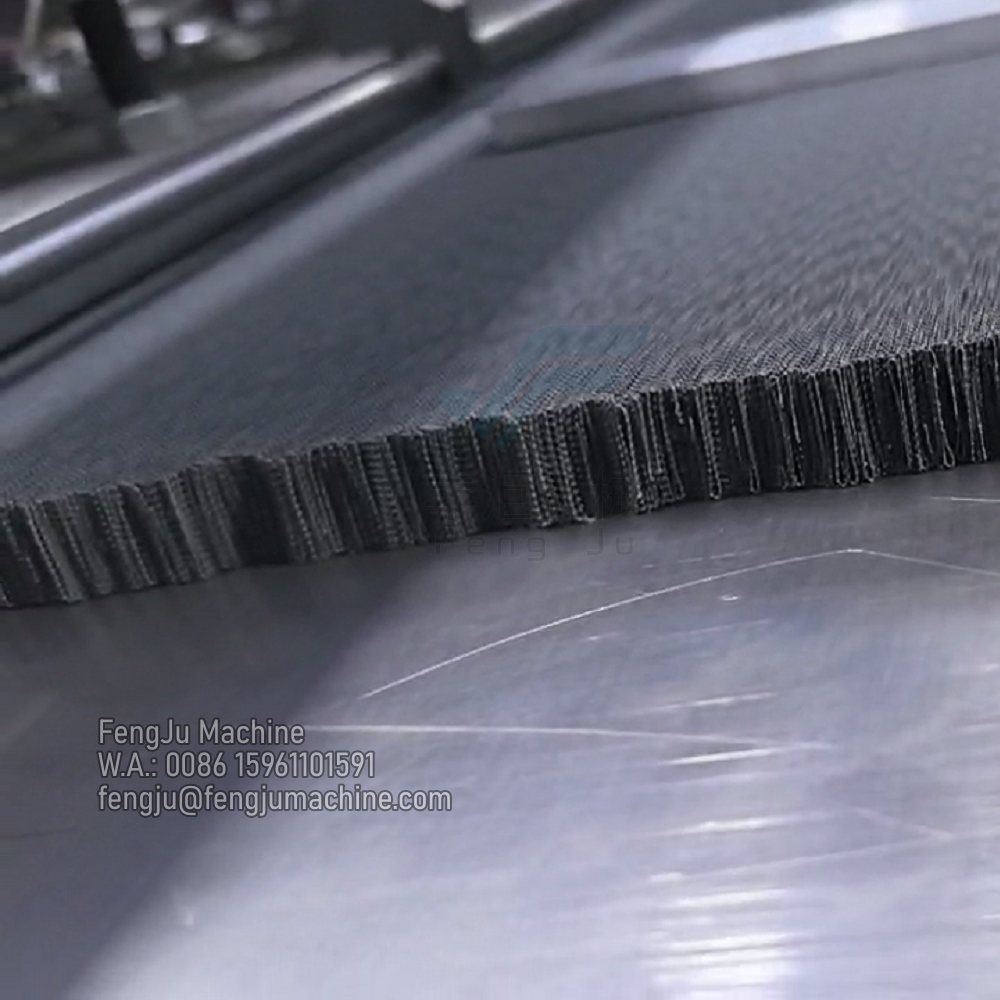

The pleated flyscreen machine represents a cutting-edge solution in the manufacturing of pleated insect screens, combining precision engineering with automated efficiency. This advanced machinery employs sophisticated pleating technology to create durable, retractable screens that offer superior protection against insects while maintaining optimal airflow. The machine's core functionality includes automated material feeding, precise pleating mechanisms, and quality control systems that ensure consistent production output. It features computerized control panels that allow operators to adjust pleating dimensions, tension settings, and production speeds according to specific requirements. The machine can process various screen materials, including fiberglass, polyester, and aluminum mesh, with exceptional accuracy and minimal waste. Its innovative design incorporates multiple processing stations, from initial material preparation to final product packaging, streamlining the entire manufacturing process. The system's modular construction allows for easy maintenance and quick component replacement, minimizing downtime and maximizing productivity. Additionally, the machine includes advanced safety features and emergency stop mechanisms, ensuring operator protection while maintaining high production standards. This versatile equipment serves various applications, from residential window screens to commercial and industrial installations, making it an essential tool for screen manufacturers aiming to meet diverse market demands.