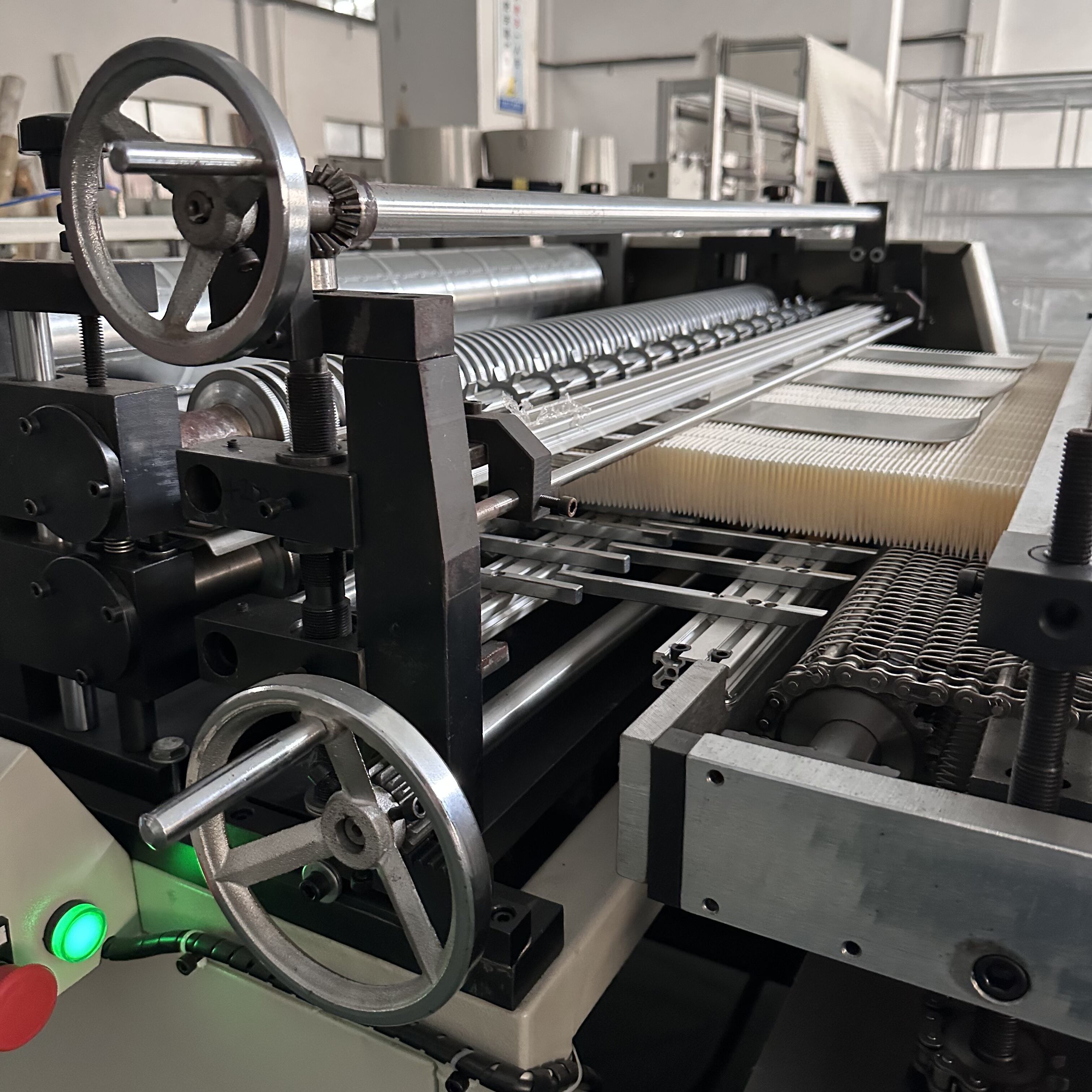

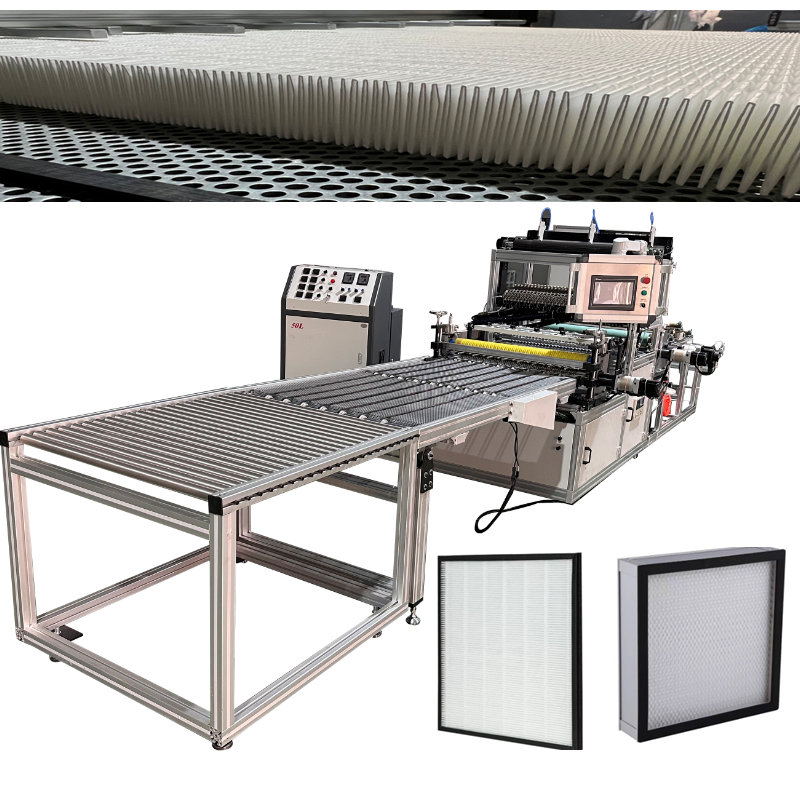

mini filter pleating machine

The mini filter pleating machine represents a significant advancement in filtration technology, offering a compact yet powerful solution for manufacturing pleated filters. This sophisticated equipment efficiently creates precise pleats in various filter media materials, including paper, polyester, and fiberglass. The machine operates through a carefully synchronized system of feed rollers, scoring blades, and pleat formation mechanisms, ensuring consistent pleat depth and spacing. Its automated process maintains precise pleat heights ranging from 12mm to 50mm, while the adjustable pleat density control allows for customization based on specific filtration requirements. The machine's compact design makes it ideal for facilities with limited space, while its digital control interface enables operators to easily adjust parameters such as pleating speed, depth, and spacing. Operating at speeds of up to 15 meters per minute, it significantly enhances production efficiency while maintaining exceptional pleat quality. The machine incorporates advanced safety features, including emergency stop buttons and protective guards, ensuring operator safety during operation. Its versatility makes it suitable for producing various filter types, from HVAC filters to automotive air filters, making it an essential tool for filter manufacturers of all sizes.