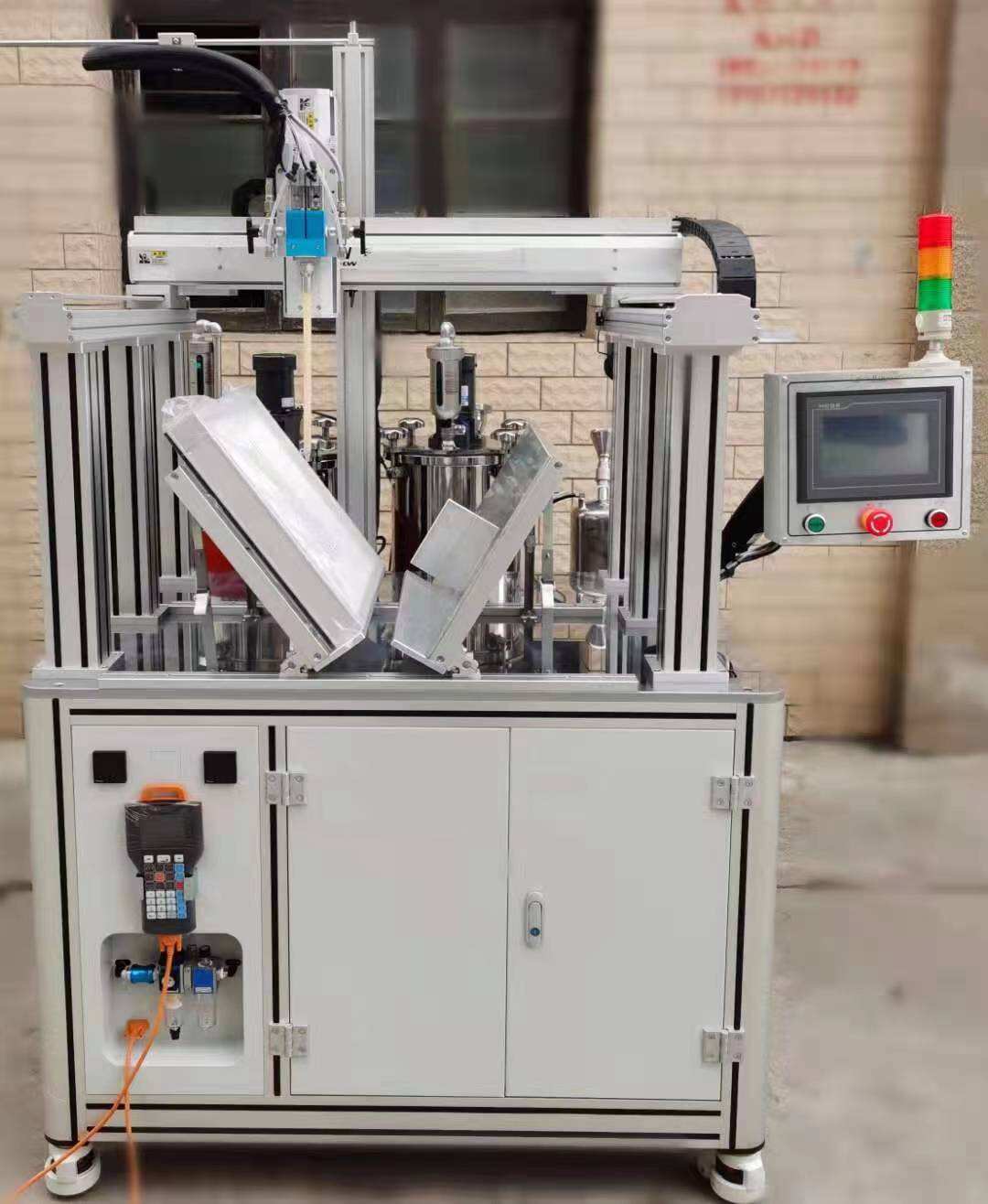

pu gluing system

The PU gluing system represents a cutting-edge solution in adhesive technology, designed to deliver precise and efficient polyurethane adhesive application across various industrial processes. This sophisticated system combines advanced dispensing mechanisms with intelligent control systems to ensure accurate adhesive placement and optimal bond strength. At its core, the system features precision pumps that maintain consistent material flow, temperature-controlled reservoirs that preserve adhesive properties, and programmable dispensing patterns that accommodate different product geometries. The technology incorporates smart monitoring capabilities that track adhesive consumption, application patterns, and system performance in real-time. The system's versatility allows it to handle both one-component and two-component polyurethane adhesives, making it suitable for diverse manufacturing applications, from furniture assembly to automotive components. Advanced features include automatic viscosity compensation, precise mixing ratios for multi-component adhesives, and integrated quality control measures that ensure proper cure times and bond strength. The system's modular design facilitates easy maintenance and quick changeovers between different adhesive types, while its automated cleaning cycles minimize downtime and maintain optimal performance.