3200mm window mesh pleating machine manufacturer

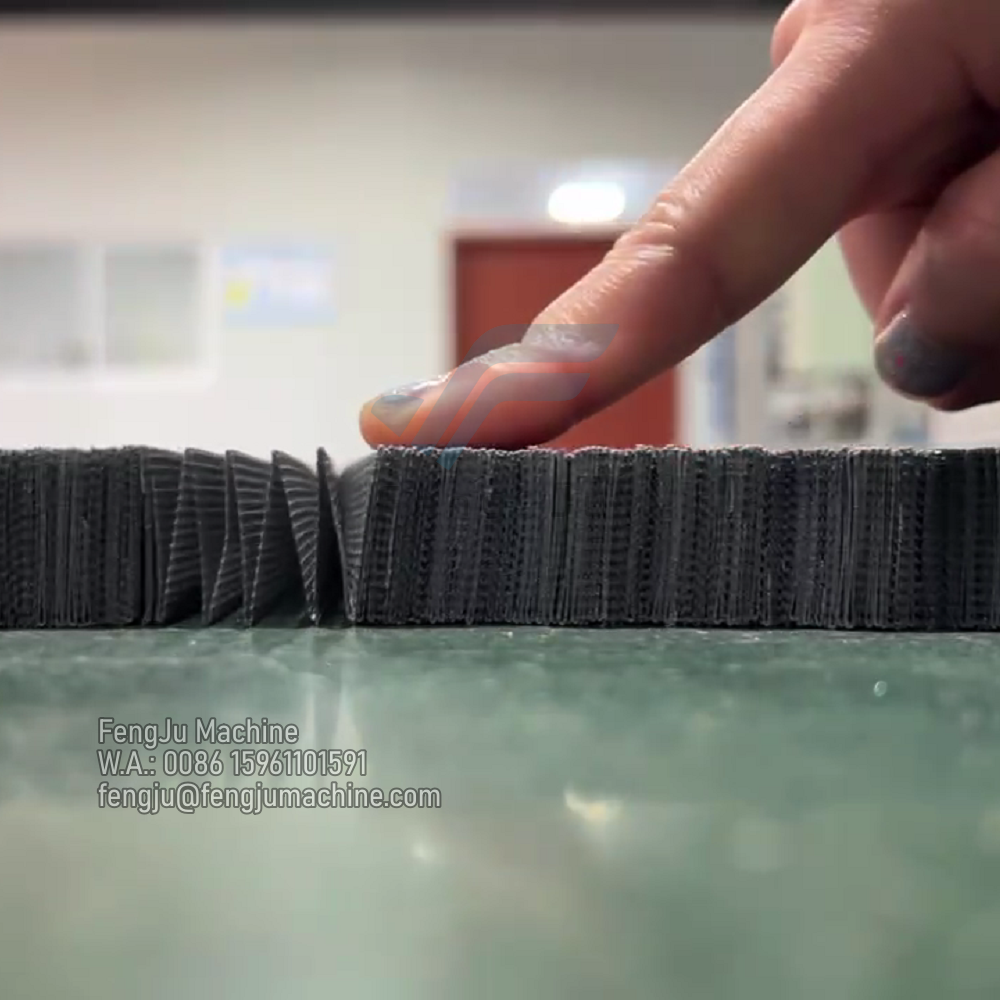

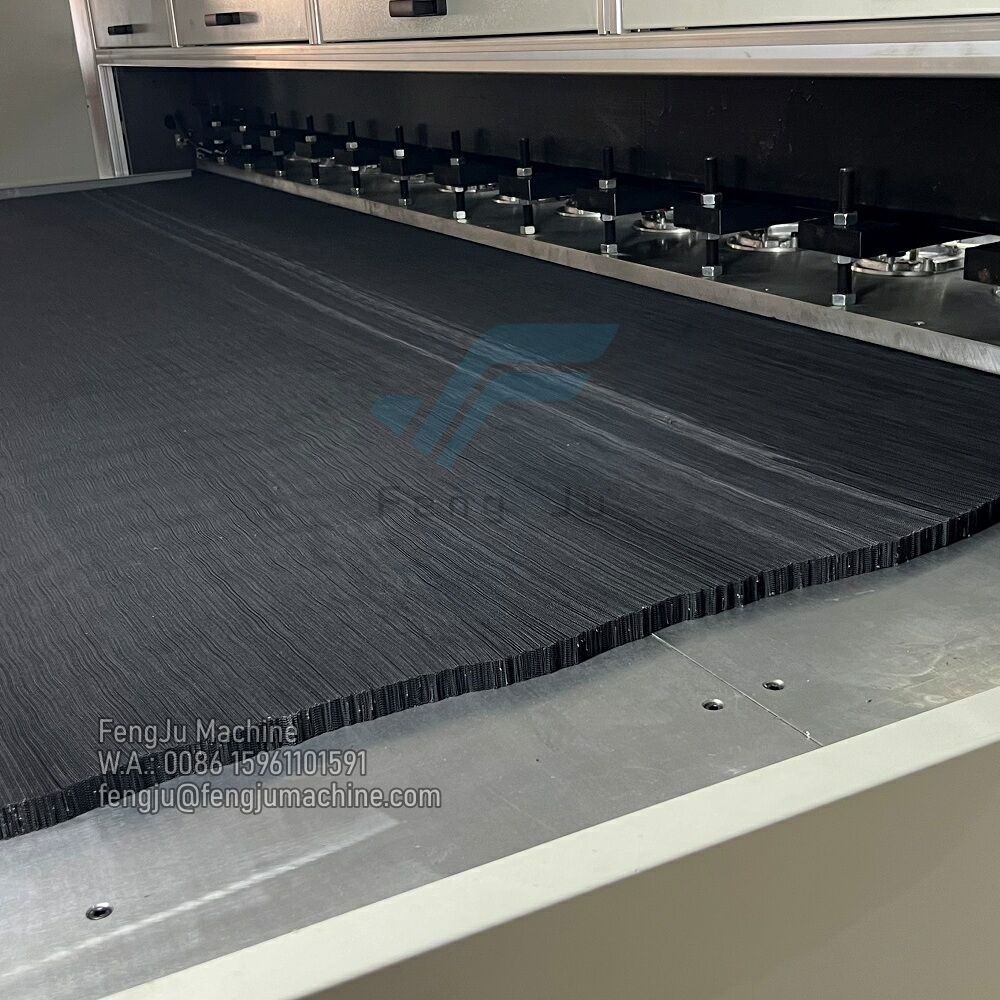

The 3200mm window mesh pleating machine manufacturer stands at the forefront of industrial innovation, delivering state-of-the-art equipment for precise pleating of window screening materials. This advanced machinery specializes in creating uniform, durable pleats in mesh materials up to 3200mm in width, making it ideal for large-scale commercial production. The machine incorporates cutting-edge servo motor technology for precise control and consistent pleating patterns, while its automated feeding system ensures continuous operation with minimal manual intervention. The manufacturer has implemented sophisticated tension control mechanisms that maintain optimal material stability throughout the pleating process, resulting in high-quality finished products. The system features adjustable pleating depths and spacing options, allowing manufacturers to customize their output according to specific customer requirements. With an industrial-grade stainless steel construction and premium components, these machines are built for longevity and reliable performance in demanding production environments. The manufacturer also provides comprehensive technical support, including installation, training, and maintenance services to ensure optimal machine performance and productivity.