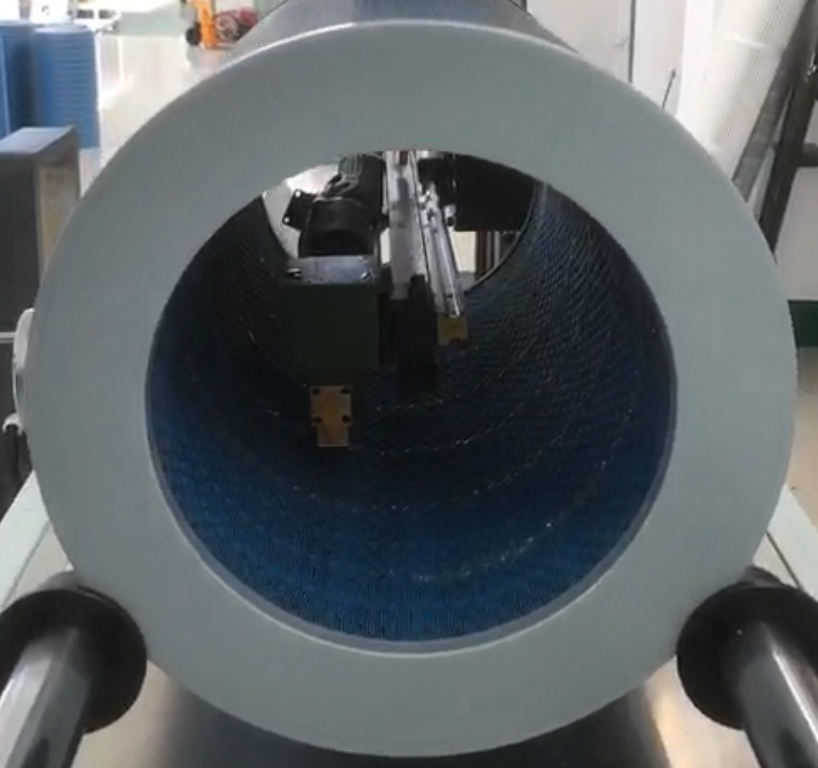

gluing system

A gluing system represents a sophisticated automated solution designed for precise adhesive application across various manufacturing processes. This comprehensive system integrates advanced dispensing technology, precise control mechanisms, and intelligent monitoring capabilities to ensure consistent and accurate adhesive application. The system typically comprises multiple components, including dispensing units, pressure regulators, material feeding systems, and programmable controllers that work in harmony to deliver optimal bonding results. Modern gluing systems incorporate sensor technology for real-time monitoring of adhesive viscosity, temperature, and flow rate, ensuring maintained quality standards throughout the production process. These systems can handle various adhesive types, from hot melts to two-component epoxies, making them versatile for different industrial applications. The technology enables customizable application patterns, controlled dispensing volumes, and automated operation sequences, significantly reducing manual intervention and increasing production efficiency. Industries such as packaging, woodworking, automotive, and electronics manufacturing benefit from these systems' ability to deliver precise, repeatable results while minimizing material waste and optimizing adhesive consumption.